Background of This Blog on 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

1. Significance: In Steel Structure Industry, H Beam, or called I Beam, is the foremost raw materials in constructing any of the project, and hence the importance of various machine for H Beam production;

2. Business Acumen: Despite strong competitors on the market, as even more manufacturing and processing ventures, in order to be able to make their very own products getting the favor of clients;

3. Primary Benefits: In customer workshop, the introduction of exceptional H Beam Fabrication Machine to assist can not only improve the grade and degree of the business's operation, yet also lower the stress in terms of saving labor expenses, so the H Beam Production Line devices, especially this 3 in 1 H Beam machine, have become a top notch item that has been well obtained by the market product;

4. Core Topics: Let us have a concise exploration in this short blog, focusing on below 5 topics:

Strong Production Capacity of the machine;

Saving Cost Benefitting from the machine;

Strong Capability of the machine;

Working Style and Operation on the machine;

Summary and Wuxi JACK Leading Edges on the machine

A. Strong Production Capacity of 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

1. SAW Welding Role in 3 in 1 H Beam Fabrication Machine:

1) The SAW Integral Function 3 in 1 H Beam Welding Machine is widely made use for fabricating on H shaped steel beam in light/ medium/ heavy duty steel structures;

2) The PHJ and ZHJ series 3 in 1 machine can continually finish the setting up, welding parameters modulation, adjustment, and also discharging processes of T shaped and H shaped steel beam in the production procedure;

3) The SAW welding for making T Beam/ H Beam in Wuxi JACK 3 in 1 Vertical H Beam Welding Machine: (Fig.1)

![Fig1 3 in 1 Integral Function H Beam Welding Machine 197 Fig1 3 in 1 Integral Function H Beam Welding Machine 197]()

2. The Revolutionary Change Brought along with 3 in 1 Vertical H Beam Welding Machine:

1) Aspect: The production procedure embraces program control, and the change of welding speed takes on regularity conversion modern technology;

2) 3 Functions Integration: The 3 in 1 I Beam Fabrication Machine has incomparable benefits such as traditional device of H Beam Assembly Machine/ H Beam Welding Machine/ H Beam Straightening Machine, which can significantly enhance production capability, boost manufacturing performance, as well as minimize numerous production costs;

3) User Friendly and Conveniently producing T Beam/ H Beam with Wuxi JACK ZHJ15 model 3 in 1 H Beam Assembly Weld Straighten Integral Machine: (Fig.2)

![Fig2 3 in 1 H Beam Assembly Weld Straighten Integral Machine 24 Fig2 3 in 1 H Beam Assembly Weld Straighten Integral Machine 24]()

3. Improvement Get from 3 in 1 H Beam Fabrication Machine:

The advantages of the 3 in 1 machine are numerous:

1) Small impact, less driving, saving labor expenses;

2) No demand to weld pilot arc plates;

3) No setting up on SAW/ spot welding;

4) Conserve hoisting and logistics among the machine;

5) As well as remove waiting time in between H Beam Assembly Machine, H Beam Welding Machine and also H Beam Straightening Machine procedures;

6) Enhance Raised efficiency and also effectiveness in the process of welding T Beam/ H Beam production;

4. The Wuxi JACK PHJ15 model 3 in 1 H Beam Fabrication Machine exported to Australia in Aug. 2022: (Fig.3)

![Fig3 3 in 1 H Beam Assembly Welding Straightening Integral Machine 87 Fig3 3 in 1 H Beam Assembly Welding Straightening Integral Machine 87]()

B. Saving Cost Benefitting from Integral Function 3 in 1 H Beam Welding Machine:

1. This 3 in 1 I Beam Fabrication Machine:

contains 3 primary procedures for H Beam manufacturing:

1) Setting up: With H Beam Assembly Machine;

2) Welding: With H Beam Welding Machine;

3) Correcting the alignment of flange: With H Beam Straightening Machine;

2. Cost Saving from 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

1) One maker of the 3 in 1 machine finishes the work of 3 devices;

2) At the same time, it conserves labor for operating 3 tools and lowers labor expenses;

3) In this 3 in 1 machine, assembly / welding / correction is developed at one time, without repeated lifting and also loading and unloading;

4) Correspondingly, 3 in 1 Vertical H Beam Welding Machine saves the number of cranes, and saves the moment for training and raises the result.

C. Strong Capability of 3 in 1 I Beam Fabrication Machine:

1. Workpieces Available for being delivered from 3 in 1 H Beam Fabrication Machine:

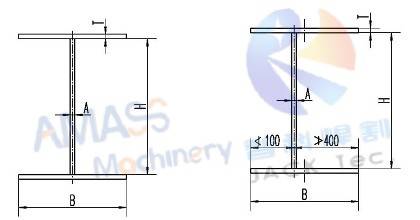

1) This machine can produce an H / I / T shaped beam of lights with balanced as well as asymmetrical cross sections. Shown in below sketch:

2) The 2 types of cross section H Beam to be produced from Wuxi JACK 3 in 1 H Beam Fabrication Machine: (Fig.4)

![Fig4- 3 in 1 I Beam Fabrication Machine Fig4- 3 in 1 I Beam Fabrication Machine]()

2. Fabricating Style in 3 in 1 Vertical H Beam Welding Machine:

1) This 3 in 1 machine can concurrently finish complying with procedures: Initial setting up as well as final assembly of the H / I / T Beam;

2) Carry out submerged arc welding on the beam in the vertical state;

3) Correction on the welding contortion of the H / I / T Beam;

4) Completing H Beam fabrication in vertical orientation from Wuxi JACK 3 in 1 Vertical H Beam Welding Machine: (Fig.5)

![Fig5 3 in 1 Vertical H Beam Welding Machine 6 Fig5 3 in 1 Vertical H Beam Welding Machine 6]()

D. Working Style and Operation on 3 in 1 Vertical H Beam Welding Machine:

1. Working Style in the 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

1) The PHJ and ZHJ model automated SAW 3 in 1 machine is outfitted with a welding process managing system to get the optimum performance;

2) The setting up and welding of the H Beam is an automated mode, in the 3 in 1 machine;

3) Throughout manufacturing, the program control monitoring can be made use of to readjust the working speed, for assembling/ welding/ flattening beam, to guarantee the top quality of the fabrication;

4) One set of 3 in 1 machine device can support 3 devices, which is more effective than 3 gadgets;

5) Process Parameter Control Panels in Wuxi JACK 3 in 1 machine: (Fig.6)

![Fig6 3 in 1 H Beam Fabrication Machine 26 Fig6 3 in 1 H Beam Fabrication Machine 26]()

2. Operation on the 3 in 1 I Beam Fabrication Machine:

1) Added Value: This integral function 3 in 1 machine saves electrical energy expenses, conserves flooring area, reducing number of employees from 6~ 7 to only 1, so as to conserves rental costs as well as labor costs;

2) Nature: All of these factors end up being pure profits for customers, and several advantages are revealed. Accordingly, the 3 in 1 H Beam Fabrication Machine is presently a collection of equipment, that is better for steel framework production lines;

3) Problem Solved: With the help of the SAW machine, the precision of placing can be said to be better enhanced; Inside, it is unpreventable that there will certainly be a specific escape. Such unprofessionalism is naturally a defect in the eyes of clients;

4) High Efficiency: Standard hand operated positioning, not just due to the restricted personnel, will certainly enhance the trouble of the alignment period of the 3 in 1 machine. Likewise, since it is a manual procedure, so in terms of accuracy, it is impossible to make certain that each batch of internet reaches the clinical and affordable range;

5) Managing on Wuxi JACK 3 in 1 H Beam Assembly Welding Straightening Machine: (Fig.7)

![Fig7 Integral Function 3 in 1 H Beam Welding Machine 5 Fig7 Integral Function 3 in 1 H Beam Welding Machine 5]()

E. Summary and Wuxi JACK Leading Edges on 3 in 1 H Beam Fabrication Machine:

1. Over the past two decades, Wuxi JACK maintains our solid leading position in the field of H Beam production machinery delivery, especially this machine.

2. Our Superiorities on 3 in 1 I Beam Fabrication Machine cover full range of:

1) Advanced and delicate design;

2) High quality and robust quality, hence long service life for customers;

3) Wide variety of models, structures, and configuration.