A. The Novelty Design of the SXBJ-12 Large Size Sheet Metal Plate Edge Milling Machine:

1. Is this a Single Head or Double Heads Plate Beveling Machine?

1) Viewing from either side of this special Edge Milling Equipment work table, you may think it is a set of single head machine for plate edge beveling, because there is only one set of milling head moving carriage installed on the work table of this large size machine;

2) However, if you go to the opposing side of machine work table, you will find there is also another group of milling unit carriage installed on the other side of the working table;

3) Which means, there are 2 sets of milling heads totally equipped with this large machine;

4) In this respect, on the aspect of milling head quantity, it is for sure a set of double heads Edge Milling Machine;

5) On the other hand, considering function of milling on welding groove on edges of steel plate, it is undoubtedly a set of single head machine for edge milling. Because with one set of milling head installed on either side of the machine work table, the Edge Beveling Machine can only cut out straight and top edge grooving on sheet metal, instead of bottom edge grooving;

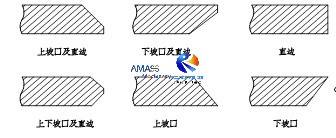

The welding grooves that can be cut from typical Edge Milling Machine: (Fig.1)

6) In this respect, this SXBJ-12 large size Edge Beveling Machine can be viewed as 2 sets of single head model machines, which are face to face integrated together into single set of integral Edge Milling Equipment;

2. The Reason on Special Design on SXBJ-12 Large Size Sheet Metal Plate Edge Milling Equipment:

There are two reasons on developing such novelty design machine:

1) The Special Steel Plates to be Beveled in this Edge Beveling Machine :

a) It is narrow width long length steel plate, which are cut from Strip Plate Flame Cutting Machine. Width of the steel plate is in the range of 100mm to 1000mm;

b) Both sides of these strip plates should be edge milled for milling on welding groove. So, it had better to be beveled on both sides at the same time, so as to getting high machining efficiency;

c) The strip plates applicable for SXBJ-12 special design Edge Milling Machine: (Fig.2)

d) Under such conditions, the SXBJ-12 Edge Beveling Machine works under the style of milling heads working at both sides of machine work table simultaneously: (Fig.3)

e) Working Video: Please check the attached video of this product section. It reflects on working condition and typical workpieces fitting for this special design End Grooving Machine;

2) Way of Steel Plate Loading and Unloading into Special Design Edge Milling Machine:

Workpieces can be loaded into the machine from both sides of its work table, to be flexible for adjusting on site material arrangement and disposal:

a) As can be observed from the attached first photo and below, this is a set of outdoors installed large size machine, which, different from indoors workshop, the process and material may change and be adjusted more frequently than usual;

b) With milling heads installed at both sides of work table, the End Grooving Machine can be swapped on its material loading and edge milling operation easily when necessary;

c) The outdoors installed SXBJ-12 Large Size Sheet Metal Plate Edge Milling Machine: (Fig.4)

From the above photo, you can view more clearly the double sides symmetrically installed milling heads carriages, onto this special design Edge Beveling Machine;

3) Here we stress that, in XBJ and SXBJ series Edge Milling Machine, this SXBJ-12 belongs to special design model, which account for around 5~ 10% of actual application in the machine product family, and should be denoted by customer specifically;

4) In the product group of such special design, there are some bigger sizes with more quantities of milling heads equipped, such as FXBJ-18 large size model machine, which has totally 4 pieces of milling heads in one set of the machine.

B. Electric Control Systems of SXBJ-12 Double Sides Operating Large Size Sheet Metal Plate Edge Milling Machine:

1. Cable Routing in the Plate Edge Beveling Machine:

1) Considering the working features of Plate Beveling Machine, the requirement on reliability of cable routing through the entire machine working zone is of vital importance, which should not got entangled during running of the milling head carriage along the machine working stroke;

2) Cable routing is by way of cable slides, assembled onto mechanical base bed of the Edge Milling Machine, the green color components: (Fig.5)

2. Electric Control Board of the Plate End Grooving Machine:

1) On each set of the XBJ and SXBJ series Edge Milling Machine milling head carriage, there is a piece of individual control board, together with its dedicated operating pendant:

2) The electric control board on milling head carriage: (Fig.6)

C. Technical Parameters of Novelty Design SXBJ-12 Large Size Sheet Metal Plate Edge Milling Machine:

Model Technical Parameter | Special Design Both Sides Operating SXBJ-12 Large Size Sheet Metal Plate Edge Beveling Machine |

Max. Plate Edge Milling Stroke | 12,000 mm |

Width of Workpiece Steel Plate | For both sides simultaneously beveling: 100mm ~ 1000 mm For single side beveling: Max. 3000 mm |

Milling Head Quantity and Installation Way | 2 sets, installed at both sides of working table |

Milling Angle Scope | 0° ~ 45° both sides |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Quantity of Work Table Hydraulic Jacks | 20 pieces |

Hydraulic Power Motor | 5.5 kW |

Plate Thickness for Sheet Metal Chamfering | 6 ∼ 50 mm |

Edge Milling Speed | 130 ∼ 1000 mm/min. (VFD, A.C. Inverter Control) |

High Speed of Idle Running | 4000 mm/min. |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 550 mm |

Worktable Height | 1050 mm |