1. The Large Model RH Series Versatile Edge Rounding and Trimming Machine:

In this product section of RH3000 we summarize on large models of RH series Edge Rounding Machine. We took the attached first picture on RH3000 at a Chinese customer of Shipbuilding facility.

2. Summary on RH3000 Versatile Edge Deburring and Rounding Machine:

General constructure of RH3000 model machine:

1) As can be seen from picture and below photo, RH3000 (And RH2000, RH1500) has mechanical main body of box gantry frame. It is fabricated and assembled into shape from welding structure members, section steels and steel plates:

Front view on Wuxi JACK RH3000 model machine: (Fig.1)

2) Advantage: Such kind of structure gives this automatic machine:

a) Sufficient firmness and strength for performing on edge rounding operation;

b) Besides, relative enclosed and relative opened operating area guarantees personnel safety and easy access;

3) In the entire set of large models gantry structure Edge Rounding Machine, routings of cable, compressed air pipelines, oil tubes can be arranged utilizing its cross beams and vertical columns, giving the machine a tidy, plain, compact and clear appearance.

3. Application of RH3000 Versatile Edge Rounding Trimming Machine:

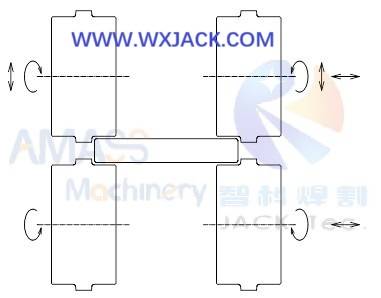

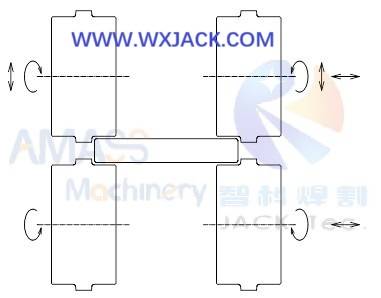

1) Edge Rounding Theory: The larger models of machine share the same edge trimming and rounding principle with smaller models. The illustration is shown below. For detail, please check product section of RH2000 model:

Way of plate edge trimming and rounding in Wuxi JACK Edge Rounding Machine: (Fig.2)

2) Different Application Field: Generally speaking,

a) The smaller model of RH800/ RH1000 models is more often used in T Beam Production Line and or H Beam Production Line;

b) While the larger models (RH1500, RH2000 and RH3000) are majorly used in manufacture of Shipbuilding, Port Machinery, Bridge Constructure, etc.

4. Operation and Maintenance of RH Series End Plate Trimming Machine:

1) The oil cylinders of machine help positioning and securing workpiece plate into its proper and accurate position for edge rounding:

Heavy force oil cylinders in Wuxi JACK RH models machine: (Fig.3)

2) The electric motor reducers of machine help carrying out edge rounding operation, in the way of sending plate moving forward, during edge trimming and rounding operation:

Motor reducers of workpiece conveying, in Wuxi JACK RH model machine: (Fig.4)

3) The air cylinder and its compressor help making clean working site of the Edge Rounding Machine;

4) The Emergency pushbuttons help guaranteeing on safety of operators as the last line of defense;

5) Adjustment in Edge Deburring and Rounding Machine:

Ahead of deburring and rounding, below adjustments are of vital importance on getting high quality delivery from this high precision machine:

Wide plate and its positioning into Wuxi JACK RH3000 model machine: (Fig.5)

The adjustment work mainly involves:

a) Modulate on workpiece plate into correct position by means of oil cylinders drive;

b) Coplanarity of edge rounding rollers with rollers along the input and output conveyors roller tables;

c) Collinearity of edge rounding rollers with side fend rollers;

6) Service and Maintenance of the Versatile Edge Rounding Machine:

a) We give detailed introduction in operating manual of the machine;

b) We give training on operating staff in the period of installation and commissioning at customer site;

c) We promise service terms for this RH series machine:

- Feedback within 24 hours;

- Propose ICA (Interim correct action) solutions within 24 hours;

- Propose root cause analysis and solution within 5 working days;

7) Summary on RH Series Versatile Edge Rounding Machine:

a) With this we wrap introduction on RH series machine, covering topics of usage, application, strong point, structure, main components, material and machining, operation and maintenance, etc.;

b) Hope these introductions can bring valuable information to customers around the globe having interest on this niche product machine.

5. Technical Parameters of RH3000 Versatile Edge Rounding Machine:

RH3000 Edge Deburring and Rounding Machine |

No. | Item | Parameter |

1 | Applicable Workpiece Width Scope | 150 ~ 3000 mm |

2 | Applicable Workpiece thickness | 10 ~ 40 mm |

3 | Applicable Workpiece length | 1000 ~ 12000 mm |

4 | Applicable H Beam Min. Web Height | 320 mm |

5 | Applicable Rounding Speed | 7200 mm/min |

6 | Rounding radius | R2.5 mm |

7 | Main rollers diameter | φ300 mm |

8 | Main rollers working life | 50,000m (On specific material) |

9 | Power of Hydraulic Pump Station | 4 kW |

10 | Max. Pressure in Hydraulic System | 12 MPa |

11 | Gas Pressure | 0.4 ~ 0.6 MPa |

12 | Input and Output Conveyor Length | 10m each |

13 | Machine Total Power | 10.6 kW |

14 | Electricity Specification | 380V, 50Hz, 3 Phase |