A. Usage and Application of Sheet Metal Plate Edge Milling Machine:

1. Function: XBJ series Edge Milling Machine is 1st operation general purpose machining equipment, cutting out high precision glossy welding grooves on edges of workpieces, by means of high speed revolution of milling head facer blade along machine worktable;

2. Types of Welding Grooves Cut from Edge Beveling Machine:

This can be:

1) Straight edge as basic machining on sheet metal;

2) 0° ~ 45° or wider angle scope (60°/ 85°) of up edge beveling;

3) -45° ~ 0° on lower edge beveling:

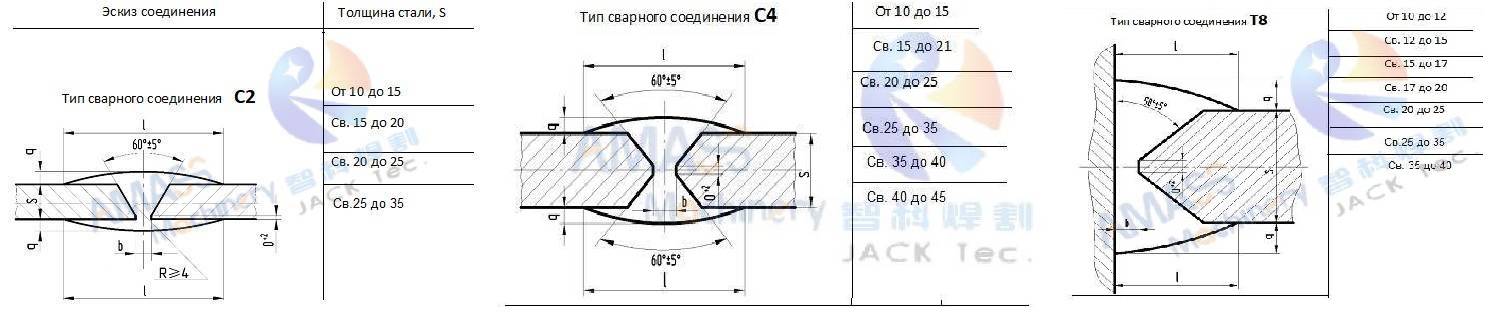

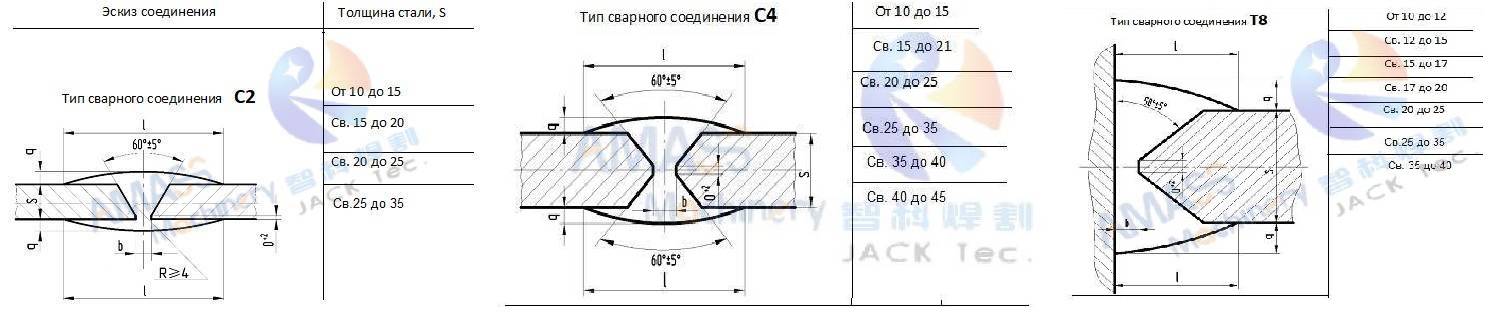

a) V/ X/ K grooves milled from Wuxi JACK Plate Beveling Machine: (Fig.1)

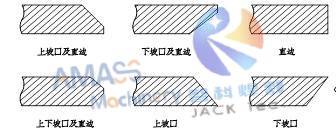

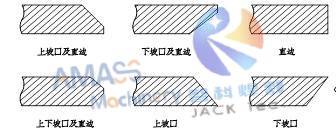

b) The 6 common seen types of welding grooves machined from Edge Milling Machine: (Fig.2)

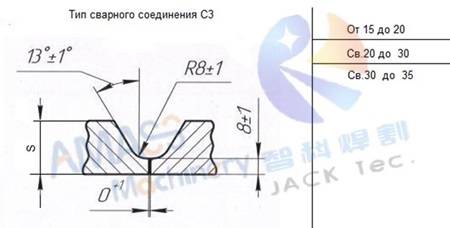

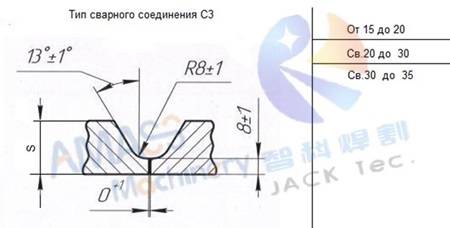

c) Equipped with special circular cutter, the Edge Milling Machine can also cut our U shape welding groove: (Fig.3)

3. Material of workpieces in Edge Beveling Machine: Carbon Steel /Stainless Steel/ Bronze... The most majority in practical application is carbon steel plate;

4. Usage: Edge Milling Machine fulfils beveling or chamfering on edges of sheet metal plate, into the final U/ V / X chamfer, or straight edges, so that the subsequent welding operation on sheet metal can fabricate out welding seams of eligible welding fusion and cover face, acquiring ideal welding performance;

5. Finished Welding Chamfers Cut from Wuxi JACK Plate Beveling Machine:

1) Straight edge as basic necessary and first step milling: (Fig.4)

2) 40° upper edge bevel from single head Edge Milling Machine: (Fig.5)

3) Straight/ upper/ lower edges bevel (Half X groove) machined from double heads Edge Milling Machine: (Fig.6)

6. Extensive Application of Sheet Metal Steel Plate Edge Milling Machine:

1) Across Industry: Nealy all manufacturing industries, wherever sheet metal plates are used as raw materials for production, especially with process technology step of steel plate welding, have the demand on Edge Milling Machine, covering industries of: Vehicles/ Bridge/ Construction Machinery/ Petrochemical/ Pressure Vessel/ Steel Structure, etc.;

2) Operation Form: Edge Beveling Machine can be used in the form of individual machining equipment, or works together with other machines, to be composed into various production line; Or working as double tandem sets working group;

3) For example, served as welding groove machining equipment, preceding Welding Manipulator, or Plate Butt Joint Welding Machine.

B. Major Specifications of Wuxi JACK Sheet Metal Plate Edge Beveling Machine:

1. Max. Plate Thickness: Conventional applicable thickness range of sheet metal is 6~ 50mm; Under special cases for customer demand, the max. thickness capacity of sheet plate can be up to 100mm or even 160mm;

2. Max. Plate Length: Usually length range of steel plate is from 3,000mm to 18,000mm for standard models Plate Beveling Machine, and being expanded into 20,000mm or even 23,000mm for special made four/ five milling heads models;

3. Max. Plate Width: The max. width is usually 3500mm ~ 4000mm;

4. Developing by Wuxi JACK, the Leading Chinese Supplier on Edge Milling Machine:

1) Design Idea: This XBJ series machine was developed under the background and ideology of “Plate Edge Milling Machine takes the position of Planar”: Maintaining the same level of superior welding groove milling performance, while greatly reduce manufacturing cost and purchase budget of machine;

2) Advantages of Edge Beveling Machine Compared with Planar Machine:

a) Higher efficiency on beveling;

b) More less energy consumption during beveling operation;

c) Much lower quotation and running cost of the machine;

In this way, maintaining the original good point of Planar Machine: High quality and precision.

C. Working Principle and Main Units of Wuxi JACK Sheet Metal Steel Plate Beveling Machine:

1. Put into Operation on Edge Milling Machine:

1) Operation Way: Utilizing milling head and facer blades, motor drive milling carriage moves under adjustable working velocity along edge of sheet metal plate, accomplishing task of high speed high precision edge milling:

Wuxi JACK XBJ-6 model Edge Beveling Machine mills on 45° up edge groove: (Fig.7)

2) Working Speed of edge milling can be adjusted continuously within the range of 100~ 1000mm/min., which is controlled by means of A.C. inverter, and real time displayed on operating pendant:

Operating pendant and edge milling speed show during beveling operation, in Wuxi JACK exported to Southeast Asia Plate Edge Milling Machine: (Fig.8)

2. Central Function Units of Wuxi JACK Plate Edge Beveling Machine:

1) Milling Head: As top grade Chinese Producer on Edge Milling Machine, Wuxi JACK selects milling head of 7.5 kW in conventional models, and 9 kW or 11 kW in heavy duty models:

7.5kW milling head in operation: (Fig.9)

2) Mechanical Main Frame: Including lengthways mechanical base bed/ work table (Machined and heat treated)/ gantry frame;

Assembled mechanical frame of Wuxi JACK exported to Europe SXBJ-125 large model Edge Milling Machine: (Fig.10)

3) Hydraulic System: Its role is to provide driving force to firmly clamp on workpiece (Steel plate) onto machine worktable, for guaranteeing on high level operation; When equipped with roller tables, acting as drive source on pushing and pulling steel plate into and out of Edge Milling Machine worktable, etc.;

4) Steel Plate Loading Roller Tables: This can be either conventional brackets for manual pushing and pulling plate, or Wuxi JACK exclusively owned hydraulic drive automatic handling groups:

Wuxi JACK uniquely supplied hydraulic drive steel plate handling roller tables, for Plate Edge Milling Machine: (Fig.11)

5) Electric control cabinet and operating system of machine, and each set of milling head motorized moving carriage.

D. Types of Models from Wuxi JACK, Top Chinese Supplier on Edge Milling Machine:

There are many perspectives dividing on the machine.

1. Based on Quantity of Milling Head in Plate Edge Beveling Machine:

1) XBJ series single head configuration;

2) SXBJ series double heads Plate Edge Milling Machine;

3) FXBJ&GFXBJ series four to five heads configuration heavy duty;

This group of machine is equipped with one or two sets of 7.5kW milling head, with milling length in the range of 3,000mm ~ 18,000mm (Models: XBJ/SXBJ-3 ~ XBJ/SXBJ-18);

On the basis of common seen functions and configuration, our strong strength is to design and introduce special structure/ functions and specifications of machine, meeting customer specific needs. For example:

1) Heavy duty four to five milling heads configuration;

2) Both sides of worktable simultaneously edge milling;

3) Splitting structure mechanical frame, for processing on super larger heavy steel plates of 70s+ tonnage weight;

4) Equipped with super power 11kW/ 18.5kW /55kW milling head;

5) HMI (Human machine interface) for precisely controlling on edge milling angle;

6) Equipped with Wuxi JACK uniquely configured hydraulic drive roller table;

7) Motor drive and encoder control tilting and feeding of milling head;

8) Ammeter of milling head to manage on milling cut depth, etc.

a) HMI in Wuxi JACK advanced configuration Edge Milling Machine:(Fig.12)

b) Ammeter on Taiwan E-LONG 9kW milling head, equipped in Wuxi JACK advanced configuration plate Edge Beveling Machine:(Fig.13)

E. Powerful Function and Leading Edge of Wuxi JACK, Top Grade Chinese Producer on Edge Milling Machine:

1. Superior Quality Function Units of Wuxi JACK Plate Edge Beveling Machine:

Design and manufacture on function units of Wuxi JACK Plate Beveling Machine, such as: Integral fender for small part, movable fender, guard on top and bottom guideway, hydraulic oil cylinder drive movement of workpiece... All take lead position in the industry, and some of these components are unique function units of Wuxi JACK Plate Edge Milling Machine:

1) High quality milling head, produced by professional supplier, installed in milling carriage of Wuxi JACK Sheet Metal Plate Edge Milling Machine: (Fig.14)

2) Electric control cabinet of motorized milling head carriage, installed with HMI touch screen in door of the electric cabinet: (Fig.15)

3) Superior facer blade installed milling head, of Wuxi JACK Sheet Metal Plate Edge Beveling Machine: (Fig.16)

4) High precision liner guiderail of Wuxi JACK Edge Milling Machine: (Fig.17)

2. Leading Market Share: This machine is one of the top sale products of our company. Wuxi JACK are leading Chinese Supplier on Edge Milling Machine in the market for over 2 decades. We have many customers in China and Overseas, and have gained high recognition from clients over the past 2 decades;

3. Design Strength: We are very good at design and produce any special models of machine based on customer demand.Many core functions of Wuxi JACK Edge Milling Machine take the lead in market. This lies at Wuxi JACK technical strength.