- Home

- Products

- H Beam Assembly Weld Straighten Integral Machine

- H Beam End Face Milling Machine

- Plate Beveling Machine

- Plate Butt Joining Machine

- CNC Strip Plate Cutting Machine

- BOX Beam Production Line

- H Beam I Beam Weld Production Line

- Pipe Tank Vessel Rotator Turning Roll

- CNC Pipe Cutting Machine

- Positioner

- Pipe Tank Vessel Welding Manipulator

- Special Purpose Welding Equipment

- Angle Steel Straightening Machine

- T Beam Production equipment

- Pipe Assembly and Welding machine

- H Beam I Beam BOX Beam Steel Structure Member Flipping Equipment

- H Beam Production

- H Beam Fabrication Machine

- Integrated Function H Beam Welding Machine

- H Beam Assembly Welding Straightening Integral Machine

- Quick Understanding on Wuxi JACK H Beam Fabrication Machine

- Three in One H Beam Welding Machine

- H Beam Production Line

- Automatic and Manual H Beam Production Line

- Slides on Wuxi JACK H Beam Production Line

- Equipment in H Beam Production Line

- H Beam Assembly Machine

- Technical View on Wuxi JACK H Beam Assembly Machine

- H Beam Welding Machine

- Open Structure H Beam Welding Machine

- Wuxi JACK H Beam Gantry Welding Machine Slides

- SAW H Beam Gantry Welding Machine

- H Beam Straightening Machine

- H Beam Flange Straightening Machine

- Review on Wuxi JACK H Beam Straightening Machine

- Beam Longitudinal Straightening Machine

- Plate Process

- Edge Milling Machine

- General Purpose Edge Milling Machine

- Double Heads Long Stroke Edge Milling Machine

- Advanced Configuration Edge Milling Machine

- Advantages of Wuxi JACK Edge Milling Machine

- Wuxi JACK Hobbing Cutter

- Plate Butt Joint Welding Machine

- Flat Butt Welding Machine

- The Powerful Wuxi JACK Plate Butt Joint Welding Machine

- Edge Rounding Machine

- Wuxi JACK Plate Edge Rounding Machine

- Wide Plate Edge Rounding Machine

- Narrow Strip Edge Rounding Machine

- Steel Structure

- Beam End Face Milling Machine

- Wuxi JACK Beam End Face Milling Machine Advantage

- Standard Models Beam End Face Milling Machine

- Special Size Beam End Face Milling Machine

- Use Wuxi JACK Steel Structure Beam End Face Milling Machine

- Angle Steel Straightening Machine

- Outline on Wuxi JACK Angle Steel Straightening Machine

- BOX Beam Production Line

- Brief Review on Wuxi JACK BOX Beam Production Line

- T Beam Production Line

- Notes on Wuxi JACK T Beam Production Line

- Steel Structure Overturning Equipment

- Summary on Wuxi JACK Steel Structure Overturning Equipment

- Steel Structure Chain Manipulator

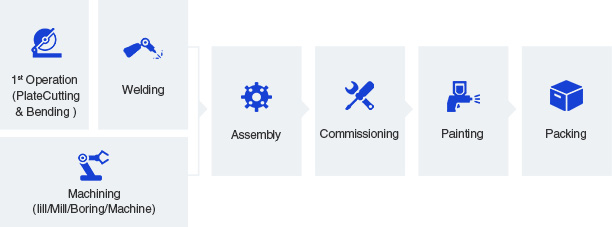

- Wuxi JACK Steel Structure Machine and Production Line

- Wuxi JACK Steel Structure Straightening Machine

- Stiffened Plate Straightening Machine

- Wuxi JACK Ribbed Plate Element Straightening Machine

- Pipe Assembly and Welding Machine

- Automatic Welding

- Welding Positioner

- Two Axis Welding Positioner

- Superiority of Wuxi JACK Welding Positioner

- Three Control Axis Welding Positioner

- Single Working Axis Rotary Welding Table

- Head and Tail Welding Positioner

- Special Made Welding Positioner

- Servo Drive Welding Positioner

- Welding Fixture

- Welding Equipment

- Brief on Wuxi JACK Pipe Welding Machine

- Pipe Welding Machine

- Welding Manipulator

- Welding Column and Boom

- Introduction on Wuxi JACK Welding Column and Boom

- Welding Center

- Gathering of Wuxi JACK Welding Machine

- Welding Rotator

- Conventional Standard Welding Rotator

- Summary on Wuxi JACK Welding Rotator

- Special Made Welding Rotator

- Welding Rotator in Use

- Tailor Made Welding Rotator

- CNC Machine

- CNC Pipe Cutting Machine

- CNC Pipe Intersection Cutting Machine

- Advanced Wuxi JACK CNC Pipe Cutting Machine

- CNC Control Pipe Beam End Face Milling Machine

- CNC Strip Plate Cutting Machine

- CNC Flame Plate Cutting Machine

- CNC Plasma Plate Cutting Machine

- CNC Drilling and Cutting Machine

- Complex of CNC Cutting Machine

- Overview on Wuxi JACK CNC Plate Cutting Machine

- One Page Summary on Wuxi JACK

- Wuxi JACK Welding Equipment and Machinery

- Wuxi JACK Cutting and Machining Equipment

- Wuxi JACK Straightening Machine

- Wuxi JACK Steel Structure Production Line

- Wuxi JACK Steel Structure Welding Machine

- Machine Tool Products Classification

- Video

- Working Video of Plate Butt Joint Welding Machine

- Working Video of CNC Pipe Cutting Machine

- Working Video of Beam End Face Milling Machine

- H Beam Fabrication Machine Working Video

- Video of H Beam Assembly Weld Straighten Integral Machine

- Video of Integral Function H Beam Welding Machine

- Video of Three in One H Beam Welding Machine

- Working Video of Edge Milling Machine

- General Purpose Edge Milling Machine Working Video

- Operating Video of Double Heads Edge Milling Machine

- Video of Advanced Function Plate Edge Milling Machine

- Video of Wuxi JACK Standard and Special Made End Milling Machine

- Contact