Background: The Automatic H Beam Assembly and Tack Weld Machine in the first photo was taken on an automatic Wuxi JACK HB series H Beam Production Line exported to East Europe.

1. Application of Z15~ Z18 Automatic H Beam Assembly Machine:

1) Scope: Z15~ Z20 is a product group covering Z15, Z18, and Z20 models;

2) Purpose: For producing semi-finished workpiece of welded H Beam: Assembled and tack welded. The next equipment following the machine in the automatic H Beam Production Line is LHC H Beam Submerged Arc Welding Machine, as you can find from the first photo:

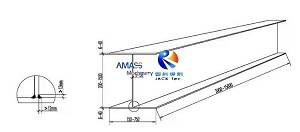

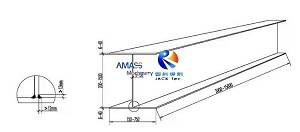

Welding H Beam fabricated: (Fig.1)

3) Product Group: Here Z15 ~ Z20 refers to product group of automatic machine with self alignment (Automatic assembly) and automatic CO2 tack welding, realized in the fashion of two sets of CO2 gas shielded welding power source, controlled with PLC and inverter in the electric control system of the H Beam Assembly Machine:

SAW power supply equipped with machine: (Fig.2)

GMAW CO2 welding power supply equipped with machine: (Fig.3)

2. Advantages of Automatic I Beam Assembly Machine:

As discussed in the previous section of Z15/ Z18/ Z20 manual operating mode machine, some of advantages with automatic machine are listed below but not limited to:

1) Labor Cost Saving: Operation of the automatic machine involves only one operator instead of two operators in manual machine;

2) Quality Assurance: Stable and consistent assembly and welding quality delivered compared with manual operation in the machine;

3) Requirement on Operator: Less requirement on skill and experience of operator than manual mode machine, so it is more easy to find eligible operators;

This is the reason nowadays automatic machine with tack welding takes more and more share in the field of H Beam production in Steel Structure industry.

3. Electric Control System of Automatic H Beam Assembly Machine:

Electric system controls machine operation, and achieves automatic working mode. Below is brief on electric system of the Z15/ Z18/ Z20 models automatic machine:

1) PLC in Electric Control System of H Beam Assembly Machine:

a) PLC is the core element of control system in the machine:

PLC in electric control system: (Fig.4)

b) PLC program controlling on H Beam fitting up is compiled on the basis of process technology of the H machine:

Process technology flow of H Beam assembly: (Fig.5)

c) PLC program is compiled on the basis of the above mentioned process flow in the automatic H Beam Assembly Machine;

d) Control Logic: During work period, PLC sends out command in the form of digital signal, controlling function elements acts accordingly, fulfilling tasks of positioning H Beam web and flange, FOR/ RVR of input and output drive conveyor, welding start, etc.;

e) Upgrade Conveniently: Change on machine control logic involves only compiling PLC program, instead of reworking or replacing hard wired relay circuit. This is the most conspicuous merit with PLC;

2) A.C. Inverter for Controlling Working Speed on H Beam assembly and tack welding: (Fig.6)

a) Working Way: Main drive motor, input and output drive conveyor of the automatic machine are all controlled with A.C. inverter, in unified adjustable speed;

b) Working Velocity Adjustment: There are eight sets of frequency are set in the A.C. inverter ahead of time (preset), corresponding with eight segments of required motor revolve velocity for the automatic machine;

c) Single Cycle Working Mode: When this Automatic H Beam Assembly Machine works under Single Cycle or Auto Cycle, output frequency of A.C. inverter is controlled with PLC;

d) Manual Working Mode: When this automatic machine works under Manual mode, output frequency of the inverter is controlled with a DIP switch on the machine operating panel;

e) Process Parameters: A.C. inverter used in these Z15/ Z18/ Z20 models Automatic H I Beam Assembly Machine has 0 ~ 400Hz output frequency range, 0.01Hz resolution, and consummate protection function;

f) Advantages: This makes sure that speed control of main drive and conveyor features in extensive range, smooth running and reliable work in the machine.

4. Technical Parameters of Z15 ~ Z20 Automatic H Beam Assembly Machine:

Model | Z15~Z20 Self Alignment Automatic H Beam Assembly and Tack Welding Machine |

H Beam Web Height | 200 ~ 1,500/ 1,800/ 2,000 mm |

Applicable H Beam Web Thickness | 6 ∽ 32 mm |

H Beam Flange Width | 200 ∽ 800 mm |

H Beam Flange Thickness | 6 ∽ 40 mm |

H Beam Length | 4,000 ∽ 12,000 mm |

Max. H Beam Weight | 20 Ton. |

Assembly and Tack Welding Velocity | 500 ~ 6,000 mm/min. |

Input and Output Conveyor Power | 2 x 1.1 kW |

Web and Flange Alignment Style | Self Alignment (Automatic), controlled with PLC and A.C. inverter |

Tack Welding Style | Automatic CO2 tack welding, ontrolled with PLC and A.C. inverter |

CO2 Gas Shielded Welding Power Source | Panasonic KR350 or HUAYUAN NB350 |

| Operator | 1 operator |