A. The Function of 5 Axis 2500/12 Large Size Flame CNC Pipe Intersection Cutting Machine:

1. The below photo was taken during commissioning of Wuxi JACK 5 Axis 2500/12 Flame CNC Pipe Cutting Machine: (Fig.1)

2. The Max. Workpiece that can be Cut in 5 Axis 2500/12 Large Size Flame CNC Pipe Cut Machine is cross section diameter Φ2500mm and 12m long:

A piece of large diameter cut and beveled from Wuxi JACK Flame CNC Pipe Intersection Cut Machine: (Fig.2)

3. Same as the previous model of 5 Axis 2500/9, here the product 5 Axis 2500/12 is the replenishment on early models of CP series Plasma Oxy-fuel CNC Pipe Intersection Cutting Machine, catering for the sub-division on more segmented workpiece size.

B. Detail Delicacy in Wuxi JACK Large Scale Flame CNC Pipe Cutting Machine:

1. With nearly 20 years of development, the CP series Automatic Plasma Oxy-fuel CNC Pipe Intersection Cutting Machine sees many improvements involving structure design, assembly and component, hardware and software of control system, etc.;

2. Compared with the machine at its inception stage, the Automatic Flame CNC Pipe Intersection Cutting Equipment of today becomes nearly new version of CNC Pipe Cutting Machine. It makes progress toward the target of best safety, better quality, more consistent performance, and easier operation, under the principle of Wuxi JACK “Continuous Improvement”;

3. Example on Cable and Oxy-fuel Tubes Arrangement in Wuxi JACK Flame CNC Pipe Cut Machine:

One of these improvements is the arrangement on oxy-fuel gas pipe and cable, throughout the whole traveling stroke of cutting torch in the CNC Pipe Intersection Cutting Machine:

1) At the early stage of CP series Automatic Plasma Oxy-fuel CNC Pipe Cutting Machine, the oxy-fuel gas pipes were hanged overhead alongside the equipment, especially in the small model of 3 Axis 600mm specification CNC Pipe Cut Machine;

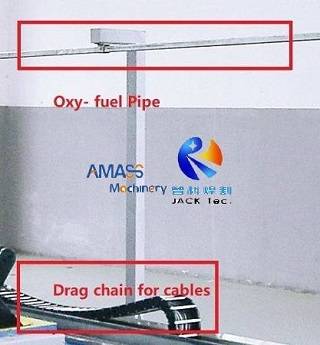

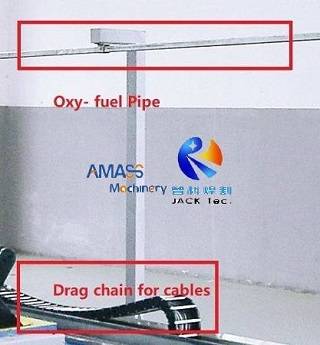

2) And cables were laid within drag chain. The drag chain was put onto floor closely with the mechanical frame of the CNC Pipe Intersection Cut Machine. Please check below picture:

Cable and gas tube routing in early small models of Wuxi JACK CNC Pipe Cutting Machine: (Fig.3)

3) Such way of arrangement in Flame CNC Pipe Cut Machine has 2 issues and problems of:

a) The CNC Pipe Cutting Machine itself does not have good appearance (Oxy-fuel pipe had better be placed invisible);

b) Due to the close distance between cutting torch and cable, there exist certain degree of safety potential risk to the CNC Pipe Cutting Machine, that sparks may be generated during cutting process, which in turn cause cable into burning;

4) Today, the placement of cables and oxy-fuel pipes inside CNC Pipe Intersection Cutting Equipment, especially large size heavy duty CNC Pipe Intersection Cutting Machine is improved in large extent:

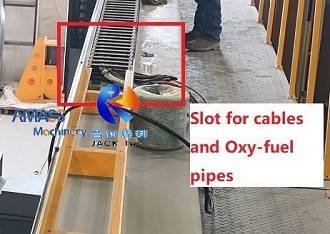

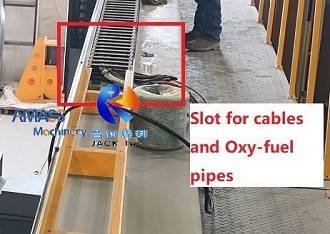

Please check below picture:

a) Cable and gas tubes routing in updated large CNC Pipe Intersection Cutting Machine: (Fig.4)

b) As shown in the above photo, the cables and oxy-fuel pipes are laid into the same slot with half meter interval, and in the height level right above the entire set of CNC Pipe Intersection Cutting Equipment, deployed on the operating platform;

c) In this way, the previously mentioned safety hidden risk can be eliminated reliably;

d) Besides, the whole set of large CNC Pipe Cutting Machine has more compact and concise appearance.

C. Technical Parameters of 5 Axis 2500/12 Large Scale Heavy duty CNC Pipe Intersection Cutting Machine:

Below is specification of 5 Axis 2500/12 Flame and Plasma Automatic CNC Pipe Intersection Cut Machine:

Model Technical Parameter | 5 Axis CNC-CP 2500/12 Large Scale Heavy duty Flame CNC Pipe Cutting Machine |

Fitting Diameter Range of Pipe | 500 ~ 2500 (mm) |

Fitting Max. Length of Pipe | 12000 (mm) |

Fitting Thickness of Pipe (mm) | 6~100 mm for flame cutting 3 ~ 25mm for plasma cutting |

Fitting Cutting Speed Of Flame and Plasma | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

CNC Control Axis | 5 Axis of X/Y/Z/A/B X Axis: For cutting torch positioning along pipe length; Y Axis: For pipe CW/CCW rotation; Z Axis: For Moving up and down cutting torch; A Axis: For tilting cutting torch along pipe radius; B Axis: For tilting cutting torch along pipe length |