A. Specialty, Working Principle and Application of Wuxi JACK XBJ Series Universal Plate Edge Milling Machine:

1. Our Strength: This machine is one of the knockout and advantageous products of Wuxi JACK company. This product family delivered from Wuxi JACK is in leading position in the industry and market for many years, involving design, production and delivery;

2. Working Principle of XBJ Universal Plate Edge Milling Equipment:

1) Plate Beveling Machine utilizes theory of high speed milling delivered with facer blade, producing various type of welding groove in high precision, on edges of workpiece metal plate;

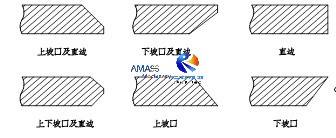

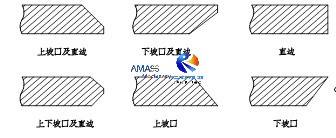

2) The bevels milled out Machine include Straight edge/ Slant edge/ U shape, etc., as shown in below sketch: (Fig.1)

3) The materials of metal plate that can be edge beveled in this machine include medium and low carbon steel, stainless steel, Al. etc.;

4) Samples of edge milled carbon steel plate from Wuxi JACK Edge Chamfering Machine: (Fig.2)

3. Application of XBJ Series Universal Plate Edge Beveling Machine:

1) Edge Milling Machine belongs to general purpose equipment. Across manufacturing industries, where there exists consumption of metal plate, especially steel plate to be used for producing final product, for which welding is a requisite process step, there exist demand on this general purpose machine for edge milling;

2) For example, facilities of Boiler, Pressure Vessel, Petroleum, Electric Power, etc. Depending on size of workpiece, each model of the equipment has its niche market.

B. Classification on XBJ Series Universal Plate Beveling Machine:

Depending on characteristics of steel plate and application scenario, there are several types of machine of different structure for customers selection:

1. Gantry Beam Structure Edge Milling Machine:

1) This group of Edge Milling Equipment is for cutting out welding grooves on medium size steel plates in medium speed;

2) The scopes of the steel plates sizes are: Thickness from 6mm ~ 60mm, length from 3,000mm to 18,000mm in general;

3) The edge milling working speed is adjusted with A.C. inverter and displayed instantaneously;

4) The XBJ-9 model single head configuration machine belongs to this category. It is a medium sized machine for sheet metal edge milling, with 9,000mm effective working stroke. In other words, available for machining on steel plates with Max. 9,000mm length;

5) This structure of Plate Beveling Machine, due to its widest application applicable for variety of applications, is named as “Universal machine for plate edge milling ”;

1) Equipped with super power 55kW milling head, this structure of plate moving type machine for edge milling has very high edge milling speed: Around 3~4 times that of the first type conventional Edge Milling Machine;

2) Such large scale machine for edge beveling is used for Oil and Pipeline Production site;

3. Trolley type Plate Edge Chamfering Machine, with Portable Structure:

This kind of compact Edge Milling Equipment aims at steel plates with small size and small thickness, for making chamfering in medium speed;

Utilizing roller shear, such Hobbing Cutter can make grooves on narrow plate with high efficiency.

C. Capability of XBJ-9 Universal Plate Edge Milling Machine:

1) This model of Edge Milling Equipment has one set of 7.5kW milling head and its moving carriage, performing plate edge milling task along the longest valid stroke of 9,000mm on metal plates;

2) Edge milling carriage which moves along the machine bed, or edge of steel plate, for carrying out edge milling welding groove, is driven with VFD (Variable frequency drive) motor;

3) The workpiece is pressed tightly during machine running, by means of a group of hydraulic jacks;

4) Adjustment of milling cutter for precise management is by hand, or with motor based on customer designation --- Spindle feeding position and cutter angle.

D. Technical Parameters of XBJ-9 Universal Plate Edge Milling Machine:

Model Technical Parameter | XBJ-9 Single Head Plate Edge Milling Machine |

Max. Plate Edge Milling Length | 9,000 mm |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Unit Feeding Motor | 2.2 kW |

Milling Head Quantity | 1 set |

Plate thickness for Sheet Metal chamfering | 6 ∼ 60 mm (Based on customer demand) |

Milling Angle of Top Milling unit | -25° to +45° |

Edge Milling Speed | 130 ∼ 1000 mm/min. VFD, Inverter Control) |

High Speed of Idle | 4000 mm/min. |

Applicable Diameter of Facer Plate | D= Ø125 ~ Ø320mm (Ø200mm For delivery) |

Quantity of Hydraulic Jacks | 12 pieces |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 500 mm |

Worktable Height | 1050 mm |