A. Usage of 3 in 1 I H Beam Assembly Welding Straightening Integral Machine:

1. Other Frequently Used Names of 3 in 1 I H Beam Fabrication Machine:

1) Pull through H Beam welder;

2) Vertical H Beam welder;

3) Fit Up Full H Beam 3 in 1 machine;

4) Integral function H Beam 3 in 1 machine;

1) Function: This is new generation automatic welding H Beam production machine, with advanced technique and user friendly operation;

2) Output: This 3 in 1 machine produces welded T/ I / H Beams with web height from 200mm to 2,000mm, welding toe from 6mm to 12mm, the basic working parts applied in Steel Structure construction projects;

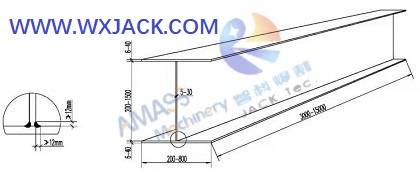

3) Design sketch on welded I/ H Beam to be produced: (Fig.1)

![Fig1 3 in 1 H Beam Fabrication Machine 182 Fig1 3 in 1 H Beam Fabrication Machine 182]()

4) Welded T/ H Beams produced from Wuxi JACK ZHJ15 model 3 in 1 I H Beam Welding Machine: (Fig.2,3)

![Fig2 3 in 1 H Beam Assembly Weld Straighten Integral Machine 36 Fig2 3 in 1 H Beam Assembly Weld Straighten Integral Machine 36]()

B. Advantages of Wuxi JACK 3 in 1 I H Beam Fabrication Machine:

1. One Machine Equals Three with 3 in 1 I H Beam Assembly Weld Straighten Integral Machine:

This 3 in 1 machine integrates functions of original 3 central machines in H Beam Production Line:

1) H Beam Assembly and Tack Welding Machine;

2) H Beam Submerged Arc Welding Machine;

3) H Beam Flange Straightening Machine;

Into single set of equipment;

2. Huge Financial Benefits of 3 in 1 I H Beam Fabrication Machine:

In this way, in the field of light to medium duty welding T/ I / H Beam manufacture, 3 in 1 I H Beam Fabrication Machine can greatly save budget for customers in quantitative data:

1) Over 50% machine investment;

2) Over 60% land and utility period cost;

3) Over 60% manual labor;

4) Over 60% variable cost of daily operation, including electricity/ maintenance/ consumables, etc.;

5) Remove internal logistics unit among the original 3 sets of the machines;

A piece of H Beam in vertical position just being finished production, from Wuxi JACK ZHJ15 model 3 in 1 H Beam Welding Machine: (Fig.4)

![Fig4 3 in 1 H Beam Assembly Welding Straightening Integral Machine 30 Fig4 3 in 1 H Beam Assembly Welding Straightening Integral Machine 30]()

C. Competitive Edges of Wuxi JACK 3 in 1 I H Beam Welding Machine:

1) The Earliest Development: PHJ and ZHJ series 3 in 1 H Beam machine is superior product of our company. In 2009, Wuxi JACK is the 1st company in industry to upgrade the machine from concept design to practical use, and put into market;

2) Top Grade Technique: 3 in 1 I H Beam Fabrication Machine developed by Wuxi JACK has overall technical superiorities compared with other supplier’s products, covering the 3 central functions of assembly/ welding/ straightening;

3) Leading Market Share: Over the past 2 decades, Wuxi JACK powerful 3 in 1 machine is widely welcomed by customers both in China and overseas, especially Russia, Central Asia, Southeast Asia, South America.

D. Classification on Wuxi JACK 3 in 1 I H Beam Assembly Weld Straighten Integral Machine:

1. Two Series of 3 in 1 I H Beam Fabrication Machine:

PHJ series and ZHJ series:

1) Which differs on H Beam flange and web fitting up manner, and hence cross section style of finished T/ I / H Beam;

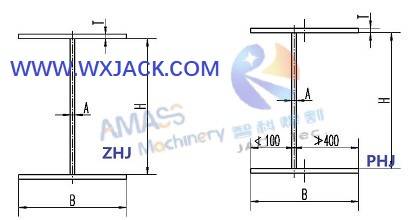

2) Difference of H Beam cross section to be produced from PHJ and ZHJ models machine: (Fig.5)

![Fig4 Integral Function H Beam Welding Machine 30 Fig4 Integral Function H Beam Welding Machine 30]()

2. ZHJ Series 3 in 1 I H Beam Fabrication Machine:

1) Focuses on producing symmetric cross section welding T/ I/ H Beam;

2) A set of Wuxi JACK ZHJ15 model 3 in 1 I H Beam Fabrication Machine fabricates vertical equal lateral length H Beam: (Fig.6)

![Fig5 H Beam Steel Structure Production Line 7 Fig5 H Beam Steel Structure Production Line 7]()

3. PHJ Series 3 in 1 I H Beam Welding Machine:

As shown in Fig4., PHJ series machine manufactures welded T/ I / H Beam with both equal and unequal length flange.

E. Technical Characteristics of Wuxi JACK 3 in 1 I H Beam Fabrication Machine:

1. Assembly Unit in 3 in 1 I H Beam Welding Machine:

1) PHJ series works in semi-automatic mode: One side of workpiece is driven with hydraulic oil cylinder, and the other side is adjusted manually with handwheel turning;

2) ZHJ series works in automatic mode, both sides fitting up are driven with hydraulic oil cylinder;

3) Both PHJ and ZHJ machine assembling positioning are guided with precise bushing, aligned with eccentric roller, guaranteeing accurate fitting up flanges with web;

4) High stability and reliable working assembly pressing rollers of Wuxi JACK H Beam 3 in 1 machine: (Fig.7)

![Fig5 3 in 1 H Beam Assembly Weld Straighten Integral Machine 14 Fig5 3 in 1 H Beam Assembly Weld Straighten Integral Machine 14]()

2. Welding Unit of 3 in 1 I H Beam Welding Machine:

1) SAW (Submerged arc welding) takes majority welding job, fabricating 6mm ~ 40mm flange thickness;

2) CO2 Welding: This is featured configuration of Wuxi JACK machine, for fabricating on super light T/ I/ H Beams, with flange thickness 3mm ~ 12mm;

3) Unique design on high precise welding torch position control unit, in Wuxi JACK 3 in 1 I H Beam Assembly Weld Straighten Integral Machine: (Fig.8)

![Fig6 3 in 1 H Beam Welding Machine 150 IMG_1561 Fig6 3 in 1 H Beam Welding Machine 150 IMG_1561]()

3. Straightening Unit in 3 in 1 H Beam Assembly Welding Straightening Integral Machine:

1) Super Powerful Straightening Capacity: Wuxi JACK machine has 2 times straightening capacity than that of other suppliers:

2) To be specific, Wuxi JACK max. straightening capability is 40mm flange thickness for Q235 carbon steel (Tensile strength 370~ 510 MPa), or 30mm flange thickness for Q345 carbon steel (Tensile strength 510 ~ 600 MPa);

3) Other supplier max. straightening capability is only 20mm flange thickness for Q235 carbon steel. Can not straighten Q345 carbon steel;

4) Powerful Straightening unit in Wuxi JACK 3 in 1 I H Beam Assembly Welding Straightening Integral Machine: (Fig.9)

![Fig7 3 in 1 H Beam Assembly Welding Straightening Integral Machine 161 Fig7 3 in 1 H Beam Assembly Welding Straightening Integral Machine 161]()

F. Technical Parameters of Wuxi JACK 3 in I H Beam Welding Machine:

1) Below are parameters of standard models PHJ and ZHJ series H Beam 3 in 1 machine;

2) We also design and produce special specifications based on customer requirement.

| 3 in 1 I H Beam Assembly Welding Straightening Integral Machine (3 in 1 I H Beam Fabrication Machine)

|

Technical Parameter | PHJ15 | PHJ18 | PHJ20 | ZHJ15 | ZHJ18 | ZHJ20 |

Web Height | 200∼ 1500 mm | 200∼ 1800 mm | 200∼ 2000 mm | 200∼ 1500 mm | 200∼ 1800 mm | 200∼2000 mm |

Web Thickness | 5∼ 30 mm | 6∼ 32 mm |

Flange Width | 200∼ 800 mm | 150∼ 750 mm |

Flange Thickness | 6∼ 40 mm |

Single Pass Welding Seam Height | 8~ 12 mm |

Workpiece Length | 3000∼ 15000 mm |

Welding Speed (Assembly, Straighten same) | 200∼ 1200 mm/min.(VFD) |

Machine Size(L×W×H) | 28m×4m×4.6m | 28m×4m×4.9m | 28m×4m×5.1m | 28m×4m×4.2m | 28m×4m×4.5m | 28m×4m×4.8m |