A. Position of 3 Axis 600/12 Basic Configuration Chuck Claw Oxygen Fuel Plasma CNC Pipe Cutting Machine:

1. Every model in the product family of CNC-CP series CNC Pipe Cutting Machine has its personality and significance, which was developed echoing certain market demand, and this is no difference to the “Basic configuration” chuck claw configuration of this product section;

2. In fact, the model of 3 Axis 600/12 is the start point of the entire product family. As we know, each time the development of new product always starts with the simplest type with the most compact dimension, and this is true with this machine of task on CNC control pipe cutting;

3. This is the earliest model of machine developed in its early stage around 20 years ago, in the year around 2005. Later on, with the mature of both hardware and software technique, and growing of the pipe cutting market, both control axis of CNC and size of workpiece have gone thru increasement in the machine: From 3 Axis to 5 Axis/ 6 Axis/ 7 Axis, from Φ600mm to Φ1400mm/ Φ2000mm/ Φ3000mm CNC Pipe Intersection Cutting Machine.

B. Function of 3 Axis 600/12 Basic Configuration Chuck Claw Oxygen Fuel Plasma CNC Pipe Cutting Machine:

1. The 3 Axis 600/12 model machine is the “simplest” one in its product family. It has basic function of plasma and Oxygen fuel flame cutting on pipes, controlled with CNC in the machine;

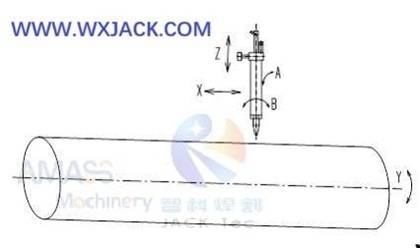

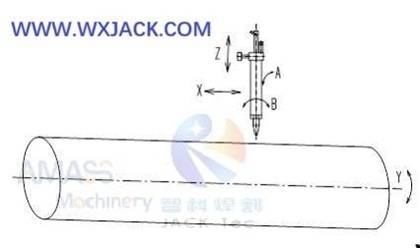

2. The 3 Axis in CNC System of CNC Pipe Cutting Machine are: (Fig.1)

1) X Axis: Cutting torch can be adjusted along length direction of workpiece;

2) Y Axis: Workpiece pipe rotates, so that cutting torch always directs at 12 o’clock position on the workpiece, during cutting operation in the machine;

3) Z Axis: Cutting torch can be moved up and down, so that be fitting for different diameters of workpiece;

3. Output: With the above 3 Axis control, this chuck claw CNC Pipe Intersection Cutting Machine can cut off the pipe into required length, and or cut holes of various diameters in the pipe, without slant angle beveling function. Following that, it can be welded with flange, in the Pipe Flange Circumferential Welding Machine;

4. The max. pipe diameter suitable for pipe cutting is 600mm, length 12m. No restriction on thickness of workpieces wall;

5. For the basic configuration of 3 Axis control machine, the specification of Φ600mm is the most fitting model. Because usually the smaller the diameter, the smaller thickness of pipe wall, which means less need on oblique beveling function in the CNC Pipe Cutting Machine.

C. Mechanical Features of 3 Axis 600/12 Chuck Claw CNC Pipe Intersection Cutting Machine:

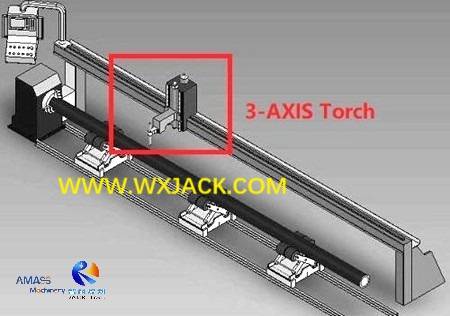

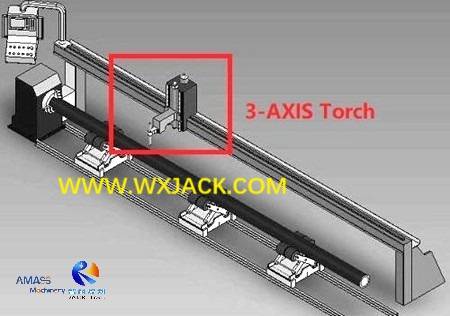

1. Chuck Claw Fixture for Workpiece Secure in the Oxygen fuel Plasma CNC Pipe Cut Machine: (Fig.2)

As we mentioned in the product section of “Complicated Control 6 Axis 600/12 model”, chuck claw has the implication of specifically for Φ600mm specification pipe secure. Larger than that, the pipes are not fitting for being clamped with chuck claw any more;

2. Cutting Torch Movement in the 3 Axis Basic Configuration CNC Pipe Cutting Machine: (Fig.3)

Illustrated in the above sketch, the cutting torch for 3 Axis machine has straight structure of vertical movement, without revolve and swing.

D. When to Choose Basic Configuration 3 Axis CNC Pipe Cutting Machine?

1. For customers do not need edge beveling on their mall diameter pipes, this model of 3 Axis 600/12 machine is proper choice: It has inexpensive price, easy operation, short time installation and commissioning, as well as convenient maintenance;

2. Besides, due to the modular design of CNC Pipe Cutting Machine structure, and easy expansion on interface of control system, including both hardware and software, this basic configuration 3 axis CNC machine is available for later on upgrade into 5 axis and or 7 axis control models when necessary.

E. Technical Parameters of 3 Axis Basic Configuration Chuck Claw Oxygen Fuel Plasma CNC Pipe Cutting Machine:

Model Technical Parameter | 3 Axis CNC-CP 600/12 CNC Pipe Intersection Cutting Machine |

Applicable Pipe Diameter Range for Cutting | 80 ~ 600 mm |

Max. Length of Pipe for Cutting | 12,000 mm |

Applicable Pipe Thickness Range for Cutting | 6~ 100 mm for flame cutting; 3 ~ 25mm for plasma cutting |

Applicable Oxy-fuel and Plasma Cutting Speed | 200∼ 800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

CNC Control Axis | 3 Axis of X/ Y/ Z: X: Pipe length direction; Y: Pipe Rotates; Z: Pipe elevation |