Background: The attached 6photos were taken on a set of Wuxi JACK LHA4C model Gantry H Beam Welding Machine, which was exported to India in 2017.

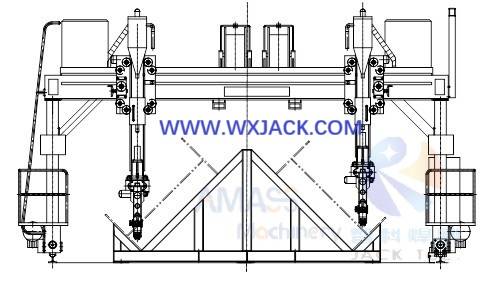

Design print on LHA model machine: (Fig.1)

1. Application of LHA4C H Beam Gantry Welding Machine in welding H Beam Production Process:

1) Workpiece Specification Compare: For the H Beam with its max. web height of 1,500mm, the LHA4C Gantry H Beam SAW Machine does not have counterpart in center control structure machine: The largest workpiece size in LHA4Z model is 1,200mm, and LHA5Z is 1,800mm;

2) On the other hand, in all the process step of H Beam production Line, 1,500mm is one of the standard indexes in terms of max. web height, and also the most used one, due to its medium size. For this specific model of LHA4C machine, the corresponding suitable H Assembly machine is Z15, and H Beam Straightening Machine is HYJ800 or HYJ40.

2. Strong Points of LHAC Side Control H Beam Gantry Welding Machine in Operation:

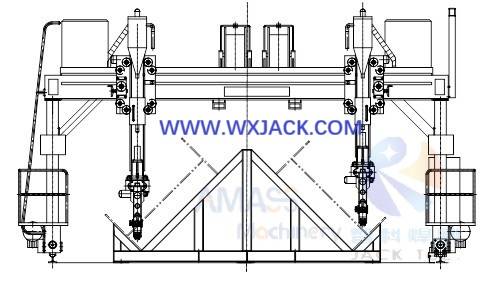

Number of Operators involved in Operation: Judging on the surface, as a side control machine (Operators stand at external side of H Beam at the outside of machine rail, please check below sketch), this series of automatic Gantry H Beam SAW Machine has the “drawback” of needing two operators to manage on the SAW (Submerged arc welding) of two workpieces, instead of only one operator:

Need 2 operators to work on side control LHAC model: (Fig.2)

However, as a saying goes “Anything existing must be reasonable”, with such kind of arrangement in the LHAC model machine, it has several merits, which is important for customer:

1) Land Occupation of Side Control LHAC H Beam Gantry Welding Machine:

As explained before, for the same size of H Beam web height, LHAC model machine is more compact than LHAZ in terms of machine size (10% less);

2) Welding Quality Assurance in LHAC Side Control Gantry H Beam SAW Machine:

a) With each operator takes care on each piece of H Beam welding, he or she does not need to distract attention from this H Beam to the other during the simultaneously two H Beam SAW process. Which means, the operator can focus on the welding of specific H Beam whole heartedly, and thus can deliver welded H Beam of high quality in greater probability from side control models machine;

b) Anyway, as introduced in product category of these series of high quality Gantry I Beam Submerged Arc Welding machine (LHAZ, LHAC, LHC, LHT models), submerged arc welding is the most important step for in H Beam production process technology, in terms of finished product quality control;

3. Working Process Management in LHAC Gantry H Beam Welding Machine:

Also, because two operators work at the same time, they can manage on working process of this high efficiency gantry machine more easily and calmly than in the case of central control type machine:

1) Work as Team: Cooperate and act as each other’s back up. When any one of the operators needs to leave working site in a short time during working period, the other operator can substitute his or her job immediately;

2) Overall Management: Monitor SAW process of the two H Beam in the gantry H Beam Welding Machine together. If one operator has an absent mind at certain time, the other operator can make up for the ignorance;

3) If ever contingency or problem happens with the machine running site, they can deal with the condition without in a hurry.

4. Interlock Operation in LHAC Side Control H Beam Gantry Welding Machine:

1) On the other hand, with two operators operate on this LHAC automatic H Beam SAW machine together, synchronous work is very important. Otherwise, suppose such a situation, that one operator starts on welding process of one welding torch, while the other does not start on the other one…

2) For this reason, in electric control system of this side control HA4C model machine, there is interlock between the two welding stations (Welding torch mechanisms) in the machine. Which means, as in the above mentioned case, only two operators start the SAW welding power supplies together, can begin the process of gantry travel and SAW in the entire set of LHAC side control machine.

5. Technical Parameters of LHA4C Side Control Gantry H Beam SAW Machine:

LHA4C Gantry H Beam Welding Machine (Gantry I Beam Submerged Arc Welding Machine) |

Parameter | Specification | Note |

Operator Working Position | Both sides of Gantry, external sides of supporting racks |

H Beam Flange Width | 200 ~ 800 mm |

|

H Beam Flange Thickness | 6 ~ 40 mm | Can be special made |

H Beam Web Height | 200 ~ 1,500 mm |

|

H Beam Web Thickness | 6 ~ 32 mm | Can be special made |

H Beam Length | 4,000 ~ 15,000 mm |

|

Gantry Span | 4,000 mm |

|

Gantry Travel Rail Length | 18,000 mm |

|

SAW Welding Speed | 240 ~ 2,400 mm/min. | VFD |