Machine Usage: The LHA model Gantry frame I Beam Submerged Arc Welding Machine produces welding H Beam (I Beam) with advanced SAW (Submerged arc welding) technology of Single Arc, Twin Arc, or Tandem Arc, depending on customer demand or practical condition.

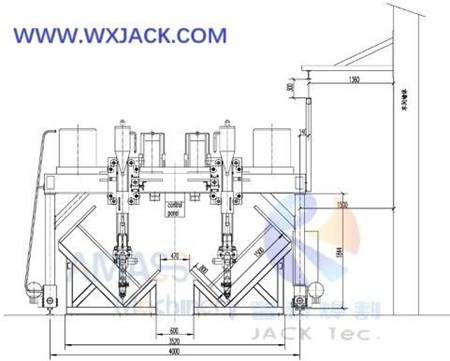

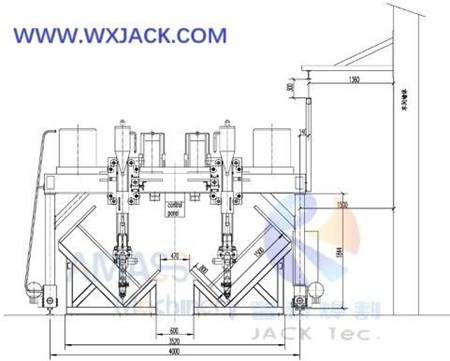

Design prints on Wuxi JACK LHAC (Side control) and LHAZ (Center control) machines: (Fig.1,2)

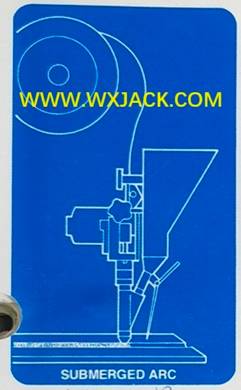

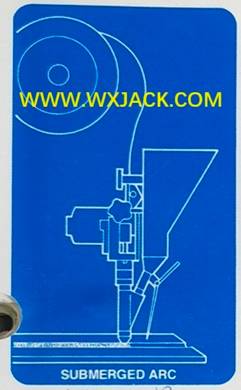

1. Single Arc of SAW Technology in LHA Gantry frame H Beam SAW Machine:

Denotation: This refers to “Single piece of welding wire generates single welding arc”: (Fig.3)

1) With this type of SAW technology, welding height of each pass of welding seam is around 10mm;

2) In such case, one set of welding power source (Welding machine) is used for welding one piece of workpiece;

3) So, for LHA model machine (T type LHT H Beam Welding Machine also), one set of the machine should be equipped with two sets of welding power source (Because two pieces of H Beam are welded at the same time in the machine):

2 pieces of H Beam can be SAW welded simultaneously in LHA series machine: (Fig.4)

4) As for the column frame LHC H Beam SAW Machine, one set of the machine should be equipped with one set of welding power source only (Because one piece of H Beam is welded at any working moment of this type of machine):

There is one piece of H Beam available for welding in LHC model, which is usually applied in automatic H Beam line: (Fig.5)

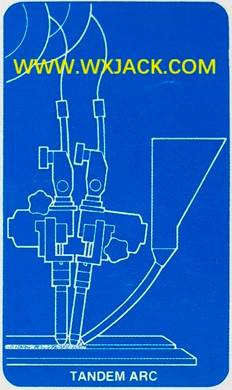

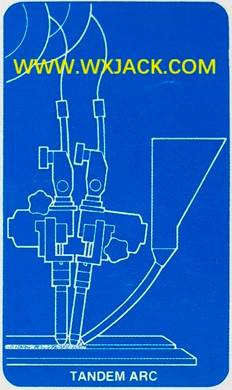

2. Tandem Arc of SAW Technology in LHA Gantry frame H Beam Welding Machine:

Denotation: This refers to “Two pieces of welding wire generate double welding arc”. With such type of SAW, welding height of each pass of welding seam can be up to 20mm: (Fig.6)

1) For this reason, for the H Beam with web thickness above 20mm (usually we call such H Beams as “thick ones”), customers have two options on the configuration of machine:

2) Either adopts with Single Arc discussed in the previous segment. The Gantry frame I Beam Welding Machine moves back and forth along the rail two times, and at the same time apply SAW on the H Beam two times;

3) Or, adopts with Tandem Arc of this segment. Under such condition, the LHA model gantry frame machine can finish SAW on the H Beam with one pass welding. So, it doubles productivity also;

4) With Tandem Arc introduction, two sets of welding power source should be used for one piece of H Beam welding. Or, in other words, four sets of power source should be equipped into one set of LHA model H Beam Welding Machine (This is true with LHT H Beam SAW Machine also; While for one set of LHC column type machine, it should be two sets of power source).

3. Twin Arc of SAW Technology in LHA Gantry frame H Beam Welding Machine:

This refers to “Two pieces of welding wire generate single welding arc”. It is usually applied in Flat Fillet welding position on H Beam: (Fig.7)

1) Flat Fillet welding means the workpiece is put flat at horizontal position, while welding torch is at 45°; The PHJ and ZHJ series H Beam Assembly Weld Straighten Integral machine developed by our company is adopted with Flat Fillet welding;

2) As comparison, the 45° Fillet welding used in LHT/ LHC/ LHA H Beam Welding Machine is, workpiece H Beam is put at 45° position, while welding torch is at straight vertical downward position;

3) Flat fillet welding is not as easy as 45° fillet welding in terms of producing welding seam of good appearance. However, with adoption of Twin Arc, this target can be met;

4) Also, Twin Arc can raise welding speed around 5%, making contribution to high efficiency of production in the machine;

5) To have an intuitive compare on Flat Fillet welding applied in PHJ&ZHJ H Beam Assembly Weld Straighten Integral machine, with the 45° Fillet welding (both types belong to submerged arc welding) applied in LHC column type& LHT T frame & LHA large I Beam gantry welding machine, please check below photo:

H Beam position in 3 in 1 Machine: (Fig.8)

4. Technical Parameters of LHA Gantry frame H Beam Welding Machine:

LHA Series Gantry frame I Beam Submerged Arc Welding Machine |

Parameter | Specification | Note |

H Beam Flange Width (mm) | 200 ~ 800 |

|

H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

H Beam Web Height (mm) | 200 ~ 1200/ 1500/ 1800/ 2000 | Varies on models |

H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

H Beam Length (mm) | 4000 ~ 15000 | Can be special made |

Submerged Arc Welding type | 45° fillet welding |

|

Submerged Arc Welding mode | Single Arc, Or Tandem Arc |

|

Welding Power Source quantity | 2 sets in the case of Single Arc, And 4 sets in the case of Tandem Arc | Machine quotation is different as in the case of Single Arc and Tandem Arc |