1. The Application of RH2000 Plate Edge Deburring and Rounding Machine:

1) The RH2000 Plate Edge Rounding machine for Port Machinery is the medium sized model of its product family, which is used for end trimming on various sizes of metal plates before fabrication and or painting;

2) Working moment of this RH2000 Plate Edge Deburring Rounding machine please see attached photo and below: (Fig.1)

2. Rounding Principle of RH Series Automatic Plate Edge Rounding Machine:

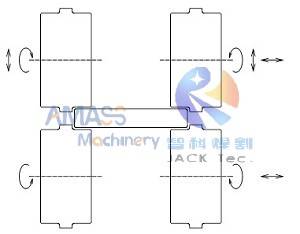

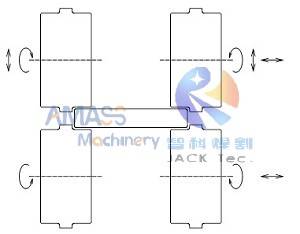

Please check below sketch of illustration on rounding principle in RH series End Plate Trimming machine: (Fig.2)

1) As you can check from above, there are two pairs of rounding rollers installed at left and right sides, inside the mechanical frame of the Plate Edge Deburring machine;

2) Each pair of the rounding rollers has top and bottom one piece of rounding roller each;

3) The bottom rounding rollers are driven with cycloidal gear motor alongside it. Or, in other words, in one set of the RH series Strip Edge Rounding machine, there are 2 sets of cycloidal gear motors, installed at left and right side of the machine frame respectively, for driving both sides of the bottom rounding rollers along transverse direction. Please check attached and below picture: (Fig.3)

4) During work of the Edge Rounding machine, the two pieces of bottom rounding rollers revolve, driven with the cycloidal gear motors, and thus in turn drive its top rounding rollers into revolve;

5) The four pieces of rounding rollers form up a cavity inside the RH Strip Edge Deburring and Rounding machine, for the purpose of edge rounding on working parts;

6) During work, workpiece travels forward going thru this rounding cavity, trimmed and rounded at the same time, fulfilling the task of deburring and rounding process, in this set of RH series Plate Edge Rounding machine;

7) This may reminds you the straightening principle at H Beam Straightening Machine. Definitely, there is something similar between the two equipment. All the standard models of RH series Edge Rounding machine, not only RH2000 of this product section, but also RH1000, RH1500, and RH3000, all share the same rounding process as introduced here.

3. Adjustment of Rounding Rollers in RH2000 Automated Plate Edge Rounding Machine:

1) From the above mentioned rounding principle inside this End Plate Trimming machine, we can see that the prerequisite for its proper operation is to have proper adjustment on the four pieces of rounding rollers, making it leaning against the top, bottom, and lateral surfaces of working parts firmly;

2) For this purpose, before rounding operation in this Edge Deburring Rounding machine, be sure to manage position of the four pieces of rounding rollers correctly, by means of the corresponding buttons on operating pendant. Please check the attached and below photo: (Fig.4)

3) During work of this End Plate Trimming machine, movement action of the four pieces of rounding rollers is driven with hydraulic oil cylinder. Please check attached and below picture: (Fig.5)

4) There are two sets of vertical acting oil cylinder respectively at each side of the rounding rollers, driving the top rounding rollers up and down, catering for various thickness of workpieces in the Edge Rounding machine;

5) Horizontal movement of the rounding rollers is driven with oil cylinder also. As introduced in previous sections of RH1500 Plate Edge Rounding machine, there are left and right, front and rear, totally four sets of oil cylinders for driving the rounding rollers moving toward or away from the workpieces, for adjusting its span based on width of the workpiece.

4. Technical Parameters of RH2000 Plate Edge Deburring and Rounding Machine:

Below are parameters of this RH2000 Edge Rounding Machine for dockyard:

| RH2000 Plate Edge Deburring Rounding Machine |

No. | Item | Parameter |

1 | Applicable Workpiece Width Range | 150 ~ 2000 mm |

2 | Applicable Workpiece Thickness | 10 ~ 40 mm |

3 | Applicable Workpiece Length Range | 1000 ~ 12000 mm |

4 | Suitable H Beam Min Web Beam Height | 320 mm |

5 | Edge Rounding Speed | 7200 mm/min |

6 | Finished Edge Rounding Radius | R2.5 mm |

7 | Main Rounding Rollers Diameter | φ300 mm |

8 | Hydraulic Station Power | 4 kW |

9 | Max. Pressure in Hydraulic System | 12 MPa |

10 | Input and Output Conveyor Length | 10m each |

11 | Edge Rounding Machine Total Power | 10.6 kW |

12 | Edge Rounding Machine Total Power | 380V, 50Hz, 3P |