1. Application of Z series Automatic H Beam Assembly Machine:

1) Background: The attached first photo represents typical application site of Wuxi JACK machine group: Highly automatic H Beam Production Line;

2) Related H Beam Production Machine:

As you can find from the first photo, the other machines following the H Beam Assembly:

a) 90° Steel Structure Overturning Rack;

b) LHC H Beam Submerged Arc Welding Machine.

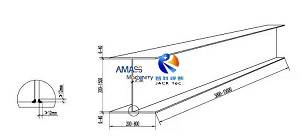

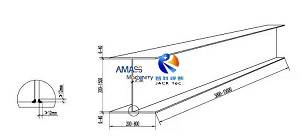

Cross section of finished welding H Beam: (Fig.1)

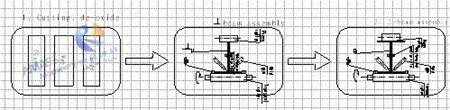

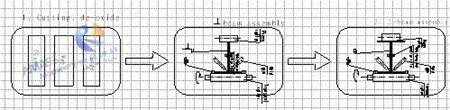

Process route of H Beam assembling and tack welding: (Fig.2)

2. Manual versus Automatic CO2 Welding in Automatic I Beam Assembly Machine:

1) Advantage of Automatic CO2 Welding in H Beam Assembly Machine:

Automatic H Beam assembly and tack welding operation: (Fig.3)

a) Raising Productivity: For producing the same size of H Beam, Automatic machine has 15% higher producing efficiency than that of Manual models equipment;

b) Advantages of Automatic Mode:

For these reasons, we recommend automatic mode machine to customer when they purchase this H Beam Production Machine, because of the below several reasons:

(1) Labor Cost Saving: One set of Automatic H Beam Assembly Machine needs only one operator to take care production process, instead of two operators in the manual mode machine;

(2) More Easy to Find Eligible Operator: Requirement on operator capability in manual mode machine is much more strict than operator of automatic equipment, in view of welding skill and experience;

(3) Quality Assurance: This H Beam Production Machine delivers finished H Beam with quality more stable and consistent than that of the manual equipment, so that less inspection work involved;

(4) Flexible on Process Technology Upgrade: More flexible in terms of control logic of the machine: For future expansion or update, because of PLC soft control, instead of hard wired relay circuit;

In this sense, from customer point of view, the Automatic H Beam Assembly Machine can pay for itself more quickly than manual equipment;

2) Advantage of Manual CO2 Welding in H Beam Assembly Machine:

Operator work on CO2 spot welding: (Fig.4)

a) Better utilization rate on CO2 welding power source: Customer can use the existing power sources of their own, instead of two sets of brand new as in the case of automatic mode machine;

b) Minimize Negative Affect of Mal-Operation: If there exists problem with PLC program, one batch of unqualified H Beam may have already been produced from automatic model machine, compared with possibly only one or two pieces in manual I Beam Assembly Machine: The loss is much less;

c) Single Mode First: This is the reason we suggest customer to have trial run in Single mode first before transferring to AUTO cycle, at initiation of H Beam assembly operation.

3. Hydraulic System in I Beam Assembly and Tack Welding Machine:

1) Importance of Hydraulic System in H Beam Assembly Machine:

a) Working Principle: From the perspective of control and power, the Z15 ~ Z20 models machine with Tack Welding is essentially controlled with electric PLC and A.C. inverter for its working logic management and speed control, and powered with hydraulic cylinder for its assembling job;

b) Importance: So, hydraulic system of the machine is of vital importance, as driving energy source of H Beam fitting up;

2) Composition of Hydraulic system in H Beam Assembly Machine:

Hydraulic pump station: (Fig.5)

a) Composition: In this machine, hydraulic system is composed of pump station, cylinders and piping;

b) Functions: In Z15 ~ Z20 models machine, downward pressing roller, web/ flange positioning and clamping unit, web/ flange terminal alignment unit, pulling rod system, arc guiding unit are all controlled with hydraulic system;

c) Start Up Way: Downward pressing roller, alignment unit and arc guiding unit are all started with hydraulic cylinder directly;

d) Advantage: The hydraulic cylinder for driving the downward pressing roller has long stroke;

e) Extension Shaft: To cater for pressing down H Beam web of various specifications, usually it is necessary to add an extension shaft at the front end of piston rod of the oil cylinder.

4. Technical Parameters of Z15 ~ Z20 Automatic H Beam Assembly Machine:

Model | Z15~Z20 I Beam Assembly and Tack Welding Machine |

H Beam Web Height | 200 ~ 1500/ 1800/ 2000 mm |

H Beam Web Thickness | 6 ∽ 32 mm |

H Beam Flange Width | 200 ∽ 800 mm |

H Beam Flange Thickness | 6 ∽ 40 mm |

H Beam Length | 4000 ∽ 12000 mm |

Max. H Beam Weight | 20 Ton. |

Hydraulic Motor Power | 4 kW |

Hydraulic Rated Pressure | 6 ~ 8 MPa |

Hydraulic Oil Pump Capacity | 24 L/min. |

Working Mode | Manual/ Single/ Auto |

Web and Flange Alignment Style | Self Alignment (Automatic), logic controlled with PLC |

Tack Welding Style | Automatic CO2 tack welding controlled with PLC and A.C. inverter |

CO2 Gas Shielded Welding Power Source | Panasonic KR350 or HUAYUAN NB350 |

Operator | 1 operator |

Assembly and Tack Welding speed | 500 ~ 6000 mm/min. |