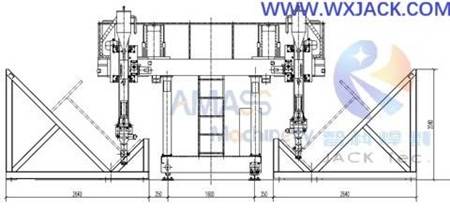

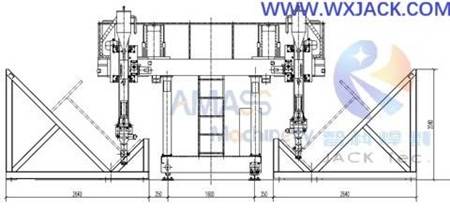

Background on Application: There are two sets of LHT T frame Gantry H Beam Welding Equipment produced by Wuxi JACK deployed in a row, in the first photo taken at customer facility. The workpiece output from it is shown in the second photo: Welding H Beam of designated size. Its design structure is as below: (Fig.1)

1. Working Complex in LHT I H Beam Gantry Welding Machine:

1) This automatic Gantry I Beam Welding Machine (H Beam) of submerged arc welding is a comprehensive system integrating management of outsourced components into one machine control;

2) Conceivably, quality of these purchased units plays an important role in quality assurance of the LHA model gantry structure machine, LHC model column type machine, and LHT model T frame machine;

3) We give introduction on SAW power source of HUAYUAN and Lincoln brand in the product section of “45° Fillet Welding LHA Series” and “LHC Column type” respectively;

4) Function Units: Besides it, another important outsourced component is used in the H Beam SAW Machine is Welding Flux Recovery and Recycling unit, which affects on SAW welding quality and running cost in large degree. For this unit we choose Chinese brand, to be specifically, Wuxi local supplier of LIANTONG product. We will have an introduction on it in the next segment.

2. Welding Flux Recovery and Recycling Unit in LHT H Beam Gantry Welding Machine:

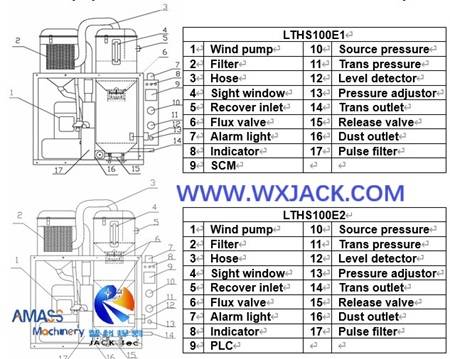

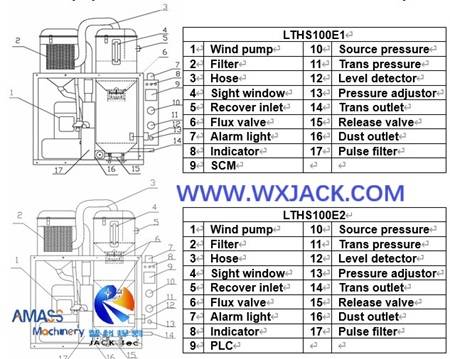

This is the introduction on welding flux recovery and recycling unit used in our column type, T type, and Gantry structured H Beam Submerged Arc Welding Machine: (Fig.2)

1) Brief on Welding Flux Recovery and Recycling Unit:

LTHS-E-type welding flux recovery and recycling unit can be used as assisting mechanisms for all kinds of welding process, which involve recycling welding flux for use, such as submerged arc welding;

2) Formation of Welding Flux Recovery and Recycling unit used in H Beam Gantry Welding Machine: (Fig.3)

a) This unit is composed of main body of the welding flux recovery unit, flux hopper, stainless steel pipe, connection hose and suction tip;

b) Its flux hopper is installed on the front side transverse beam of the T type, column type and gantry H Beam Welding Equipment, the main body on the top of frame in these machines;

c) Suction tip is installed on the front end of welding torch: (Fig.4)

d) Connection among mechanical main body, welding flux hopper and suction tip in this unit is by way of stainless steel tubes and hoses;

e) In this way, it forms a complete set of automatic flux circulating, transmission and recovery system, applied in series of the machines;

3) Working Principle of Flux Recovery and Recycling Unit in H Beam SAW Welding Machine:

a) The working of the flux recovery and recycling unit is controlled with PLC - Programmable logic controller;

b) By means of two pneumatic valves, the storage bucket is divided into three sections of recovery bucket, transition bucket and feeding bucket;

c) During welding process of the LHT T frame, LHC column and LHA gantry H Beam SAW Welding Machine, welding fluxes are sent from recovery bucket into feeding bucket by way of transition bucket, without necessity of shutting off the whole unit;

d) When flux volume inside the feeding bucket becomes less than 15kg, the recovery unit will send alarm, so that the entire system will always work normally during SAW process;

4) For more details on installation, operation and maintenance of the welding flux recovery and recycling unit installed in the LHC column style, LHT T style, and LHA Gantry structured machines produced by Wuxi JACK, customer can check on the manual and diagram of the unit, together with other technical documents delivered with the machine.

3. Technical Parameters of LHT H Beam Gantry Welding Machine:

LHT Gantry H Beam Submerged Arc Welding Machine (H Beam SAW Welding Machine) |

Parameter | Specification | Note |

Operator Working Position | Beneath T frame, between 2 supporting racks, stand on the floor |

Fitting H Beam Flange Width (mm) | 200 ~ 800 |

|

Fitting H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

Fitting H Beam Web Height (mm) | 200 ~ 2000 |

|

Fitting H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

Fitting H Beam Length (mm) | 4000 ~ 15000 | Can be special made |

Gantry Travel Rail Length (mm) | 18000 |

|

Gas Pressure | 0.4 ~ 0.6Mpa | For driving Arc tracing unit and flux recovery unit |

Welding Flux Recovery and Recycling unit Quantity | 2 sets | Equipped with SAW power source one set each |

Welding Flux Recovery and Recycling unit Capacity | 50 kg |

|

Welding Flux Recovery and Recycling unit Alarm Threshold | 15 kg |

|