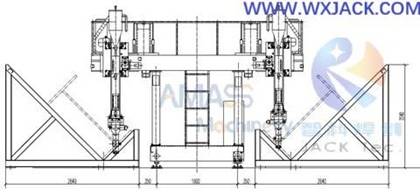

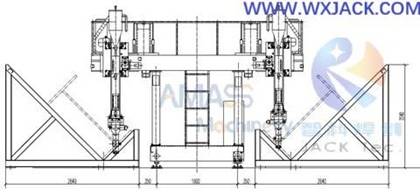

Appearance and on site working condition of Wuxi JACK LHT model H Beam Gantry Welding Equipment please see the attached photos. Its design sketch please see below: (Fig.1)

1. Function of LHT Model H Beam Gantry Welding Machine:

1) Function: The LHT is a kind of classical automatic machine. It is used for accomplishing submerged arc welding on H Beam in the form of Single Arc or Tandem Arc, following the step of assembling and tack welding in the process technology of welding H Beam production;

2) Using Site: Same as LHA series (LHAC side control and LHAZ center control) gantry frame moving machine, LHT model model machine is not used in fully automatic H Beam Production Line. Instead, this LHT model machine is worked as independent H Beam Welding Machine. One operator can manage its working process:

Installed Wuxi JACK LHT model machine at steel structure customer workshop: (Fig.2)

2. SAW Welding Flux Recovery Units in LHT Model Gantry type H Beam Welding Machine:

1) Importance of SAW Flux Recovery Unit in H Beam Welding Machine:

All the operation of SAW welding should be equipped with welding flux automatic recovery and recycling unit. It is requisite unit for getting stable/ controllable/ top level performance of SAW (Submerged arc welding) process. So, besides LHT model, the LHA gantry structure and LHC column structure machines are all equipped with this unit also;

2) Working Principle of SAW Flux Recovery unit in H Beam Welding Machine:

a) During the SAW welding operation, welding flux flows onto welding seam by way of flux hopper (the yellow one fit at front side of the machine gantry beam, see below picture marked with red color square frame) and manual valve, guaranteeing on normal welding procedure implemented in the machine:

Front view on Wuxi JACK H Beam SAW Welding Machine: (Fig.3)

b) Welding flux recovery tube recycles redundant flux following welding tip for next time use;

c) By screening of sieve, those fluxes that can be recycled will flow into flux hopper again by way of manual valve;

d) Dust is collected into flux recovery unit, and those flux in block remains inside flux hopper.

3. Pneumatic System in LHT Model H Beam Gantry Welding Machine:

1) Major Drive Mode on Operation: As explained in the product section of LHT, all the H Beam SAW Welding Machine do not have hydraulic system. Power momentum for machine operation is supplied with motor reducer and air cylinder;

2) The welding arc tracker systems in these machines utilizes on both mechanical style and pneumatic style, eliminating common problems with solitary mechanical unit, including huge impact, high failure rate, unreliable tracking, etc.:

Wuxi JACK exclusively owned welding arc tracing unit for SAW operation: (Fig.4)

3) By pre-setting on the air cylinder, welding torch is guided along the welding seam all the while during the whole SAW welding in the machine, with stable running and good welding quality.

4. T Frame Movement along Rail of LHT Model H Beam Gantry Welding Machine:

1) Same as column style LHC model and LHA model gantry frame machines, T frame movement of the LHT model machine can be shifted between high speed (Idle, 3,200mm/min.) and low speed (welding, 240 ~ 24,00mm/min.), during operation period, based on practical need:

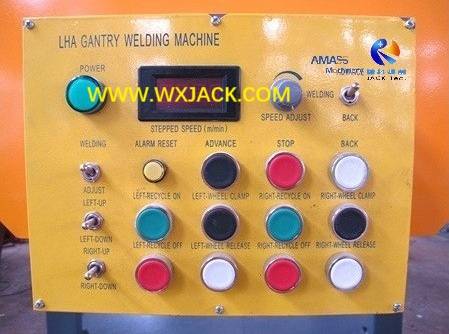

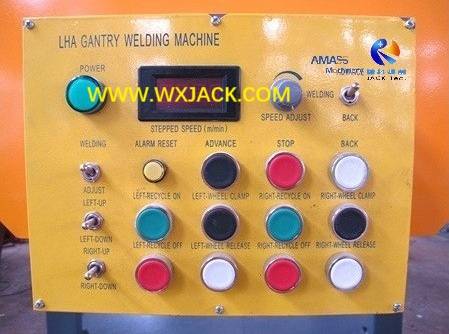

Operating panel of Wuxi JACK export LHA and LHT models machine: (Fig.5)

2) SAW Welding Speed Management in LHT H Beam SAW Welding Machine

This is controlled with A.C. inverter. Its working principle:

a) The A.C. inverter rectifies A.C. electricity into D.C. electricity;

b) Then inverts the D.C. electricity back into A.C. electricity of adjustable voltage and frequency;

c) The inverted A.C. electricity then powers A.C. motor, attaining purpose of smooth speed control in the machine;

3) During SAW welding operation, the A.C. inverter gives protection on motors against overload, over voltage, over current, and phase failure, etc.;

4) Also, it can execute on automatic compensation against voltage fluctuation, ensuring stable running of motor in the H Beam Gantry Welding Machine.

5. Technical Parameters of LHT Model H Beam Gantry Welding Machine:

LHT Model T Frame H Beam Gantry Welding Equipment |

Parameter | Specification | Note |

Operator Working Position | Beneath T frame, between 2 supporting racks, stand on the floor |

H Beam Flange Width (mm) | 200 ~ 800 |

|

H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

H Beam Web Height (mm) | 200 ~ 2000 |

|

H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

H Beam Length (mm) | 4000 ~ 15000 | Can be special made |

Gantry Travel Rail Length (mm) | 18000 |

|

Gas Pressure | 0.4 ~ 0.6Mpa

| For driving Arc tracing unit |

T Frame Drive mode | Double drive |

|