Background: The attached photos record on the working moment of Wuxi JACK LHC model Column H Beam Welding Machine, working in automatic H Beam Production Line.

1. Usage of LHC Column I Beam Gantry Welding Machine:

Task and Operation Mode: The LHC model column I Beam Submerged Arc Welding Machine is used in heavy duty automatic H Production Line, in the form of four sets deployed together, forming into SAW zone, for carrying out SAW welding H Beam, with its web width up to 2,000mm (currently one of the biggest dimensions in steel structure industry) in automatic way:

At Russian customer facility: 4 sets of Wuxi JACK LHC model machine, operate in SAW zone of automatic H Beam Production Line: (Fig.1)

2. Process Technology on Welding H Beam with LHC Column I Beam SAW Machine:

As introduced in process technology of H Beam Automatic Production Line, the four sets of LHC model machine are divided into two groups:

1) Division: The first group of two sets of LHC model machine work in the first welding area, and the second group of two sets in the second welding area;

2) Logistic Equipment in Automatic Line: The flipping and transport of H Beam among the four sets of the LHC Column H Beam Welding Machine (or, to be more precisely, between the first and second welding areas) is accomplished with 90° and 180° Overturning Rack as well as steel conveyor, without human intervention;

3) Steamline on Welding: In this way, the four pieces of welding seams on a piece of H Beam can be welded in a stream line with the going through the four sets of LHC model machine.

3. Composition of LHC Column H Beam Welding Machine:

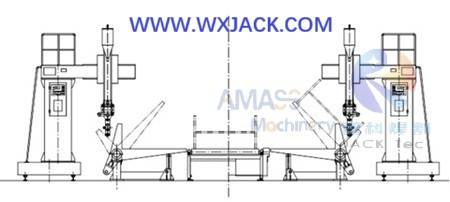

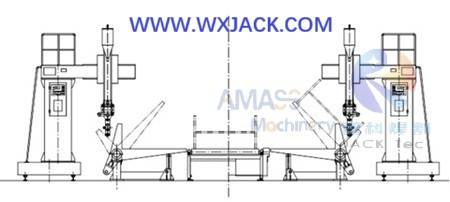

Please check below sketch for part of main components marked (Two sets of LHC are put face to face):

Design sketch on LHC machine deployment in automatic H Beam Production Line: (Fig.2)

One set of this LHC Column I Beam SAW Machine is composed of:

1) Mechanical Frame: Motor drive moving trolley, column, overhang beam, (these three units are assembled as an integral machine body of the LHC machine);

2) SAW Welding Function Group: Transverse carriage and welding torch units, as well as welding arc tracer and welding wire feeder, being installed on the welding torch (This section is installed on the beam of the LHC machine body):

Mechanical frame and SAW group of Wuxi JACK LHC model machine: (Fig.3)

3) Drive and Transmission: Motor and travel reducers, for driving trolley movement in welding speed, and welding carriage movement respectively;

4) Welding System: SAW Welding power supply, welding flux recovery and recycling unit (one set each) equipped with the LHC machine;

5) Pneumatic system (for driving welding arc tracer unit);

6) Electric control system, control board, operating panel, cable drag chain, cable hanging rack of the LHC Column I Beam SAW Machine.

4. Main Trolley Movement of LHC Column H Beam Welding Machine during Working:

1) Adjustable SAW Welding Speed: LHC Column structure machine uses moving trolley as its main frame for working. Same as gantry type LHA model, moving speed of LHC trolley is controlled with A.C. inverter (SAW welding speed) during welding operation:

Trolley of LHC moves along H Beam, and carry out welding at the same time: (Fig.4)

2) Double drive in Trolley Traveling of LHC Column I Beam SAW Machine:

a) There are two sets of motors driving gears into revolve by means of two motor reducers, which in turn drive the two pieces of shafts;

b) In this way, the double drive style of double shafts and four wheels (the wheels are fit at the bottom of the trolley and move along the rail) can avoid crawling issue caused from skidding, making sure the trolley running in stable and reliable manner, during the entire SAW welding process of the LHC column structure machine;

3) Adjustment on SAW Speed: During SAW welding, trolley moving speed, which is also the SAW welding speed of the LHC machine, is set with turning knob on the operating panel of the LHC Column I Beam Welding Machine, based on H Beam flange and web thickness to be welded, as well as welding current and voltage of SAW power supply needed, within the range of 240~ 2,400mm/min. (continuous adjusting). This is also true with T style LHT and LHA gantry structure machine also:

Welding speed turning knob and digital display on operating panel: (Fig.5)

4) Trolley Idle Movement: When not in work, the trolley move in idle high speed of 3,200mm/min., to retreat to its starting point for next round of welding operation.

5. Technical Parameters of LHC Column I Beam SAW Machine:

LHC Column I Beam Gantry Welding Machine (I Beam Submerged Arc Welding Machine) |

Parameter | Specification | Note |

Operator Working Position | Stand on moving trolley of column body |

Fitting H Beam Flange Width | 200 ~ 800 mm |

|

Fitting H Beam Flange Thickness | 6 ~ 40 mm | Can be special made |

Fitting H Beam Web Height | 200 ~ 2,000 mm |

|

Fitting H Beam Web Thickness | 6 ~ 32 mm | Can be special made |

Fitting H Beam Length | 4,000 ~ 12,000 mm | Can be special made |

Gantry Travel Rail Length | 15,000 mm |

|

Trolley Welding travel speed | 240 ~ 2,400 mm/min. | Controlled with Inverter |

Trolley Idle travel speed | 3,200 mm/min. | Constant |