Background: The attached photos were taken on a set of Wuxi JACK LHA5C model side control H Beam Gantry Welding Machine, which was exported to Bangladesh in the year 2019.

1. The Applicable Workpiece for LHA5C Gantry type H Beam SAW Machine:

a) The Largest Model of its Type: LHA5C side control model machine produces H Beam with web height of up to 2,000mm, which is the largest model in LHAC series sub group, same as LHA55Z is the largest model in center control type LHAZ series sub group of H Beam Submerged Arc Welding Machine;

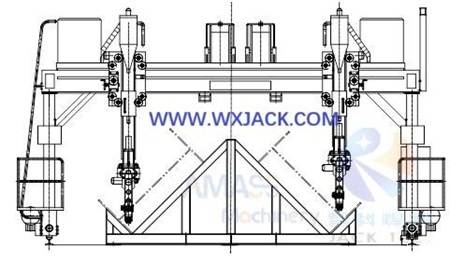

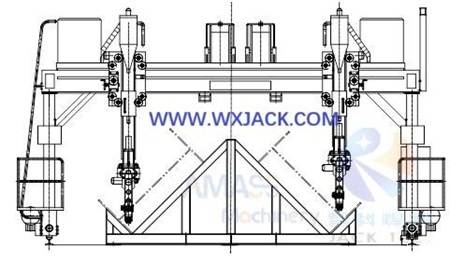

b) As review, for gantry sketch of side control machine, please check below illustration: (Fig.1)

2. Outline on Usage and Operation of LHA5C Gantry type I H Beam SAW Machine:

1) Task: This automated machine is for fulfilling on automatic SAW (Submerged arc welding) on H Beam;

2) Position in Process Technology: After being assembled and spot welded in Z15/ Z18/ Z20 H Beam Assembly and Tack Welding machine, the H Beam is put on the supporting racks of the LHA5C model machine, in the flat position of 45° fillet weld. (The supporting racks are put and fixed on the workshop floor beneath the gantry):

Finished SAW welded H Beam on support rack of Wuxi JACK LHA5C machine: (Fig.2)

3) Degree of Freedom: In the SAW process of LHA5C model machine, on its front face horizontal beam, the two pieces of motorized moving carriages which are fit with two sets of SAW welding torch, which can move leftward and rightward along transverse beam of the gantry, as well as moving up and down along the two pieces of vertical arms installed on the transverse beam of gantry;

4) In this way, during working of the LHA5C model Gantry type I H Beam SAW Machine, the two sets of welding torches can move along three axis of X/ Y/ Z, making sure its welding tip precisely aiming at welding seams all along (The forward and backward movement of welding torches in horizontal plane is realized with gantry travel along the rails):

The 2 sets of welding carriages and installed welding torches unit in Wuxi JACK LHA5C machine: (Fig.3)

5) Welding Support Function Cell: In one set of LHA5C model I H Beam Submerged Arc Welding Machine, there are two sets of automatic welding seam tracing unit, which are assembled at the front end of the abovementioned two pieces of carriages (one tracing unit in one carriage each):

Welding seam tracker: (Fig.4)

6) Welding Operation in Machine: For implementing on SAW on H Beam, gantry moves along rails of the H Beam SAW Machine, performing automatic SAW welding on the two pieces of H Beam:

Overall view on running of LHA5C machine for SAW welding on 2 pieces of H Beam simultaneously: (Fig.5)

7) SAW Welding Flux Hopper: The LHAC series machine is also equipped with automatic Flux Deposition and Recovery unit, 2 pieces in a set of machine: (Fig.6)

3. Major Components in LHA5C Gantry type H Beam Submerged Arc Welding Machine:

As introduced in product section of “LHA4C Side Control Gantry type Models”, the LHAC series machine is mainly composed of:

1) Motor drive moving gantry, moves along rails, skeleton of the machine;

2) Transverse motor drive moving carriages, 2 pieces, working base and core working units of the machine;

3) SAW welding torch mechanical tracker, 2 pieces, precondition on guanranteeing stable and superior welding quality;

4) SAW welding machine, 2 sets, or called welding power supply, major outsourced function units of H Beam Welding Machine;

5) SAW welding flux recovery and recycling unit, 2 sets, indispensable for SAW operation;

6) Gas system and electric control system.

4. Transmission of Welding units in LHAC Gantry type H Beam SAW Machine:

Proper transmission of working motions is critical in guaranteeing on high standard delivery of high quality H Beam from the LHAC series gantry type machine:

1) By means of two sets of adjustable eccentric roller and high precision V section rail, vertical and horizontal smooth movement of welding torches can be fully guaranteed: (Fig.7)

2) The horizontal movement of carriages along gantry is controlled with handle reducer and gear rack unit;

3) Vertical motion of welding torch along welding arm is fulfilled with motor reducer and gear rack.

5. SAW Process Controlled with Arc Tracing unit of LHAC Gantry type H Beam Welding Machine:

1) The two sets of arc tracing unit serve as feedback of welding process, sending signal to control system of the LHAC machine, and thus two sets of welding power supply accordingly. To be specific, it monitors on welding process of SAW, and sends back detecting signal to control center, forming a closed loop negative feedback control system of SAW process in the machine;

2) These two sets of welding arc tracing unit are designed and made by us (Wuxi JACK), and installed on the welding carriages on the transverse beam of the H Beam SAW Machine gantry.

6. Technical Parameters of LHA5C H Beam Gantry Welding Machine:

LHA5C Gantry type H Beam SAW Machine |

Parameter | Specification | Note |

Operator Working Position | Both sides of Gantry, external sides of supporting racks |

H Beam Flange Width (mm) | 200 ~ 800 |

|

H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

H Beam Web Height (mm) | 200 ~ 2,000 |

|

H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

H Beam Length (mm) | 4000 ~ 15,000 |

|

Gantry Span (mm) | 5,000 |

|

Gantry Travel Rail Length (mm) | 18,000 |

|