The attached is a set of Wuxi JACK PHJ18 model 3 in 1 H Beam Fabrication Machine, which is being installed at a Chinese customer site ready to be put into use.

A. Outline on PHJ18 Fit Up Full H Beam Fabrication Machine:

1. Origin and Specifications of PHJ18 Model 3 in 1 H Beam Assembly Weld Straighten Integrated Machine:

1) PHJ18 is supplement on PHJ15 model, for making larger workpieces of welded H Beam and T Beam;

2) The models share similar structure, but have 300mm web height difference both in machine dimension and workpiece size;

1) PHJ18 is suitable for producing light and medium duty welded H Beam and T Beam of weight less than 8 Ton;

2) The finished fabricated welding seam on produced H Beam has size less than 12mm --- This is the threshold for dividing between heavy duty and medium and light duty H Beam. The former should be manufactured with heavy duty H Beam Production Line;

3. Huge Variable Labor Cost Save from PHJ18 Model 3 in 1 H T Beam Welding Machine for Customers:

1) With the introduction of PHJ series machine, the original 6 operators necessary for making H Beam:

---2 Operators for running Z15/ Z18/ Z20 models H Beam Assembly Machine;

--- 2 Operators for running LHC/ LHA/ LHT series H Beam Submerged Arc Welding Machine;

--- 1 Operator for running HYJ/ YTJ series H Beam Straightening Machine;

--- 1 Operator for supporting on inter-station transshipment

2) Now reduced to one veteran staff and a part time assistant;

3) In this sense, PHJ series machine is a revolutionary product for in steel structure industry.

B. Technical Illustration on PHJ18 Model 3 in 1 H Beam Fabrication Machine:

1. Operating Station of 3 in 1 H T Beam Welding Machine:

1) Layout: As can be checked from attached picture, the electric control board/ pump station, and SAW power supply are located alongside mechanical main body of the machine, leaving an aisle for passing through workpieces;

2) The SAW power supply has red color, it should be Lincoln DC-1000;

3) This constructs a working zone for the machine;

1) The attached 1st photo was taken at front side of the machine, which has same orientation as that of the 4th photo;

2) The attached 4th photo is the dedicated machine area at Wuxi JACK company;

3) The 2 photos display on workpiece (Welded H Beam) going out side of the machine, which is the straightening unit;

1) The attached 2nd picture was taken at sub-assembling area of Wuxi JACK;

2) There are several sets of mechanical base bed going under assembling here;

3) Base bed is the central working area in a set of PHJ series machine, which integrates assembling/ welding/ straightening units of this 3 in 1 Pull Through H Beam Welder machine;

4) As can be seen from the photo, assembling and straightening has the same set of motor for drive and transmission, which are connected together in phase with chains and sprockets at left external side of the base bed;

5) PHJ series machine has its main driving and transmission system installed at outlet side of mechanical main body (Straightening side);

4. Commissioning on 3 in 1 H Beam Assembly Weld Straighten Integrated Machine:

1) The attached 3rd photo was taken at commissioning area of Wuxi JACK;

2) A set of assembled and painted PHJ18 model was fabricating on a piece of T Beam;

3) This photo was taken at the rear side (Material incoming side), or assembling side of the machine;

5. Packing on 3 in 1 H Beam Assembly Weld Straighten Integrated Machine:

1) The attached 5th photo records on packing process for a set of exported Wuxi JACK machine;

2) For a set of PHJ series machine, a container of 40GP should be used for its package and shipment.

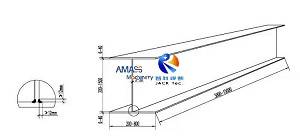

Finished welded H Beam to be produced from the machine: (Fig.1)

![0B- PHJ H Beam Welding Machine 0B- PHJ H Beam Welding Machine]()

3. Technical Parameters of PHJ18 Model 3 in 1 H Beam T Beam Welding Machine:

Technical Parameter | PHJ18 Multi-Function H Beam Welding Machine |

Web Height | 200 ∼ 1800 mm |

Web Thickness | 5 ∼ 30 mm |

Flange Width | 200 ∼ 800 mm |

Flange Thickness | 6 ∼ 40 mm |

Workpiece (Welding H Beam) Length | 3000 ∼ 15,000 mm (Can be longer or shorter) |

Working Speed of Assembly/ Welding Straightening | Recommend 200 ∼1,200 mm/min. for ideal welding quality (Stepless, A.C. Inverter Control) |

Height of Single Pass Welding Seam | 8 ~ 12 mm |

Workpiece (Welded H Beam) Cross Section | Symmetric and Asymmetric Section Shape |

Overall Dimension of Machine(L×W×H) | 28m × 4m × 4.8m |

Conveyor | Input and Output 11m length each, 3 segments each; One driving, two followers Input conveyor with 3 sets of pulling rod box |

Driving Mode | Assembly/ Straightening: Hydraulic cylinders |

Welding Mode | Single Arc or Twin Arc SAW (Submerged Arc Welding, 2.5/ 3/ 4 mm diameter welding wire) at fillet flat position |

Operator | 1 ~ 1.5 (1.5 means a part time support) |