The Significance of "Automation" on 3 in 1 H Beam Fabrication Machine:

1)“Automation” represents trend in today manufacture industry, especially in the field of involving heavy manual workload of steel structure;

2) “Automation” brings along benefits of efficient production of finished goods, with stable and controllable quality outcome.

1. Contribution on “Automation” with 3 in 1 I H Beam Assembly Weld Straighten Integrated Machine:

1) Meaning: In production of welding H Beam, the PHJ series and ZHJ series Automatic H Beam Fabrication Machine is the best product echoing this request;

2) "Automation” has the implication of “Relieve operator from routine works, and have machine do it”, to the ultimate goal of “Minimum operator”, in the process of manufacture. For this purpose, this Integral Function I H Beam Welding Machine helps removing on site manual work as much as possible:

3) Process Technology Simplification: Benefiting from operation of 3 in 1 H Beam Fabrication Machine, the original internal manual transferring H Beam WIP from Assembly to Welding, then to Straitening is eliminated;

4) Cycle Time Reduction: Reduces the original three times loading and unloading H Beam WIP to and from processing 3 in 1 H Beam Fabrication Machine to one time onto and off this automatic I H Beam Assembly Weld Straighten Integral Machine only;

5) Unified Working Speed: In 3 in 1 H Beam Fabrication Machine, combine the original different speed of H Beam Assembly/ Welding and Straightening into one consistent speed: H Beam Assembly Weld Straighten Integral Machine has the same speed for processes of H Beam assembling/ welding and straightening, which is VF (Variable Frequency) controlled and displayed in digital display meter, adapting to manufacturing of welding H Beam of various specification in the Pull Through I H Beam Welder;

6) Simplied Pull Through I H Beam Welder: Adjustment of parameters in this 3 in 1 H Beam Fabrication Machine on Assembling/ Welding and Straightening also becomes uniform one, from original individual manipulation of the 3 separate machines (H Beam Assembly Machine, and H Beam SAW Welding Machine, and H Beam Straightening Machine);

7) Meanging of "Automation": With the set up of critical operating parameters in PHJ series and ZHJ series integrated function Automatic H Beam Welding Machine (H Beam Fabrication Machine), including welding parameters of power supply/ wire feeder/ working speed of the Pull Through I H Beam Welder, the whole working process of this Automatic Integrated H Beam Welding Machine nearly does not need involvement of human intervention--- Operator just watch on and monitor its working process. This is where genuine sense of “Automation” lies in with this Automatic H Beam Fabrication Machine. Please check attached picture, for operator of this Automatic Integral function H Beam Welding Machine, most of the times they just need to stand alongside the Pull Through I H Beam Welder and watch on its working process;

8) Contribution: In this way, “Automation” is made into realization in the workshop of the Automatic H Beam Fabrication Machine, which sees more “sparse” operators and smoother material flow than conventional H Beam Production Line;

9) Production Efficiency Raise benefiting from 3 in 1 H Beam Fabrication Machine: Meanwhile, productivity is increased 30%~ 50% under the precondition of the best and persistent quality, rendering 40% ~ 60% operation cost (including period and variable) down.

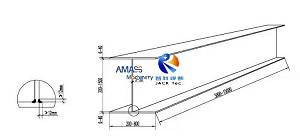

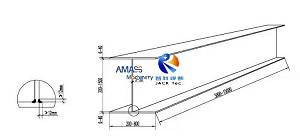

Workpiece illustration on 3 in 1 H Beam Fabrication Machine: (Fig.1)

2. Technical Parameters of Automatic H Beam Fabrication Machine:

Below are technical specifications of PHJ series and ZHJ Series H Beam Assembly Weld Straighten Integrated Machine:

Technical parameter | PHJ15 | PHJ18 | PHJ20 | ZHJ8015 | ZHJ8018 | ZHJ8020 |

| Automatic 3 in 1 H Beam Fabrication Machine |

Web Height | 200∼1500mm | 200∼1800mm | 200∼2000mm | 200∼1500mm | 200∼1800mm | 200∼2000mm |

Web Thickness | 5∼30mm | 6∼32 mm |

Flange Width | 200∼800mm | 150∼750mm |

Flange Thickness | 6∼40 mm |

Workpiece Length | 3000∼15000mm |

Single Pass Welding Seam Height | 8 ~ 12 mm |

Welding Speed (Assembly, Straighten same) | 200∼1200mm/min.(VFD) |

Machine size(L×W×H) | 28m×4m×4.6m | 28m×4m×4.9m | 28m×4m×5.1m | 28m×4m×4.2m | 28m×4m×4.5m | 28m×4m×4.8m |

Working Mode | Loading and Unloading: Manual; Assembly and Weld and Straighten: Automatic |