1. Working Manner of LHC Column H Beam SAW Welding Machine in Automatic Line:

Working as one of the core equipment in an automatic H Beam production line, the LHC model is a typical automatic Column I Beam Submerged Arc Welding Machine (I Beam is synonym of H Beam) in terms of:

1) Machine control and operation;

2) Workpiece H Beam feeding in, flipping and sending out;

3) Linkage control with other H Beam Production machine in the line.

2. Uniqueness of LHC Column H Beam Gantry Welding Machine:

Sharing the same SAW (Submerged arc welding) welding mode and equipment with LHT and LHA models gantry type machine, the LHC model has its obvious uniqueness on the aspect of:

1) Major frame structure --- The one side working overhanging trolley compared with double side working gantry frame in LHT and LHA models equipment:

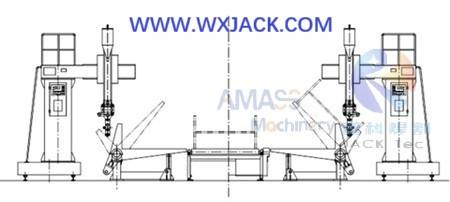

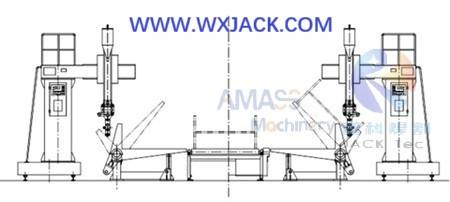

Design print on layout of 2 sets of LHC in automatic H Beam line: (Fig.1)

2) Quantity of welding unit --- One set in LHC model machine, versus two sets in the case of LHA gantry frame and LHT models T frame H Beam Welding Machine);

3) Therefore Productivity on H Beam SAW --- At any moment, one piece of H Beam is welded in LHC model, compared with two pieces of H Beam can be welded simultaneoulsy in LHA and LHT models machine.

3. Technical Aspect of LHC Model Column H Beam Welding Machine:

Supplement on LHC model machine:

1) Electric Control board of LHC Column H Beam SAW Welding Machine:

Compact design: Machine control cabinet is put inside column of the motor drive moving trolley, which means it is invisible from outside. This is different from LHA and LHT model machines. Such kind of design can make machine body of LHC model machine has plain, open and shut structure:

Electric control board (Inside upright column) and operating panel of Wuxi JACK LHC H Beam Welding Machine: (Fig.2)

2) Rail Span of LHC Column H Beam Welding Machine:

This specification in LHC model is far less than in LHA and LHT models: 1150mm of rail span in LHC model, compared with 4,000 ~ 5,500mm in LHA and LHT models. This is determined by specialty of its mechanical frame structure;

3) Rail Length of Standard LHC I Beam Submerged Arc Welding Machine:

a) In LHC model column structure machine, It is 3,000mm shorter than in LHA and LHT models: 15m rail lengt in LHC, versus 18m rail length in LHA and LHT models machine, and hence finished H Beam length produced shorter (12m versus 15m);

b) Of course, this specification can be special made;

4) Interlock Control of LHC Column H Beam SAW Welding Machine:

a) Interlock with 90° /180° Overturning rack and steel conveyor at the front of and back of each set of LHC column structured machine is realized with pushbuttons and switches integrated on its operating panel (LHC);

Operating panel of Wuxi JACK export LHC machine: (Fig.3)

b) This means, working as part of an automatic H Beam Production line, LHC model machine not only has function of control itself, but also that of auxiliary equipment of the line;

4. Welding Arc Tracing Unit Applied in LHC Column H Beam Welding Machine:

Mechanical pneumatic drive welding arc tracker in Wuxi JACK machine: (Fig.4)

1) This is designed and produced by Wuxi JACK engineering and production team. It is a detecting and tracing unit for managing on SAW welding process during H Beam production;

2) This unit is mechanical type, for controlling movement of welding torch in three axis(X, Y, Z). Please check the above picture on its structure;

3) Motion control on Arc Tracing Unit of H Beam SAW Welding Machine:

a) The vertical direction is pneumatic type (driven with air cylinder);

b) Horizontal and revolving direction is floating type;

4) Role of Welding Arc Tracing in H Beam Gantry Welding Machine:

This unit makes welding torch of the welding torch aiming at welding seam throughout the entire welding process:

a) When welding seam deflects leftward or rightward, the welding arc tracing rack will adjust on automatically along the transverse carriage of the machine under action of spring;

b) When welding seam deflects up and down, control roller will adjust welding torch along vertical direction by means of air cylinder.

5. Technical Parameters of LHC Column H Beam SAW Welding Machine:

LHC Column I Beam Submerged Arc Welding Machine |

Parameter | Specification | Note |

Operator Working Position | Stand on moving trolley of column body |

Proper H Beam Flange Width (mm) | 200 ~ 800 |

|

Proper H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

Proper H Beam Web Height (mm) | 200 ~ 2000 |

|

Proper H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

Proper H Beam Length (mm) | 4000 ~ 12000 | Can be special made |

Gantry Travel Rail Length (mm) | 15000 | Can be special made |

Rail Span | 1150 |

|

Trolley Travel drive mode | Double drive |

|

Trolley Welding travel speed (m/min.) | 0.24 ~ 2.4 | Controlled with Inverter |

Trolley Idle travel speed (m/min.) | 3.2 | Constant |

Welding Unit quantity (Welding power supply, torch, arc tracer, wire feeder) | 1 set |

|