Background: The Z18 model Self Alignment H Beam Assembly Machine in the attached first photo was being installed and commissioned at Wuxi JACK facility.

1. Outline on Usage and Working Steps of Z18 Self Alignment H Beam Assembling Machine with Manual Tack Welding:

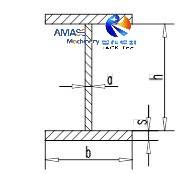

1) The finished workpiece from Z18 model H I Beam Assembly and Tack Welding Machine is assembled and tack welded H Beam with web height up to 1800mm:

Finished H Beam being produced: (Fig.1)

2) Subsequent Equipment Following I H Beam Assembling Machine:

The finished workpiece H Beam being delivered from the machine is not the final product that can be used for customer directly;

The assembled and tack welded H Beam needs to be:

a) Perform SAW welding in H Beam Submerged Arc Welding Machine;

b) Then to be straightened in the H Beam Straightening Machine following that;

3) Related Model: The three models of Z15, Z18, and Z20 I Beam Assembly Machine with Tack Welding have similar working steps as introduced previously in the product section of “Z15 model machine”.

2. Advantage and Disadvantage of Application of Manual Tack Welding H Beam Assembling Machine:

1) Advantage of Manual Tack Welding I Beam Assembly Machine:

a) For the advantages of manual CO2 tack welding compared with automatic, the first is its relative lower investment on equipment purchase of the machine:

Operating site of Wuxi JACK Z18 H Beam Assembly and Tack Welding Machine: (Fig.2)

b) The second is consequently less maintenance and service job for the machine: Less potential trouble points because of removal of PLC, A.C. Inverter, and subsequent assistant mechanical unit in the machine;

2) Meanwhile, manual CO2 tack welding in the H Beam Assembly Machine also has its disadvantages:

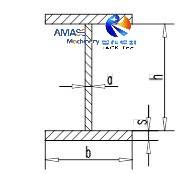

a) Requirement on Operators: Need two operators carry out welding at the same time (They should stand at both sides of the machine, and weld two pieces of seams on both sides of the workpiece together), instead of only one operator as in the case of automatic welding model machine:

Cross section view on Symmetric H Beam: (Fig.3)

b) Welding Quality: Compared with consistent welding seams generated in automatic CO2 tack welding of the H Beam Assembly Machine, manual CO2 tack welding usually delivers welded H Beam of obvious more variation, which poses great challenge on welding process quality control;

c) Operator Skill: In this respect, operators of the manual CO2 tack welding machine should command fairly proficient welding skill;

3) Application of Automatic versus Manual CO2 Tack Welding H Beam Assembly Machine in the market:

a) Domestic Customer Preference: Generally speaking, in China, up to now in purchase of the automatic model machine, manual CO2 Tack welding version is more often selected than automatic CO2 Tack welding version;

b) Overseas Customer Preference: While for exported Z series machine, automatic CO2 tack welding version sees more application.

3. Put into Work of Z Series H Beam Assembly Machine with Tack Welding:

1) Assistant Utility for H Beam Assembly Machine:

As can be observed from working process of the machine with tack weld, during its one round of complete operation cycle for one segment of welding seam, the workpiece of H Beam needs to be travelled thru the machine two times:

a) The first time assembled and welded into ⊥ shape beam, with the first and second pieces of seams welded:

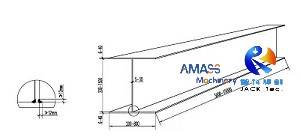

T Beam being produced: (Fig.4)

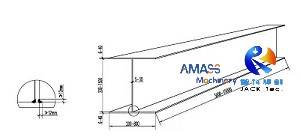

b) The second time assembled and welded into 工 shape beam, with the third and four pieces of seams welded:

Sketch on finished H Beam: (Fig.5)

c) Logistics Unit: During this process, travel crane is used for flipping and sending back the ⊥ shape workpiece back to input side of the I Beam Assembly and Tack Welding Machine. For this reason, the machine needs to be installed at the location with travel crane available overhead;

2) CO2 Tack Welding Power Supply in the H Beam Assembly Machine:

a) Proper Model: For CO2 tack welding power supply applied in the machine with tack welding, in automatic welding version we equip the model of 350A current welding power of either Chinese domestic or Japan brand:

CO2 welding power supply equipped with the machine: (Fig.6)

b) While in manual welding version, usually customer prepares the power supply. So, sometimes it is 350A, and sometimes 500A, both two types of options are feasible on the use of automatic H Beam Assembly Machine with tack welding.

4. Technical Parameters of Z18 H Beam Assembly Machine:

Model | Z18 Self Alignment with Manual Tack Welding H Beam Assembly and Tack Welding Machine |

H Beam Web Width (mm) | 200 ~ 1,800 |

Scope of H Beam Web Thickness (mm) | 6 ∽ 32 |

Scope of H Beam Flange Width (mm) | 200 ∽ 800 |

Scope of H Beam Flange Thickness (mm) | 6 ∽ 40 |

Scope of H Beam Length (mm) | 4,000 ∽ 12,000 |

Max. H Beam Weight | 20 Ton. |

Input and Output Conveyor Length | 3 x 2,600 mm each |

Input and Output Conveyor Motor Power | 1.1 kW x 2 |

Main Driving Motor Power | 5.5 kW |

Web and Flange Alignment Style | Self Alignment |

Tack Welding Style | Manual CO2 tack welding by operators |