1. Outline on ZHJ8018 Model 3 in 1 H Beam Welding Machine:

1) ZHJ8018 is the medium product in conventional models ZHJ series H Beam Assembly Weld Straighten Integral Machine, for making welding T Beam / H Beam of web height 200~ 1800mm;

2) Other specifications of delivered welding H Beam are similar to those of ZHJ8015 model 3 in 1 H Beam Fabrication Machine.

2. Comparison between PHJ and ZHJ series 3 in 1 H Beam Fabrication Machine:

1) Finished Workpieces from PHJ/ ZHJ Integral Function H Beam Welding Machine:

a) ZHJ Models: As introduced in the product page of Integral Function H Beam Welding Machine, ZHJ series automatic Vertical H Beam Welder focuses on producing symmetric cross section T Beam H Beam only;

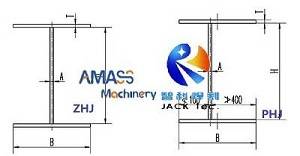

b) PHJ Models: While PHJ series Vertical H Beam Welder can produce both symmetric and asymmetric cross section welding H Beam. Shown as below figure:

Cross section view on finished welding H Beam being fabricated from 3 in 1 H Beam Welding Machine: (Fig.1)

2) Operating on PHJ and ZHJ Series SAW H Beam Fabrication Machine:

Difference between PHJ and ZHJ series Vertical H Beam Welder mainly happens at the assembling step:

a) In PHJ series automatic 3 in 1 H Beam Welding Machine, assembling T / H Beam is carried out in semi-automatic mode: One side of the H Beam is hydraulic drive, and the other side of the H Beam is with manual adjustment;

b) In ZHJ series H Beam Assembly Weld Straighten Integral Machine, the fitting up H Beam is fully automatically performed;

3) Structure and Working principle of PHJ Versus ZHJ Series 3 in 1 H Beam Welding Machine:

a) Difference also lies in assembly unit of the two branches of H Beam Fabrication Machine;

b) Welding unit and straightening unit are the same between PHJ and ZHJ branches Integral function H Beam Welding Machine;

c) To be specific, positioning of flange and web at both sides:

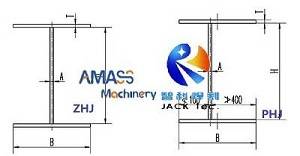

Working cell of PHJ series Integral Function H Beam Welding Machine: (Fig.1,2)

a) Drive: One side of H Beam web alignment rollers is driven with hydraulic cylinder, and the other side of H Beam web is adjusted manually by handwheel and leadscrew;

b) Transmission of alignment rollers: This is accomplished with hydraulic cylinder directly;

c) Guiding of alignment rollers: Movement of alignment rollers are guided along rectangular rail;

ZHJ series 3 in 1 H Beam Fabrication Machine: (Fig.3)

a) Drive: Both sides of H Beam web alignment rollers are driven with hydraulic cylinder in phase, connected together by a mechanical shaft which is installed at the bottom of the 3 in 1 H Beam Welding Machine mechanical main body;

b) Transmission of alignment rollers: Chain and sprocket;

c) Guiding of alignment rollers: Guiding bush, inside is nut and screw;

4) Manufacturing cost and quotation of PHJ / ZHJ Series 3 in 1 H Beam Welding Machine:

In general, manufacturing cost of ZHJ series Vertical H Beam Welder is about 5~6% lower than that of PHJ series;

5) Running cost and maintenance of PHJ / ZHJ Integral Function H Beam Welding Machine:

In general, PHJ and ZHJ series 3 in 1 H Beam Fabrication Machine are at the similar level, which major covers electricity and welding consumables;

6) Market Prospect of PHJ and ZHJ Integral Function H Beam Welding Machine:

a) Generally speaking, in China more customers prefer ZHJ series 3 in 1 H Beam Assembly Weld Straighten Integral Machine;

b) While in overseas market PHJ series 3 in 1 H Beam Fabrication Machine takes majority share.

3. Technical Parameters of ZHJ8018 model 3 in 1 H Beam Assembly Weld Straighten Integral Machine:

Below are technical specifications of standard ZHJ8018 model 3 in 1 H Beam Welding Machine:

Technical Parameter | ZHJ8018 H Beam Fabrication Machine |

Web Height | 200∼1800 mm |

Web Thickness | 6∼32 mm |

Flange Width | 150∼750 mm |

Flange Thickness | 6 ∼ 40 mm |

T Beam/ H Beam Length | 3000∼15000 mm |

Speed of Assembling/ Welding/ Straightening | 200∼1200 mm/min.(VFD) |

Single Pass Welding Seam Height | 8~ 12 mm |

Overall Size of Machine Main Frame L×W×H) | 28m × 4m × 5.1m |