Here we take Wuxi JACK ASM63 model machine as an example to explain:

1. The Way of Angle Iron Straightening Machine Straightening on Angle Steels:

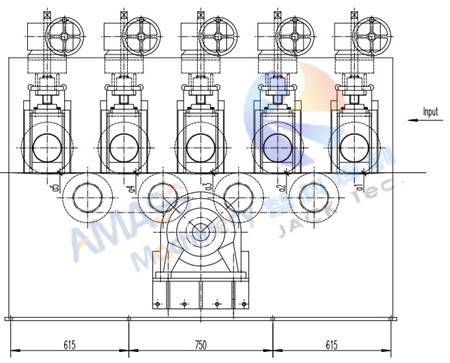

1) Straightening Rollers Quantity and Arrangement: As shown in the above 1st photo, there are 5 pieces of downward acting straightening rollers, and 4 pieces of bottom assembled stationary straightening rollers, in a set of Wuxi JACK ASM series Angle Steel Straightener Machine;

2) Workpiece Going Through Way: The working parts Angle Steel come into mechanical main frame of the machine, either from its righthand or lefthand side. Shown in below:

In below design sketch, Angle steel goes into the machine for being straightened, moving in the direction of from right side to left side: (Fig.1)

![Fig1 Angle Steel Straightening Machine Fig1 Angle Steel Straightening Machine]()

3) Rule of Thumb on Critical Process Parameters:

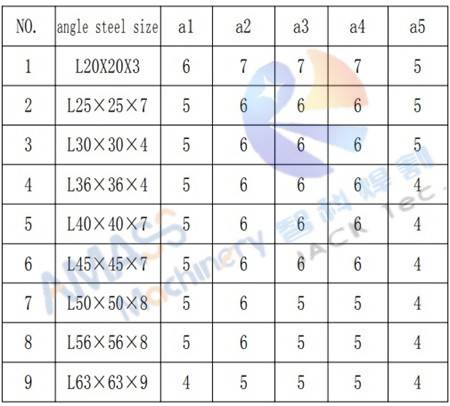

a) Wuxi JACK has rich accumulation of empirical data, on suggested downward stroke of each piece of the 5 downward acting straightening rollers, for straightening on each specification of Angle steel. This is very valuable data for customer, and can help customer acquiring on satisfactory operation performance of the Angle Iron Straightening Machine. For example:

b) Empirical data chart of Wuxi JACK ASM63 model Rolled Angle Straightening Machine, for downward moving stroke of each piece of straightening roller, for each specification of Angle Steel: (Fig.2)

![Fig2 Angle Steel Straightening Machine Fig2 Angle Steel Straightening Machine]()

4) Fulfil Satisfactory Straightening Effect: You can find that with the Angle Steel going forward through central working unit of our Angle Steel Straightener Machine, it gradually grows flattened. The straightening target on Angle Steel can be attained automatically and effectively.

2. Make Adjustment on Downward Acting Stroke of Straightening Rollers in Angle Steel Straightener Machine:

1) Drive and Transmission on Downward Straightening:

a) As shown in the above 2nd photo, the downward movement of straightening rollers are transmitted with worm gear reducer, which are installed at top of mechanical main frame of the machine:

b) Vertical view on worm gear reducers installed on central function cell of Wuxi JACK Angle Steel Straightening Machine: (Fig.3)

![Fig3 Steel Angle Straightening Machine 9 Fig3 Steel Angle Straightening Machine 9]()

2) Drive Force Source on Straightening Rollers Downward Movement:

This is the most important force for Angle Steel straightening operation:

a) For light to medium models ASM63/ 100/ 130, the power on turning worm gear reducers is realized with manual turning handwheels by operator;

b) For large heavy duty models ASM160/ 200, the power on turning worm gear reducers is driven with A.C. motors and reducers --- Manual turning can not attain on such job.

3. Precise Control on Straightening Rollers Downward Moving Stroke in Rolled Angle Straightening Machine:

1) Significance and Function: Downward stroke of straightening rollers determine on straightening effect and efficiency on Angle Steel, which can be observed by operator conveniently:

2) As shown in the above 3rd photo, being pasted onto front wall of machine main frame, alongside each piece of the downward moving straightening roller, there is a piece of indicating ruler indicating on downward stroke:

Indicating ruler on downward moving stroke of straightening roller: (Fig.4)

![Fig4 Rolled Angle Straightening Machine 8 Fig4 Rolled Angle Straightening Machine 8]()

3) Operation: Before straightening operation, operator can check on actual downward stroke of each of the straightening roller with this ruler, and make adjustment accordingly if necessary.

4. Central Working Unit of Angle Steel Straightening Machine:

1) Finally, as shown in the above 4th photo, the straightening operation on workpiece Angle Steels is implemented in working cell, which is right inside mechanical main frame of the machine;

2) Side view on central operating unit, straightening and conveying Angle Steel out of the machine: (Fig.5)

![Fig5 Angle Steel Straightening Machine 17 Fig5 Angle Steel Straightening Machine 17]()