A. Usage and Application of RH Series H Beam and Plate Edge Rounding Machine:

1. Function of End Plate Trimming Machine:

1) RH series H Beam and Plate Edge Rounding and Deburring Machine is for carrying out rounding and trimming on the 4 edges of steel workpieces/ Plates/ H Beam, into fillet smooth angles of radius Φ2~ Φ2.5mm;

2) A piece of 300mm width strip plate is being rounded in Wuxi JACK RH1000 model machine: (Fig.1)

![Fig1 Plate Edge Rounding Machine 11 IMG_6479 Fig1 Plate Edge Rounding Machine 11 IMG_6479]()

2. The Necessity of Using Plate Edge Deburring and Rounding Machine:

1) Generally speaking, the 3 major usage of edge rounding are:

a) Raising Painting Property: Enhance surface painting adhesion of steel plates;

b) Improve stress concentration of workpieces;

c) Removing burrs and dirt on corner and surface of sheet metal;

In a nutshell, greatly improves mechanical property of steel plate, before next process technology steps of fabrication/ assembly/ painting;

3. Application of Sheet Metal and H Beam Edge Rounding Machine:

1) In this way, for those finished machineries and constructions/ buildings which will operate in surroundings with great moisture, let alone directly in water such as ship, the edge rounding operation can bring along the best performance on resisting negative effect of humid environment (Moisture/ water/ steam...), guaranteeing on durable operation of the machines and utilities;

2) Clients: So, Edge Rounding Machine is very useful for manufacturers of Shipbuilding/ Port Machinery/ Bridge Construction/ Cranes and Hoist Machinery, etc.;

3) The other name of the machine: When being applied for machining on sheet metal steel plate, this machine sometimes is also named as End Plate Trimming Machine;

4. Applicable Working Parts of Steel Plate and H Beam Edge Rounding and Deburring Machine:

1) Steel Plate: Majority of RH models machines are used for working on sheet metal steel plate, especially steel plate, of either small width (150mm ~ 1,000mm), or larger width (Up to 3,000mm):

A piece of 3,000mm width wide plate is being edge rounded and trimmed from Wuxi JACK RH3000 model machine: (Fig.2)

![Fig2 Plate Edge Rounding Machine 22 Fig2 Plate Edge Rounding Machine 22]()

2) H Beam: Besides, H Beam is also a frequently applied workpiece on edge rounding:

3) Close up view on H Beam being trimmed in Wuxi JACK HR800 model machine: (Fig.3)

![Fig3 H Beam Edge Rounding Machine 2 Fig3 H Beam Edge Rounding Machine 2]()

5. Working Nature: RH series machine is a kind of pre-processing 1st operation equipment on raw materials, before the next manufacturing step of welding or painting.

B. Work Stations of RH Series Plate Edge Rounding and Deburring Machine:

1. Where does End Plate Trimming Machine being Applied?

1) BOL (Begin of Line): This machine is usually deployed at beginning stations of large machinery production line, in the field of Shipbuilding/ Port Machinery/ Bridge Construction, etc.:

2) In sequence, the subsequent work stations of edge rounding are: Fabrication (Welding), assembly, and painting;

3) For Steel Plate: Wuxi JACK RH3000 model machine on wide plate, being deployed in a Chinese Port Machinery production line: (Fig.4)

![Fig4 Plate Edge Rounding Machine 24 Fig4 Plate Edge Rounding Machine 24]()

2. Work station of HR800 model on H Beam edge rounding, in H Beam steel structure production line: (Fig.5)

![Fig5 H Beam Edge Rounding Machine 4 Fig5 H Beam Edge Rounding Machine 4]()

3. Related Equipment with Plate and H Beam Edge Deburring and Rounding Machine:

1) Steel Plate Edge Machining: Both these RH models machines and XBJ series Edge Milling Machine are used for machining on edges of steel plate, making prepare for the next step of process technology: Either painting or welding;

2) On the other hand, These 2 types plate machining machines have different finished effect on steel plates, for serving on different application purposes:

3) Finished trimmed and rounded steel plate from Wuxi JACK RH1000 model machine: (Fig.6)

![Fig6 End Plate Trimming Machine 17 Fig6 End Plate Trimming Machine 17]()

4) H Beam Edge Trimming: H Beam Edge Rounding Machine versus HYJ/ YTJ series H Beam Straightening Machine, which is used for flattening on deformed H Beam flange after SAW (Submerged arc) welding;

4. In a nut shell, RH series machine on edge rounding is a powerful and indispensable 1st operation equipment, in the field of producing diversified finished plate and steel structure parts.

C. Work Principle of RH Series H Beam and End Plate Trimming Machine:

1. Operating Theory in Edge Rounding Machine:

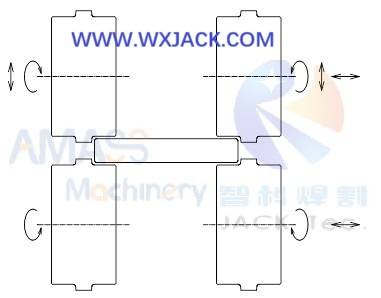

1) This can be intuitively viewed from below design sketch: (Fig.7)

![Fig7 Edge Rounding and Deburring Machine 18 Fig7 Edge Rounding and Deburring Machine 18]()

2) Edge Rounding Unit: There are 4 pieces of edge rounding rollers, which form into a square shape working cavity. And, with workpiece (Plate/ H Beam) going through this cavity, the 4 corners of workpiece will be rounded and trimmed, under the power action and squeeze force of the 4 rollers;

3) Edge rounding rollers are execution element of machines. It is made of 35CrMo tool steel, precisely machined, and heat treated to have stress relieved. In this way, the edge rounding rollers have stable and high persistent performance, promising long service life that can be tracked on:

4) Edge rounding rollers of Wuxi JACK RH models H Beam and plate Edge Rounding Machine: (Fig.8)

![Fig8 Edge Rounding Machine 20 Fig8 Edge Rounding Machine 20]()

2. Drive on Edge Rounding Operation:

1) The squeeze on corners of steel plate/ H Beam entails heavy and reliable force, which should be provided with hydraulic oil cylinders;

2) Summing up, operating site of Wuxi JACK RH3000 model on large plate, works at Port Machinery customer running site: (Fig.9)

![Fig9 Edge Rounding and Deburring Machine 25 IMG_20210911_154625 Fig9 Edge Rounding and Deburring Machine 25 IMG_20210911_154625]()

D. Classification on Wuxi JACK RH Series H Beam and Plate Edge Deburring and Rounding Machine:

Below is outline:

1. Varied Width Plate Edge Rounding Machine:

Depending on the max. width of steel plate:

1) RH800 ~ RH1000 models, for acquiring on end trimming on strip plate with max. width of 800mm to 1000mm:

Wuxi JACK RH1000 model on narrow plate edge rounding: (Fig.10)

![Fig10 Narrow Plate Edge Rounding Machine 11 IMG_6472 Fig10 Narrow Plate Edge Rounding Machine 11 IMG_6472]()

2) RH1500 ~ RH3000 models, for implementing on edge processing on steel plate with the max. width from 1,500mm to 3,000mm;

Customer has acceptance on Wuxi JACK RH3000 model machine on wide sheet metal: (Fig.11)

![Fig11 Edge Deburring and Rounding Machine 10 IMG_3299 Fig11 Edge Deburring and Rounding Machine 10 IMG_3299]()

As can be observed from the 2 photos, the 2 types of machine model on narrow and wide plate have different structures and working manner;

2. HR800 model H Beam Edge Rounding Machine, at EOL (End of line) station of H Beam Production Line: (Fig.12)

![Fig12 H Beam Flange Edge Deburring and Rounding Machine 7 Fig12 H Beam Flange Edge Deburring and Rounding Machine 7]()

E. Content of Product Family RH series H Beam and Plate Edge Rounding Machine:

1. Customer Interest on Topics of: You may have interest on topics of RH series machine: Its Usage and value/ Working principle/ Structure/ Installation and commissioning/ Operation and regular service/ Main units / Manufacture technology/ Performance … etc. Which we will have introduction in related models of products;

2. Tailor Made Models: Like all the other products of Wuxi JACK machinery and equipment, for RH series machine, we also have rich experience and superior technical strength on designing and producing tailor made models, based on specific demand from customers;

3. Technical Parameters: Every model of product section has specific and detailed introduction on and technical parameters.