A. Application and Usage of CP6-1400/15 Flame and Plasma CNC Pipe Cutting Machine:

1. The 6 Axis Φ1400mm Series CNC Pipe Intersection Cutting Machine:

Is the sophisticated version for small to medium diameter range of pipe, and a special made model:

1) Generally speaking, the 5 Axis control models can meet on majority demand on pipe beveling and chamfering, for small to medium size pipe:

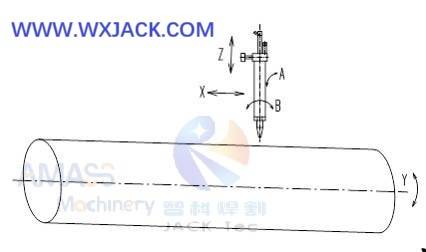

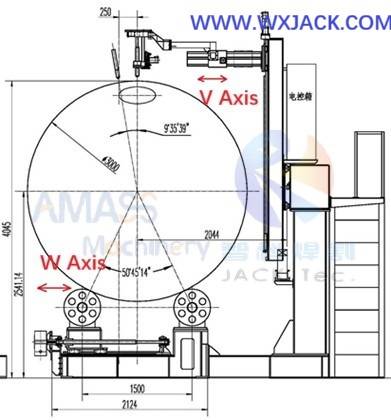

2) The 5 Axis Denotation in CNC control pipe cutting: (Fig.1)

2. On the other hand, there do exist certain conditions that calls for sophisticated cutting and beveling for medium diameter pipes, and hence comes 6 axis configuration:

Applicating Examples on Sophisticated 6 Axis CNC Pipe Cut Machine:

1) For machining on stainless steel materials/ Alloy steel of pipes;

2) Plasma cutting on pipes;

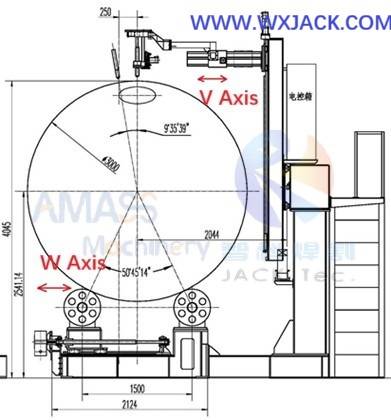

3. The 6th axis V axis in Plasma and Flame CNC Pipe Intersection Cutting Machine, for controlling cutting torch movement along pipe radius direction: (Fig.2)

1) This means the positioning of cutting torch along pipe radius way is controlled not only with pipe rotation Y axis, but also with V axis;

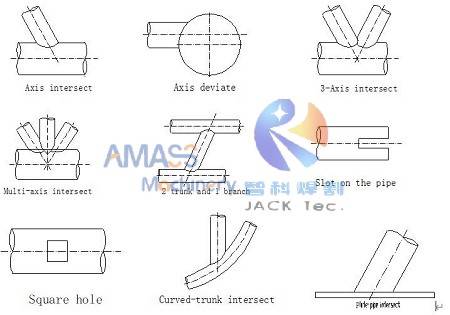

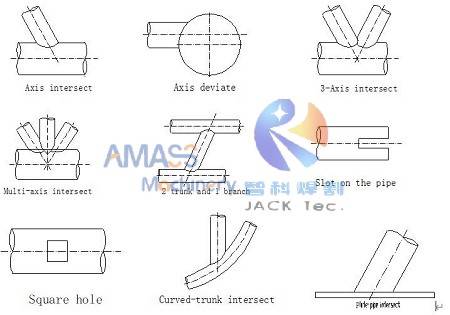

2) The 9 types of typical bevels on pipes, available for being cut from 6 axis CNC Pipe Cutting Machine: (Fig.3)

B. Major Units in CP6-1400/15 CNC Pipe Cutting Machine:

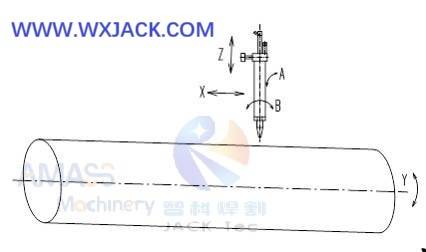

1. Cutting torch in 6 Axis models machine: (Fig.4)

Specialty of the Cutting Torch: As can be found from the above photo, the cutting torch equipped in 6 axis and 7 axis configuration machine has angular ruler for measuring on its tilting angle, as well as mechanism for 360° infinite swiveling unit;

2. Electric Control System of CP6-1400/15 CNC Pipe Intersection Cutting Machine:

1) Capability: Control system of the machine has all the control function and hardware configuration necessary for pipe intersection cutting operation, which conforms to Chinese national electric standard and IEEE, in terms of insulation/ Protection/ Cable arrangement;

2) Depends on practical condition at customer site, the control board of CP series machine can be either of worktable style, or in the way of overhanging pendant;

3) For this medium size Φ1400mm specification CNC Pipe Cut Machine, this is standing worktable type: (Fig.5)

4) Worktable in medium size sophisticated CP6-1400/6 model machine is easy in operation, conforming to strict standard on the aspect of design/ radiation/ insulation and cable arrangement, fully taking into account rigorous environment and shield interruption of flame cutting and plasma cutting, ensuring long term and normal working of the CNC Pipe Cutting Machine;

5) All the input and output control signal of the control board are isolated with I/ O board. The elements are reasonably arranged, and cables are tidily laid, along the whole length of machine working site.

C. Precondition on Workpieces in CP6-1400/15 CNC Pipe Intersection Cutting Machine:

1. Pipes of CNC Pipe Intersection Cutting Machine :

To fully guarantee high quality finished products, raw material should meet the precision demand of

1) Roundness of pipe: Ovality of the cross section of pipe should not exceed 0.5% that of the pipe diameter;

2) Welding reinforcement on longitudinal seam of pipe: If this welding reinforcement is protruding enough to affect smooth revolve of pipe during pipe cutting, it needs to be grounded off ahead of time;

2. In all, to have this sophisticated CP6-1400/15 CNC Pipe Cutting Equipment fully delivering satisfactory performance, every detail involved should be taken good care.

D. Technical Parameters of CP6-1400/15 CNC Pipe Cutting Machine:

Model Technical Parameter | 6 Axis CNC-CP 1400/15 Sophisticated CNC Pipe Intersection Cutting Machine |

Diameter Range of Pipe | 300 ~ 1400 (mm) |

Max. Length of Pipe (mm) | 15,000 |

Thickness of Pipe (mm) | 6~ 100 mm for flame cutting; 3 ~ 25mm for plasma cutting |

Cutting Speed | 200 ∼ 800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

CNC Control Axis | 6 Axis of X/ Y/ Z/ A/ B/ V X Axis: For cutting torch movement along workpiece length Y Axis: For pipe infinite rotation; Z Axis: For cutting torch up and down; A Axis: For tilting cutting torch along workpiece radius; B Axis: For tilting cutting torch along pipe length; V Axis: Cutting torch lateral movement |