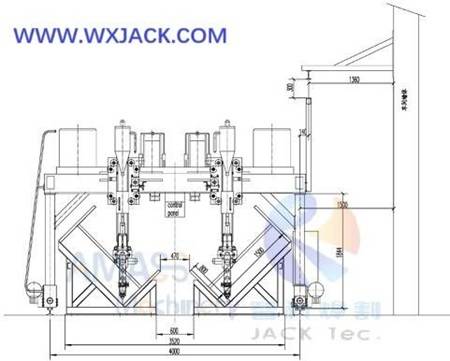

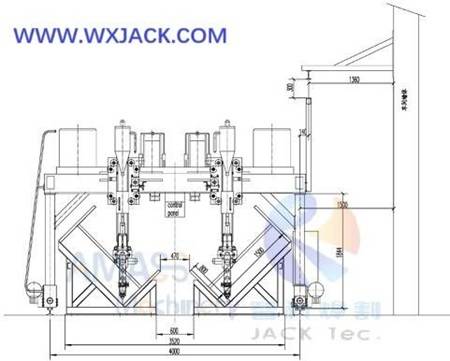

Importance of Machine: LHA series Gantry type H Beam Submerged Arc Welding Equipment has wide application in steel structure industry. The attached 6 photos show various sizes and configurations of such LHA models machine being put into use at customer site and Wuxi JACK facility. It is sketch is as below:

Mechanical main frame of LHA machine: (Fig.1)

1. Main Working Cells of LHA Series H I Beam Gantry Welding Machine:

The LHA models gantry type machine is a kind of fully automatic equipment, for acquiring on H I Beam submerged arc welding, integrating manipulation of below into one single set of machine:

1) SAW Main Machine --- By way of machine operating panel;

2) Two sets of SAW power supply --- By way of its own control console and operating panel of the LHA model machine;

3) Two sets of SAW welding flux recovery and recycling unit--- By way of operating panel of this LHA model machine;

4) Two sets of SAW wire feeder --- By way of operating panel of this LHA series gantry type machine;

5) Two sets of arc tracing unit --- Mechanical type, no need to have manual manipulation during SAW welding in the LHA H Beam Welding Machine;

Into a convenient and easy operation. One operator can manage all these working cells.

2. Deployment of Main Working Cells in LHA Series Gantry type H Beam Welding Machine:

The abovementioned manipulation of all function units is realized under the condition of, these components are deployed at different specific sections inside this large overall dimension equipment:

1) SAW power supplies are put on the workshop floor alongside the long parallel traveling rails, in fixed manner;

2) Together with its hoppers, welding flux recovery and recycling units are put on the top side of beam of the gantry, and move along together with gantry moving during welding process of the H Beam Welding Machine;

3) Welding wire feeders and welding arc tracing units are assembled with SAW welding torch, composing into a complete set of SAW welding unit, which is fit on the transverse moving carriage of this LHA model gantry type I Beam SAW Machine. And each set of the carriage is installed on the beam of the gantry frame, at its front side.

To give a clear introduction, please check below picture:

Front view on Wuxi JACK LHA machine at customer workshop: (Fig.2)

3. Operation Management for Work of LHA Model I Beam Gantry Welding Machine:

1) Control of this LHA Gantry type H Beam Submerged Arc Welding Equipment (also LHC and LHT) is realized with “One Button Starting on and Shutting off the entire Machine”;

2) Which means, with the “WELDING ON” button being pressed on the operating panel of this LHA model H Beam Welding Machine, the machine itself and all the above mentioned auxiliary welding function units will be started on for working together, or shut off for break together. Please check attached sketch on machine operating panel of the LHA model machine exported to Russia:

Russian language operating panel of Wuxi JACK exported to Russia LHA model H Beam welding equipment: (Fig.3)

3) Same as LHT series I Beam Gantry Welding Machine, electric control board of LHA model is put on bed of mechanical gantry frame, at its lateral side. Please check below picture. Such arrangement has advantage of concise and short distance cable routing in the entire machine, as well as playing as counter weight to give double insurance against the gantry frame from toppling down (although this is very low probability):

Electric control board of LHA machine and its laying position: (Fig.4)

4) Supplementary Notes on H Beam Welding Machine:

a) For the other kind of common used model besides LHA and LHT: The column structure LHC model, please check product section of “LHC Column type”;

b) For understanding on specific model of LHA models machine as an example, please check product section (Or other section) of “4m Rail Span LHA4Z Automatic machine”.

4. Technical Parameters of LHA Model Gantry type H Beam Welding Machine:

LHA Model Gantry type H Beam Submerged Arc Welding Equipment I Beam Gantry Welding Machine |

Parameter | Specification | Note |

Operator Working Position | Beneath the gantry, at internal sides of supporting racks for LHAZ, and external sides for LHAC |

H Beam Flange Width (mm) | 200 ~ 800 |

|

H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

H Beam Web Height (mm) | 200 ~ 1,200/ 1,500/ 1,800/ 2,000 | Varies on models |

H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

H Beam Length (mm) | 4000 ~ 15000 | Can be special made |

Gantry Span (mm) | 4,000/ 5,000/ 5,500 | Varies on models |

Gantry Moving Rail Length (mm) | 18,000 |

|

SAW welding speed (mm/min.) | 240 ~ 2,400 | VFD (Variable Frequency Drive) |

Idle speed (mm/min.) | 3,200 |

|