A. Outline on PHJ18 Welding H Beam Fabrication Machine:

1. Specialty and Usage: PHJ18 is the intermediate model between PHJ15 and PHJ20 in product group of PHJ series H Beam Assembly Weld Straighten Machine, for producing medium and medium large size welding T Beam H Beam (Some countries and regions call it I Beam);

2. Characteristics of PHJ Vertical H Beam Welder: For finished working parts (Welding H Beam) produced from PHJ series Integrated function H Beam Welding Machine, the two sides extended length of flanges from its joints with respect to web can be either equal or unequal;

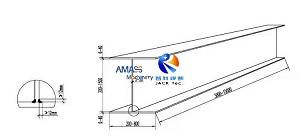

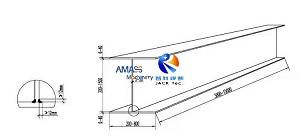

3. In other words, welding H Beam with both symmetric and non-symmetric cross section are available from PHJ series Vertical H Beam Welder. Please check below sketch:

4. 2 options on cross section of welding H Beam produced from PHJ Integral function H Beam Welding Machine: (Fig.1)

B. Working Units of PHJ Series SAW H Beam Welding Machine:

1. We give abbreviated description on Assembly/ Welding/ Straightening cells in PHJ series 3 in 1 H Beam Assembly Weld Straighten Machine in the product section of “PHJ15 Automatic H Beam Welding Machine”, please check it;

Below is introduction on remaining main mechanisms of this Vertical H Beam Welder:

2. Hydraulic Drive Manipulators in PHJ Series Integral function H Beam Welding Machine:

This part is for preliminary fit up of working parts in PHJ series 3 in 1 H Beam Welding Machine. It includes box structure table, hydraulic cylinder, claw and rollers. Shown as below:

Hydraulic aligning and fitting manipulators in PHJ and ZHJ Welding H Beam Fabrication Machine: (Fig.2)

Working manner of hydraulic manipulators in H Beam Assembly Weld Straighten Machine:

1) When the raw materials of flange and web (Cut from CNC Strip Plate Cutting Machine) is lifted onto input conveyor of PHJ series Integral function H Beam Welding Machine, the flange and web are probably not in the status of being correctly positioned, and need to be adjusted;

2) Besides, web needs be supported for keeping at its vertical upright position in the PHJ series Vertical H Beam Welder. This system of hydraulic drive manipulator can preliminarily hold the plates (Flange and web) under the drive of hydraulic cylinders;

Please check below photo taken on Wuxi JACK PHJ18 model 3 in 1 H Beam Welding Machine running at customer site: (Fig.3)

3. Input and Output Conveyor in PHJ Series 3 in 1 H Beam Welding Machine:

1) Function: These two sections are for the purpose of transporting raw materials (Flanges and web) into the main body of the H Beam Assembly Weld Straighten Machine, and sends out completed produced welding H Beam out of this Vertical H Beam Welder;

2) Driving Style: In every set of SAW H Beam Welding Machine, both input and output conveyors have one driving segment and two idler segments;

3) Elevating Available: The output conveyor has 2 segments of elevating stroke. This is considered for the situation of temporary up bending deformation of H Beam along its longitudinal direction after submerged arc welding in the Integrated function H Beam Welding Machine.

Shown as below photo:

Input conveyor of Wuxi JACK PHJ18 Automatic H Beam Welding Machine: (Fig.4)

4. Hydraulic System of PHJ18 Model 3 in 1 H Beam Welding Machine:

1) Role Play: This system supplies power for main operating steps of the PHJ series Integrated function H Beam Welding Machine. To be specific, the first step of assembling and the third step of straightening process;

2) Main Units: It is constituted from pump station, series of driving cylinder for different units of the Integral function H Beam Welding Machine: Manipulator, assembling, straightening, output conveyor elevation, tubes, electromagnetic valves, etc.;

Hydraulic pump station of Wuxi JACK PHJ18 model 3 in 1 H Beam Welding Machine: (Fig.5)

3) Control Manner: The hydraulic system has its control switches and buttons integrated into operating panel of the whole equipment of Welding H Beam Fabrication Machine;

5. Two sets of SAW Welding Power Supply in PHJ SAW H Beam Welding Machine:

1) Significance: This is the main outsourced parts of PHJ series SAW H Beam Assembly Weld Straighten Machine. It affects welding quality and productivity of workpiece in great extent;

2) There are numerous options on brands of SAW power supply to choose from for this Vertical H Beam Welder, from Chinese local brand to overseas;

3) The power supplies equipped in the PHJ18 3 in 1 H Beam Welding Machine in below photo are American brand Lincoln DC-1000: (Fig.6)

4) At customer site for arrangement of PHJ Welding H Beam Fabrication Machine, two sets of SAW power supplies are placed on workshop ground alongside hydraulic pump station;

5) Working Style: During operation of the PHJ Automatic H Beam Welding Machine, the 2 sets of SAW power supply perform flat fillet welding on both sides of flange, which is made at the same time in phase.

C. Technical Parameters of PHJ18 H Beam Assembly Weld Straighten Machine:

Below are technical specifications of this PHJ18 Integral function H Beam Welding Machine:

Technical Parameter | PHJ18 Welding H Beam Fabrication Machine |

Applicable H Beam Web Height | 200 ∼ 1800 mm |

Applicable H Beam Web Thickness | 5 ∼ 30 mm |

Applicable H Beam Flange Width | 200 ∼ 800 mm |

Applicable H Beam Flange Thickness | 6 ∼ 40 mm |

Applicable Workpiece (Welding H Beam) Length | 3000 ∼ 15000mm (At customer demand) |

Applicable Working Speed of Assembly/ Welding Straightening | 200∼1200 mm/min. (Stepless, Variable Frequency Drive) |

Height of Single Pass Welding Seam | 8~12 mm |

Workpiece (Welding H Beam) Cross Section | Symmetric and Asymmetric |

Overall Dimension of the Vertical H Beam Welder Mechanical Main Frame(L×W×H) | 28m × 4m × 4.9m |

Conveyor of 3 in 1 H Beam Welding Machine | Input and Output 10~11m length each, 3 segments each; One driving, two followers |

Applicable Driving Mode | Assembly/ Straightening: Hydraulic; Welding: Electric |

Applicable Welding Mode | SAW (Submerged Arc Welding, 2.5/3/4 mm diameter welding wire) |

Max. SAW Current | 1000 A |

Necessary Operator | 1 ~ 1.5 (Here 1.5 means a part time supporting staff) |