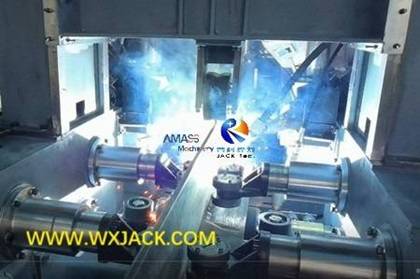

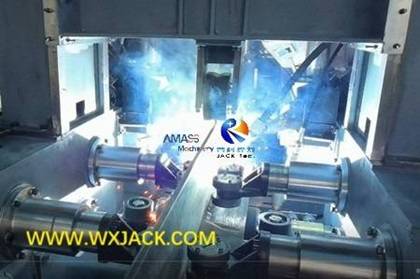

Background: The close up view on Z20 model automatic machine in the attached first photo reflects the detailed structure of the equipment main body.

1. The Application of Z20 Automatic H Beam Assembly Machine:

1) Model: Z20 is the largest model of Automatic H Beam Assembly and Tack Welding Machine, delivering assembled and tack welded H Beam with web height 2000mm:

Sketch on finished H Beam: (Fig.1)

2) Task of Z20 Large H Beam Assembling and Tack Welding Machine:

Working together with:

a) LHA55Z or LHA5C H Beam Submerged Arc Welding Machine;

b) HYJ and or YTJ series H Beam Straightening Machine;

The three machines including the first step of Z20 Automatic machine produces large size and heavy duty H Beam (Welding seam with 12mm height above);

3) Related Equipment: Correspondingly, Wuxi JACK produces another kind of three in one H Beam Assembly Welding Straightening Machine, for producing light duty and medium duty H Beam. The counterpart of Z20 automatic machine in this product family is ZHJ20 model H Beam Fabrication Machine:

Wuxi JACK ZHJ20 model H Beam Fabrication Machine: (Fig.2)

2. Automation of Z Series Automatic H Beam Assembly Machine:

With the working mode of manual CO2 welding, this series of H Beam Assembly Machine is still labeled as “Automatic”, because the machine is a kind of complicated control equipment, integrating the tasks of:

1) Workpiece feed in, send out and 180° flipping in Wuxi JACK H Beam Assembly Machine: (Fig.3)

2) Workpiece held upright from its falling down during working of Wuxi JACK machine: (Fig.4)

3) Workpiece positioning, alignment, clamp and assembly in Wuxi JACK machine: (Fig.5)

4) Workpiece CO2 welding in Wuxi JACK H Beam Assembling and Tack Welding Machine: (Fig.6)

Into single set of the equipment. All these are manipulated with the control system of the automatic machine.

3. Automatic Assembling Operation in Z Series H Beam Assembly Machine:

Especially the flange and web self alignment process, which is the precise assembling job in the automatic machine. To give clear illustration on it, please check the two pictures as below:

1) The Fine Assembling unit in Wuxi JACK automatic machine: (Fig.7)

From this picture, we can observe the web alignment and clamping rollers (inside the red color square frame) of the H Beam Assembling Machine:

a) Two groups of alignment rollers in one set of the machine, front side and back side each;

b) For each group, there are two pairs of alignment rollers, left and right each;

c) For each pair, there are two pieces of concentric rollers, top and bottom each, assembled with the same shaft;

d) In total, eight pieces of alignment and clamping rollers in one set of the machine;

2) Also can be seen from the above same picture, each pair of alignment rollers is guided with a guiding cover along leftward and rightward direction. Within each of these four guiding covers are leadscrew for transmission;

3) Assembly Drive Source of I H Beam Assembly Machine:

Now check picture of the machine as below. The oil cylinder at lower left of the picture (Inside red square frame) is for driving the above mentioned eight pieces of alignment and clamping rollers by way of leadscrew:

Hydraulic oil cylinder and pump station of Wuxi JACK H Beam Assembly Machine: (Fig.8)

a) Assembly Precision Guarantee: For the assembling steps in this automatic machine, the oil cylinder drives the four leadscrews inside the four guiding covers at the same time, making the leadscrews into transmission synchronously;

b) Workpiece Convey: With transmission of the leadscrews, the four guiding covers travel toward workpiece web in same pace (Two from left side of the web, and another two from right side) in the automatic machine;

c) Assembly Productivity: Thus in turn, the eight pieces of alignment and clamping rollers travel toward the web at the same pace (Four from left side of the web and another four from right side) in the machine:

Assembly process in Wuxi JACK I H Beam Assembly Machine: (Fig.9)

d) Firmly Workpiece Clamp: Upon the eight pieces of rollers touch the web at the same time, they hold and clamp the web firmly, fulfilling the task of self alignment of web with flange in the machine;

4) Process Steps: The above mention process happens two times for one piece of H Beam, for assembling into ⊥ shape beam first and then 工 shape beam following that.

4. Technical Parameters of Z20 Automatic H Beam Assembly Machine:

Model | Z20 Self Alignment with Manual Tack Welding H Beam Assembling and Tack Welding Machine |

Total Power | 18.7 kW + 2 x 12.8kW |

Hydraulic System Working Pressure | 6 ~ 8 MPa |

H Beam Web Width | 200 ~ 2,000 mm |

Range of H Beam Web Thickness | 6 ∽ 32 mm |

Range of H Beam Flange Width | 200 ∽ 800 mm |

Range of H Beam Flange Thickness | 6 ∽ 40 mm |

Range of H Beam Length | 4,000 ∽ 12,000 mm |

Max. H Beam Weight | 20 Ton. |

Web and Flange Alignment Style | Self Alignment, automatic assembly |

Tack Welding Style | Manual CO2 tack welding by operators |