1. Outline on Application of Z15 Manual H Beam Assembly Machine:

1) The Working Nature of Manual I Beam Assembling Machine:

Feature: The Manual Alignment Manual Tack Welding Z15 is the “old fashioned” Manual H Beam Assembly and Tack Welding Machine, because of the two critical operations:

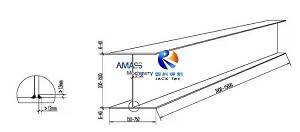

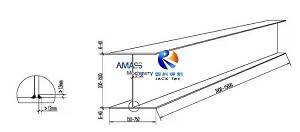

Finished H Beam produced from Z15 model machine: (Fig.1)

a) Alignment and fixing of the two pieces of flange and one piece of web (which is, H Beam assembly);

b) CO2 tack welding;

Are all performed manually. So, this series of product can be named as “Manual Machine”;

2) Demand on Operator of Manual H Beam Assembling Machine:

For delivering satisfactory WIP (working in process) welded H Beam from the machine, it is necessary to:

a) Two operators work together all the while (they stand at both sides of workpiece), first assembling the H Beam, then carry out manual tack CO2 welding on H Beam (And T Beam);

b) These two operators should have superb skill and rich experience on manual CO2 welding;

3) In this sense, this series of Z15/ Z18/ Z20 models Manual H Beam Assembly Machine with Tack Welding poses high demanding on operators’ capability;

4) Related Equipment for H Beam Production with I H Beam Assembly Machine:

Following the Z20 model machine, the next two equipment for manufacturing welding H Beam are:

a) SAW welding: LHA55Z or LHA5C H Beam Submerged Arc Welding Machine;

b) Flange Straightening: HYJ or YTJ series H Beam Straightening Machine.

2. Structure and Main Units of Z Series H Beam Assembling Machine with Tack Welding:

With this kind of machine with manual alignment and manual CO2 welding, being familiar with machine structure and components is vital important;

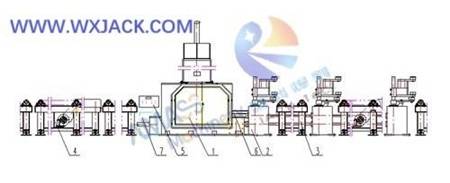

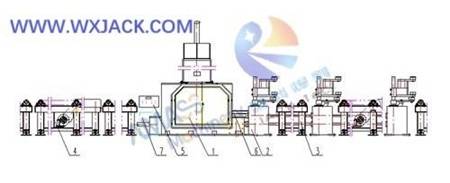

Design structure of Wuxi JACK machine with tack welding: (Fig.2)

1) The Z Series H Beam Assembly Machine with Tack Welding is composed of:

a) Mechanical main frame (Gantry with four pieces of rectangular rails fit);

b) Hydraulic drive pulling rod system (Hydraulic drive manipulator, two sets, for positioning of flange and web);

c) Input and output conveyor roller tables;

d) Hydraulic system: The assembling step in the machine is oil cylinder driven;

e) Electric control system;

2) Mechanical Main Frame of Wuxi JACK H I Beam Assembly Machine: (Fig.3)

Main Units: The mechanical main body is the basic frame of the machine, which is composed of top gantry, bed, platform, motor reducer, hydraulic system and control system;

3) Top Gantry of I H Beam Assembly Machine: (Fig.4)

a) This top gantry is composed of top beam, column, elevating beam, downward pressing roller, downward pressing cylinder;

b) Its main function in the machine is to press firmly H Beam web of various specifications against H Beam flange, during operation;

4) Machine Bed in the I H Beam Assembly Machine: (Fig.5)

a) Machine bed is composed of two pieces of wall boards and bottom beam, fit with arc guiding unit, web and flange clamping unit, main transmission system;

b) Its main function in the machine is to localize and clamp H Beam of various specifications, and carry out spot weld at the same time together with H Beam transport;

5) Motor Reducer in the machine: (Fig.6)

This unit drives main transmission roller by way of coupler. The reducer is individually from main body of the machine, easy for package and installation.

6) Mechanical Transmission System in the H Beam Assembly Machine:

a) Main transmission system of the machine is driven with motor reducer, which is joint with main transmission roller directly through coupler and transmission shaft;

b) Structure and Working Way: The two pieces of flange supporting rollers at the front and rear side of main transmission roller are driven with sprocket on the transmission shaft through chain, and rotate in phase with the main transmission roller:

Transmission mechanism of Wuxi JACK I H Beam Assembly Machine: (Fig.7)

7) For the further detail of each system of this Z15/ Z18/ Z20 series Welded I H Beam machine, please check next product section of Z18 and Z20 Manual Alignment model machine.

3. Technical Parameters of Z15 Manual H Beam Assembly Machine with Manual Tack Welding:

Model | Z15 Manual Alignment with Manual Tack Welding H Beam Assembly and Tack Welding Machine |

H Beam Web Height | 200 ~ 1,500 mm |

H Beam Web Thickness | 6 ∽ 32 mm |

H Beam Flange Width | 200 ∽ 800 mm |

H Beam Flange Thickness | 6 ∽ 40 mm |

H Beam Length | 4,000 ∽ 12,000 mm |

Max. H Beam Weight | 20 Ton. |

Web and Flange Alignment Style | Manual Alignment |

Tack Welding Style | Manual CO2 tack welding |

Operator | Two operators with skillful welding technique |

Conveyor speed (mm/min.) | 2000, constant |