The first three photos were taken on LHA5Z Gantry type I Beam Welding Machine working at different steel structure facilities. You can judge its control style at first glance: Operator stands at center of this H Beam Gantry Welding Machine.

1. Variations in Control Style and Dimension of LHA Series Gantry type H Beam Welding Machine:

1) Among the three types of H Beam Submerged Arc Welding Machine, the LHA gantry type H Beam Welding Machine is the only one that has many variations in terms of operator station (center control LHAZ versus side control LHAC), and rail span(4m, 5m, 5.5m): (Fig.1)

2) Such variation in I Beam Gantry Welding Machine is determined by feature of its machine frame structure: Gantry is a kind of closed one, which poses restriction on both H Beam size and operating station. Instead, both column type (LHC) H Beam Welding Machine and T type (LHT) Gantry type H Beam Submerged Arc Welding Machine has open type machine body, which has no such confinement.

2. Strong Points and Limitation of LHAZ Series Gantry type H Beam Welding Machine:

1) Strong Points of LHAZ Series H Beam Gantry Welding Machine:

Of which the LHA5Z is the most often selected model of automatic H Beam Gantry Welding Machine. This is because:

a) LHA5Z I Beam Welding Machine can weld H Beam with web size up to 1800mm, meeting majority H Beam production demand;

b) Center control LHAZ Gantry type H Beam Welding Machine need only one operator to take care the SAW (Submerged arc welding) process;

2) Limitation of Gantry type I Beam Welding Machine:

Of course, every solution has its advantage and disadvantage. For center control gantry type H Beam welding machine, two obvious shortcomings are:

a) As explained, the same rail span of LHAZ has smaller H Beam size than side control LHAC: For this 5m rail span, with LHA5C automated gantry type H Beam welding machine, the biggest H Beam web width can be up to 2000mm, compared with 1800mm for LHA5Z;

b) Another is operation inconvenience for operator. As can be conceived from the sketch, for side control of LHAC H Beam Gantry Welding Machine, operator stands at outside of H Beam, which is easy for operator to move around for various action, such as fetching a tool, checking and confirming a condition, etc.: (Fig.2)

c) While for operator of LHAZ center control Gantry type I Beam Welding Machine, standing in the middle of the machine beneath the gantry and between the two pieces of parallel rails, he or she needs to make a detour in further distance to accomplish the tasks: (Fig.3)

3. Configuration of LHAZ Series H Beam Gantry Welding Machine:

Taking LHA5Z as example, this is the complete configuration for a set of high efficiency gantry type H Beam welding machine:

1) Machine body--- Gantry frame, two sets of travel carriage for fitting welding torch, wire feeding tube and attachments;

2) Rail--- Two pieces in parallel, for guiding gantry travel along H Beam and perform SAW during working of the Gantry type H Beam Submerged Arc Welding Machine;

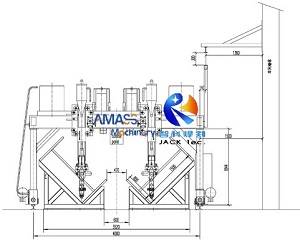

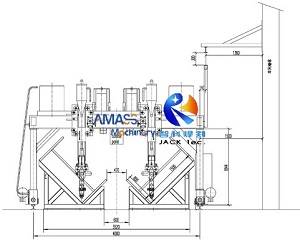

3) Mechanical welding unit --- Two sets of welding torch and its attachment: (Fig.4)

4) SAW Welding Power Supply --- Two sets, either Chinese brand HuaYuan(ZD7-1000) or U.S. Lincoln(DC-1000) has stable and solid quality: (Fig.5)

5) Wire feeder --- Two sets, for feeding welding wire during SAW of the Gantry type H Beam Welding Machine;

6) Flux Recovery unit --- Two sets, for welding flux recycling;

7) Arc Tracing unit --- Two sets, please see the sixth photo, for welding arc guide and torch adjustment during SAW of the Gantry type I Beam Welding Machine: (Fig.6)

8) Control System---Includes Control board, operating panel, control elements;

9) Piping System--- Power supply cable of Gantry type H Beam Welding Machine, control cable, air source tube, control cable of gantry, wire hanging sliding rack, welding cable, etc.

10) Spare parts --- Include three pieces of pushbuttons, three pieces of 6A and 4A RL8B-32fuse each, two pieces of 10A fuse (Spare parts may varies on specific model and customer demand) on the H Beam Gantry Welding Machine.

4. Technical Parameters of LHA5Z Gantry type H Beam Welding Machine:

Below are specifications of this LHA5Z center control high quality gantry type I Beam welding machine:

LHA5Z H Beam Gantry Welding Machine |

Parameter | Specification | Note |

Operator Working Position | Center of Gantry, between 2 supporting racks |

H Beam Flange Width (mm) | 200 ~ 800 |

|

H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

H Beam Web Height (mm) | 200 ~ 1800 |

|

H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

H Beam Length (mm) | 4000 ~ 15000 |

|

Gantry Span (mm) | 5000 |

|

Gantry Travel Rail Length (mm) | 18000 |

|