Feature in Application: Compared with LHA gantry structure and LHC column structure gantry moving models, the LHT T structure H Beam Gantry Welding Machine has capability of producing larger size H Beam: As you can find from attached photos, the workpiece laid on supporting rack is not confined with the T frame of this machine: No limitation:

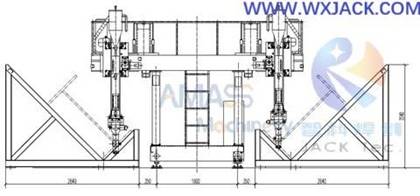

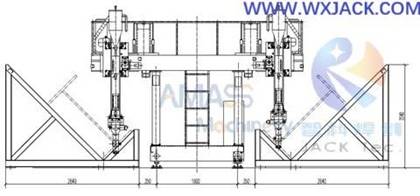

Design sketch on LHT and its way of laying H Beam on its rack: (Fig.1)

1. Topics on LHT, LHA and LHC Gantry I Beam Welding Machine:

1) 3 Major Types of I H Beam submerged arc welding Machine:

a) LHA series (LHAZ and LHAC sub-division) gantry structure;

b) LHC model column type;

c) LHT model T frame;

2) Discussion on Gantry I Beam Welding Machine:

a) Outline on function and usage;

b) Structure, composition, advantage and disadvantage of each model;

c) Common points and difference among models of machine;

d) SAW welding modes and process control parameters;

e) Operation, operating panel, maintenance and service on machine;

f) Introduction on Wuxi JACK self made components, parts of the machine;

g) Major outsourced Units: SAW welding power source, SAW welding flux recovery and recycling machine, A.C. inverter);

h) Installation, adjustment and daily service on the H Beam Gantry Welding Machine, etc.

2. Complements on Introduction of H Beam Gantry Welding Machine:

1) Arrangement of Cables in the gantry I Beam Welding Machine:

As a machine with frequent to and fro movement of mechanical frame during its SAW welding operation, proper laying of cables is very important:

a) For those involved with movement of the T frame, the cables are deployed with overhead hanging rack alongside the rails;

b) For those involved with movement along transverse beam of T frame, the cables are deployed with drag chain;

c) Please check below picture marked in red color square frame:

At both sides lateral of machine, hanging cables for flexible movement: (Fig.2)

2) For the purpose of easy maintenance on the LHT (LHC and LHA models also) machine, there is platform on the top of frame, surrounded with guard rail, and accessed with ladder. Please check below picture, marked in red color square frame:

Maintenance onto top platform of machine frame by way of climbing ladder: (Fig.3)

3) For the purpose of got informed the very first time when contingency happens, there is an alarm light fit at top of the Gantry I Beam Welding Machine, very eye catching, Please check the above picture, marked in red color square frame also;

4) For Operators of LHT (LHC and LHA) Gantry H Beam SAW Machine:

a) Before operating the machine, operator should read and understand manual book, being familiar with structure, operation and adjustment, has the capability on proper operation and monitor on running of the machine;

b) Operator should have trial run first;

c) Being familiar with all the pushbuttons and switches on operating panel and pendant;

d) Confirm all units of the machine are in normal state;

e) Make adjustment on welding parameters of the SAW power supply.

In all, make good preparation on SAW welding process in the machine;

5) As summary, we expect that with these 22 models of the H Beam submerged arc welding machine, together with special made ones, we can provide optimum solution for customers with the best fit.

3. Technical Parameters of LHT Model H Beam Gantry Welding Machine:

LHT model I Beam Submerged Arc Welding Equipment (H Beam SAW Machine) |

Parameter | Specification | Note |

Operator Working Position | Beneath T frame, between 2 supporting racks, stand on the floor |

H Beam Flange Width (mm) | 200 ~ 800 |

|

H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

H Beam Web Height (mm) | 200 ~ 2000 |

|

H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

H Beam Length (mm) | 4000 ~ 15000 | Can be special made |

Gantry Travel Rail Length (mm) | 18000 |

|

Gas Pressure | 0.4 ~ 0.6Mpa | For driving Arc tracing unit and flux recovery unit |

Submerged Arc Welding type | 45° fillet welding |

|

Submerged Arc Welding mode | Single Arc, Or Tandem Arc |

|

Welding Power Source brand and model | Chinese HUAYUAN or U.S.A Lincoln | ZD7-1000 or DC-1000 |

SAW Welding Speed (mm/min.) | 240 ~ 2400 |

|

Idle Speed (mm/min.) | 3200 |

|