The attached first and second photos were taken on the installation and commissioning of LHC model Column type I Beam Welding Machine (I Beam is the synonym of H Beam) at Wuxi JACK workshop.

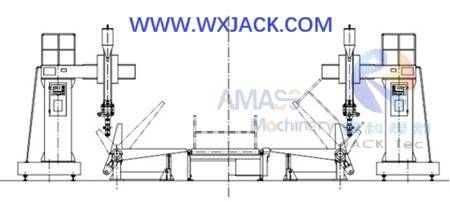

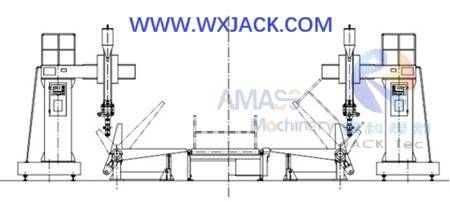

Design sketch on 2 sets of LHC model face to face: (Fig.1)

1. Working Process of LHC model Column type I Beam Welding Machine:

The below photo indicates on the on site layout of Wuxi JACK LHC column structure machine, running in SAW welding zone of automatic H Beam line, in a steel structure facility: (Fig.2)

1) By means of travel cart, the assembled and tack welded H beams from the previous station of H Beam Assembly Machine are put on the 60° Hydraulic Overturning Rack;

2) By means of the 60° hydraulic overturning rack, the H Beam is turned to 45° fillet welding position, for demanded orientation in the LHC Column type H I Beam SAW Machine;

3) During SAW welding stage in the LHC model machine, and controlled with automatic welding arc seam tracker unit, the welding torch moves in the three axes of X/ Y/ Z axis, making precise alignment on welding seam all the time:

Glimpse on working moment of Wuxi JACK LHC model machine, for H Beam SAW welding: (Fig.3)

4) Implication on X/ Y/ Z Axis in LHC Column type H Beam Welding Machine:

a) X Axis in LHC Model Machine:

i. This is for modulating on welding torch transverse movement along the long beam of the machine body;

ii. This movement can be controlled with handwheel (It is true with LHT T frame H Beam Gantry Welding Machine and LHAZ& LHAC gantry frame I Beam Submerged Arc Welding Machine also). Please check below picture marked in red color round:

Handwheel for adjusting on position of welding torch along horizontal: (Fig.4)

iii. Note: Some customer request motor control this direction movement. Under such condition, we install a motor on the transverse beam, and have toggle switch on the operating pendant to manipulate it;

b) Y Axis in LHC Model Machine:

This is for controlling the welding torch vertical movement along welding arm, motor drive. In other words, this movement adjusts on close to or away from welding seam of welding torch. It is accomplished with toggle switch on operating panel of the LHC machine;

c) Z Axis in LHC Model Machine:

This is for managing on the column trolley moving forward and backward along the rail during working process (Including both SAW and idle running): This movement is realized with trolley movement along rail, in other words, along H Beam. It is also for implementing on SAW welding operation on workpiece H Beam.

2. Stability of Column structure of LHC H Beam Welding Machine Running:

1) Potential Risk with Running of LHC Column type H I Beam SAW Machine:

As can be checked from its structure, for this LHC model, the machine body of trolley / upright column/ Overhead horizontal Beam has two apparent “issues”:

Mechanical frames of LHC model at Wuxi JACK workshop: (Fig.5)

a) The moving trolley structure is not as stable running, as the gantry frame structure in LHA series machine, or the T frame in LHT model machine. At least looks like this;

b) The moving trolley structure has smaller area for putting function components compared with LHA gantry and LHT T frame machines;

2) Consequently, to make sure stable running in both SAW welding period and idle moving stage in the LHC Column type H Beam Welding Machine, and do not have a cramped deployment,

Meaures Taken on LHC Column type I Beam SAW Machine by Wuxi JACK:

Wuxi JACK takes below actions in designing and manufacture of :

a) The moving trolley is double drive with double shaft in VFD (variable frequency drive) manner;

b) Welding speed is adjusted with turning knob within 10 folds range, and displayed in digital on operating pendant of the LHC model machine;

c) Instead of put on the trolley or on the beam, control board of the LHC Column type H Beam Welding Machine is integrated inside column, with operating pendant fit on the door.

Check below picture marked in red color square frame of Wuxi JACK LHC model: (Fig.6)

d) Trolley base has 30cm height, with transmission units of motor reducer fit inside. This also increases stability of the moving trolley in the process of LHC column structure Machine operation;

e) The transverse overhang beam is kept as short as possible: extension 1500mm.

3. Technical Parameters of LHC model Column type I Beam SAW Machine:

LHC Column type I Beam Submerged Arc Welding Machine |

Parameter | Specification | Note |

Operator Working Position | Stand on moving trolley of column body |

Applicable H Beam Flange Width (mm) | 200 ~ 800 |

|

Applicable H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

Applicable H Beam Web Height (mm) | 200 ~ 2000 |

|

Applicable H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

Applicable H Beam Length (mm) | 4000 ~ 12000 | Can be special made |

Gantry Travel Rail Length (mm) | 15000 | Can be special made |

Trolley Bed thickness (mm) | 300 |

|

Trolley Beam Extension (mm) | 1500 |

|