A. Usage of Angle Steel Profile Straightening Machine:

1. Function of Rolled Angle Steel Straightening Machine:

1) Wuxi JACK ASM series L Angle Steel Straightener Machine is for straightening on longitudinal deformation of Angle Steel (The other name of the raw material: Rolled Angle, Angle Bar, or L steel) along its lengthways direction, including warping/ bending/ hemming, etc.:

2) Wuxi JACK operator has trial run on ASM100 model machine during final assembly and test: (Fig.1)

![Fig1 L Angle Steel Profile Straightening Machine 10 Fig1 L Angle Steel Profile Straightening Machine 10]()

2. Models of Wuxi JACK L Angle Steel Straightener Machine:

1) Based on cross section size of the Angle Steel, this series of machine has several standard models to choose from, ASM63/ ASM100/ ASM130/ ASM130/ ASM200;

2) Denotation on Machine Model: Each model of the machine corresponds with the Max. side width of Angle Steel for straightening. For example, the Max. size of Angle steel in ASM130 model is 130 x 130 x 12mm. For detail, please check below workpiece specification table at the end of this product family;

a) Wuxi JACK ASM100 model machine ready for shipment: (Fig.2)

![Fig2 L Angle Steel Straightener Machine 6 IMG_4157 Fig2 L Angle Steel Straightener Machine 6 IMG_4157]()

b) Wuxi JACK ASM200 large model heavy duty machine after test and paint: (Fig.3)

![Fig3 Angle Steel Profile Straightening Machine 2 IMG_7203 Fig3 Angle Steel Profile Straightening Machine 2 IMG_7203]()

3. Special Design on Machine: Also, Wuxi JACK engineering team can design and produce ASM model Angle Iron Steel Straightening Machine of special size and hence special model, to meet the special requirement from customers;

4. Similar Steel Structure Framework Straightening Equipment: This ASM series L Angle Steel Straightening Machine has its workpiece straightening process related with another important and widely applied machinery: H Beam Flange Straightening Machine, but in different machine structure and working principle.

B. Advantage and Great Value of L Angle Steel Straightening Machine for Customer:

1. Wuxi JACK Featured Machine Tool of Rolled Angle Steel Straightening Machine:

1) The ASM series is featured product of Wuxi JACK, which was developed by our engineering team and put into market in the year of 2013;

2) Application Background of the Machine: As a kind of widely applied large consumption volume steel structure workpieces, Angle Steels are easy to have longitudinal deformation along its length direction body, which are caused from: Hoist/ Transportation/ Storage... And should be straightened accordingly, to carry out high standard next step of operation. Accordingly, there exist large market demand on this machine;

3) Trial run on Wuxi JACK ASM200 large model heavy duty machine, straightening on large Angle steel: (Fig.4)

![Fig4 L Angle Steel Straightening Machine 29 IMG_7081 Fig4 L Angle Steel Straightening Machine 29 IMG_7081]()

2. Straightening by Hands Before Angle Iron Steel Straightening Machine for Customers:

Before development of this ASM series L Angle Steel Straightener Machine, the Angles Steel straightening process was implemented manually, by operator hands. The negative points for customers can be listed as:

1) Unnecessary High Labor Cost: There involved many operators hard and toilful job, which has very low added value for such operation. For employer, variable cost on human labor is very high;

2) Unstable and Uncontrollable Straightening Performance: Besides, manual straightening by operator, has potential risk of inconsistent straightening quality, because of operator fatigue, in poor condition, etc.;

The introduction of this L Angle Steel Straightening Machine saves labor job immensely, and produces straightened L Angle steel with uniform quality;

3. With Bring into Use on Rolled Angle Steel Straightening Machine:

Comparatively, automatic machine brings along automatic operation on Angle steel straightening. The corresponding merits of this automation are:

1) Greatly Saving Labor Cost: With much less operator necessary for the operation, the payback period on investment on this machine can be less than 2 years, with high value of IRR (Investment Return Rate), over 40%;

2) Controllable and Consistent Straightening Effect: Customer can get promised uniform straightening effect from running of Wuxi JACK L Angle Steel Straightening Machine:

3) Wuxi JACK ASM100 model machine works at Russian customer facility: (Fig.5)

![Fig5 L Angle Steel Profile Straightening Machine 8 GEDC0485 Fig5 L Angle Steel Profile Straightening Machine 8 GEDC0485]()

4. Market Boom on the Machine: In a word, ever since Wuxi JACK ASM series Angle Steel Profile Straightening Machine being brought to market, this valuable machine tool gained high recognition and warm welcome, from customers not only in Chinese mainland, but also overseas abroad market;

5. Extensive Use of Wuxi JACK Machine: Up to now, Wuxi JACK ASM series machine have been exported to many countries, including Russia, East European countries, Central Asia, etc. And have acquired high approval from customers. It is now one of the featured products of Wuxi JACK;

6. Advantages of ASM Series Angle Iron Steel Straightening Machine in Summary:

The machine features in:

1) Safe, user friendly and simple operation;

2) High straightening speed;

3) Controllable, good and uniform straightening quality;

4) Easy and convenient installation, handling, relocation;

5) Low running and service cost;

In all, this machine can be widely used in many industries, such as Steel Structure, Iron Tower, Road and Bridge, etc.

C. Technical View on Wuxi JACK L Angle Steel Straightener Machine:

1. The Topics in Product Family of L Angle Steel Straightener Machine:

This product group of Wuxi JACK ASM series general purpose Angle Steel Profile Straightening Machine will give introduction in detail, being spread in each of the machine model product, covering the topics of:

1) Angle Steel straightening principle of the machine;

2) Angle Steel Straightening manipulation in the machine;

3) Operation process of the machine;

4) Main structure of the machine;

5) Safety operation on Angle Steel straightening job;

6) Service and maintenance on the machine;

2. Major Technical Characteristics of Wuxi JACK L Angle Steel Straightening Machine:

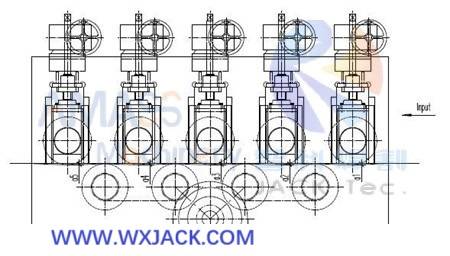

1) Straightening Principle on Angle Steel straightening is illustrated in below design sketch: (Fig.6)

![Fig6 Rolled Angle Steel Straightening Machine 28 Fig6 Rolled Angle Steel Straightening Machine 28]()

Shown in the above sketch, there are 5 pieces of straightening rollers being installed in higher level position, which move downward, exerting heavy straightening force on Angle steel. The 4 pieces of straightening rollers are installed at lower level position, just revolve without moving up and down;

2) Straightening cavity and its straightened Angle Steel being sent out of Wuxi JACK ASM models machine: (Fig.7)

![Fig7 L Angle Steel Straightener Machine 17 Fig7 L Angle Steel Straightener Machine 17]()

Shown in the above photo, the straightening rollers and its driving and transmission mechanisms are installed inside this operating cavity;

3) Up and lower assembled straightening rollers in Wuxi JACK ASM models machine: (Fig.8)

![Fig8 L Angle Steel Straightening Machine 13 Fig8 L Angle Steel Straightening Machine 13]()

Material and Process Technology: Shown in the above photo, the up position and lower position straightening rollers of our L Angle Steel Straightening Machine have different surfaces of concave versus concave. It is durable with top grade mechanical property, made of 35 chromium molybdenum, precisely machined and strictly heat treated;

4) Input and output roller tables of the machine: (Fig.9)

![Fig9 Angle Iron Steel Straightening Machine 3_20210619182345 Fig9 Angle Iron Steel Straightening Machine 3_20210619182345]()

Shown in the above photo, input and output roller tables of the machine have same design and structure, which can be exchanged based on on site condition at customer workshop.

D. Workpiece Size Range Applicable for Wuxi JACK Angle Iron Steel Straightening Machine:

Below are suitable Angle steels size range, for each of the standard model of Wuxi JACK ASM series Rolled Angle Steel Straightening Machine:

Specification of Angle Steel | Models of L Angle Steel Profile Straightening Machine |

ASM63 | ASM100 | ASM130 | ASM160 | ASM200 |

Min. Cross Section size (mm) | 20 ×20×3 | 30 ×30×3 | 40 ×40×4 | 50 ×50×5 | 60 ×60×5 |

Max. Cross Section size (mm) | 63 ×63×8 | 100 ×100×10 | 130× 130×10 | 160 ×160×12 | 200 ×200×16 |