A. Traditional Welding H Beam Production Line:

1. Produces T H Beam in highly automatic streamline flow way, which presents large volume of finished steel structure workpieces in controllable and expected manner. This is the reason why this automatic machine group get widespread application for over two decades;

2. Primary Steps of Process Technology in I H Beam Production Line:

1) Assembly with CO2 gas shielded welding: H Beam Assembly Machine;

2) Submerged arc welding: H Beam SAW Welding Machine;

3) Flange straightening: H Beam Straightening Machine;

4) Transferring WIP (Work in process) workpieces among the above 3 stations: Steel Structure Flipping Equipment;

3. The total throughput time of H Beam production from loading onto line to unloading off line is fairly long;

4. Besides, installation on H Beam Production Line involves large area of workshop, from at least 2,400 m2 (100m length by 24m span) to ideal level of 4,800 m2 (200m length by 24m span), greatly deters many Steel Structure customers, who plan to invest on H Beam Production Line;

Wuxi JACK Exported to Russia automatic welding H Beam Production Line: (Fig.7)

![Fig7 Welding H Beam Production Line 6 DSC_0383 Fig7 Welding H Beam Production Line 6 DSC_0383]()

The above analysis gives reason on impetus driving Wuxi JACK developing 3 in 1 H Beam Welding Machine for customers.

B. Work Principle and Occupied Area of 3 in 1 H Beam Welding Machine:

1. The question is, for producing small and medium sized I H Beam, is it possible to integrate 3 steps of assembly / welding/ straightening into 1 time operation, and hence eliminate internal material transfer?

2. The answer is YES. This is the core idea behind development of 3 in 1 H Beam Welding and Straightening Machine, which plainly indicate its operating theory:

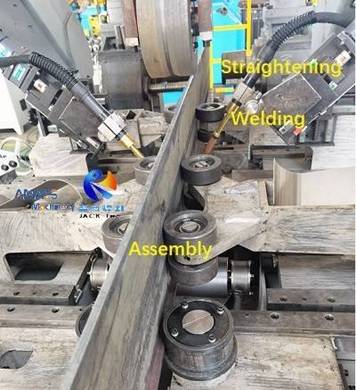

Central working area of Wuxi JACK 3 in 1 H Beam Welder Machine, from bottom to top in the photo: Assembly, Welding, Straightening: (Fig.8)

![Fig8 3 in 1 H Beam Welding Machine 191 Fig8 3 in 1 H Beam Welding Machine 191]()

3. Operation Nature: So, we can imagine that, in graphical view, application of 3 in 1 H Beam Welding Machine equals to compressing a production line into an individual point;

4. Correspondingly, the necessary land area in facility for installing 3 in 1 H Beam Welding Machine is only 100 ~ 104 m2 (24m length by 4m width), decreased from the least level of 2,400 m2 for welding H Beam Production Line, greatly reduces financial burden of Steel Structure customers for initiating on H Beam production.

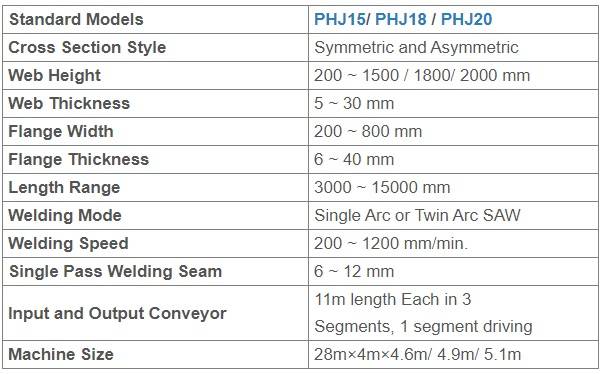

C. Put into Use on 3 in 1 H Beam Welding and Straightening Machine:

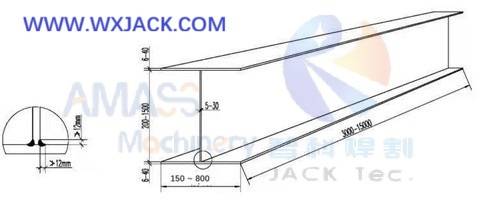

1. Finished Workpiece: This 3 in 1 H Beam Welder has unparalleled advantages for producing small and medium sized T I H Beam in upright position, with web height from 150mm to 2000mm, plate thickness from 4mm to 40mm:

Sketch on H Beam welded from 3 in 1 H Beam Welder Machine: (Fig.9)

![Fig9 3 in 1 H Beam Welding Machine 0C Fig9 3 in 1 H Beam Welding Machine 0C]()

2. The 3 Core Functions of 3 in 1 H Beam Welding Machine:

1) Assembly: To precisely fit up cut plates into T Beam and then H Beam in sequence;

2) Welding:

a) Majority with 1000A SAW welding, mainly from 380A to 750A working current, for welding medium T H Beam: 8- 40mm thickness;

b) Minority with 500A CO2 GMAW gas shielded welding, for welding small T H Beam: 4- 8mm thickness;

3) Straightening: Flattens out deformed H Beam flange after SAW welding;

The above 3 central functions are implemented exactly simultaneously in a row in the machine;

3. Machine Nomination: One machine can finish the entire task of T H Beam production. This is the origin of its name “3 in 1 H Beam Welding Machine” come from;

T Beam and H Beam produced from Wuxi JACK 3 in 1 H Beam Welder machine: (Fig.10)

![Fig10 3 in 1 H Beam Welding Machine 12 2 Fig10 3 in 1 H Beam Welding Machine 12 2]()

4. Values Added from 3 in 1 H Beam Welding and Straightening Machine:

Cost effectiveness and high standard performance of machine, which helps customer acquiring ideal revenue with substantially decreasing investment and daily manufacturing cost on H Beam production:

1) Period Cost Decrease with 3 in 1 H Beam Welding Machine:

Save over 50% machine investment budget, compared with purchasing the 4 original equipment in H Beam Production Line:

a) H Beam Assembly Machine;

b) H Beam SAW Welding Machine;

c) H Beam Straightening Machine;

d) H Beam Overturning Machine;

To now single set of equipment 3 in 1 H Beam Welder;

Reduce 80% workshop land occupation;

2) Variable Cost Decrease:

a) From traditional 6 operators to now 1- 2 operators;

b) Diminish over 50% utility consumption (Electricity + hydraulic oil + gas + water);

c) High Efficiency Value Stream Created: Raise 60%~ 70% productivity, by decreasing 60% Cycle Time, and removing material transfer time among work stations;

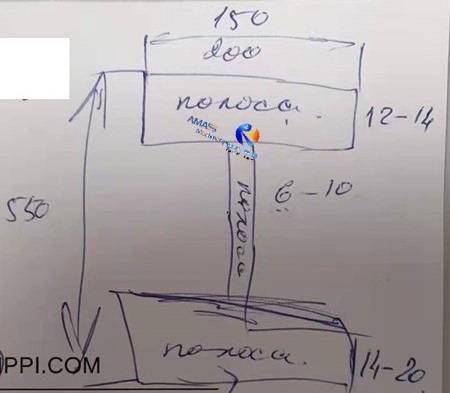

5. From T Beam to I H Beam, General Way of Operation in 3 in 1 H Beam Welding Machine:

Below photo shows beginning the second round operation for producing H Beam:

1) At the completion of T Beam welding, the T Beam is taken off outfeed conveyor, and hoist onto infeed conveyor;

2) The second piece of flange is hoisted onto infeed roller table also, and assembled with the T Beam, fit it into the final structure of H Beam;

From T Beam to I H Beam with 3 in 1 H Beam Welding Machine: (Fig.11)

![Fig11 3 in 1 H Beam Welding Machine 39 Fig11 3 in 1 H Beam Welding Machine 39]()

3) Then, repeat the steps finished in its first round of T Beam fabrication:

a) Being clamped and positioned with alignment rollers;

b) Being fabricated with SAW welding;

c) H Beam flange is straightened after welding;

d) With these steps, a piece of H Beam is finished fabrication:

e) First, T Beam: (Fig.12)

![Fig12 3 in 1 H Beam Welding Machine 36 Fig12 3 in 1 H Beam Welding Machine 36]()

f) Second, H Beam: (Fig.13)

![Fig13 3 in 1 H Beam Welding Machine 37 Fig13 3 in 1 H Beam Welding Machine 37]()

6. 3 in 1 H Beam Welding and Straightening Machine Operate for T Beam Fabrication:

1) T Beam is another important steel structure workpiece, not only as semi-finished workpiece of H Beam;

2) From the above steps we can see that, this machine can also be used into T Beam production. When work solely for T Beam production, machine application field is more seen in Shipbuilding industry than Steel Structure;

3) Accordingly, CO2 GMAW welding is more frequent use than SAW, because of higher IK value and hence welding seam strength acquired:

Fabricating T Beam with 3 in 1 H Beam Welder Machine: (Fig.14)

![Fig14 3 in 1 H Beam Welding Machine 163 CIMG2671 Fig14 3 in 1 H Beam Welding Machine 163 CIMG2671]()