1. Equipment and Workpiece of HB2000 semi Automatic Welding H Beam Production Line:

1) The HB2000 semi automatic Welding H Beam Production Line adopts the largest standard model of welding H Beam Production Machine, producing welding H Beam with web height up to 2000mm;

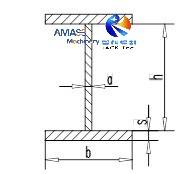

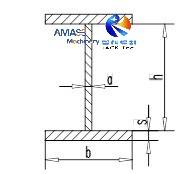

(Fig.1)

2) Based on the previous product section of “HB1800 semi Automatic Welding H Beam Production Line”, the alteration on equipment model of H Beam Production Machine in HB2000 Welding H Beam Production Line:

a) Z20 automatic H Beam Assembly machine with Tack Welding;

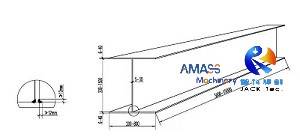

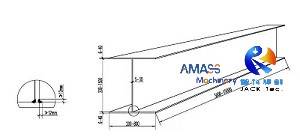

b) Submerged arc welding in H Beam Production Line:

i. LHA55Z Center control H Beam Gantry Welding Machine, or

ii. LHA5C Side control H Beam Gantry Welding Machine, or

iii. LHT T type H Beam Gantry Welding Machine

Either of three models has capability on producing H Beam of web height 2000mm. And, considering less operator, we recommend LHA55Z, or LHT model H Beam Gantry Welding Machine, which involves only one operator for operating the machine;

c) HYJ-40 H Beam Straightening Machine Flange straightening.

2. Content of Product Section of HB2000 semi Automatic H Beam Production Line:

As supplementary on the preceding section of HB1800 semi Automatic Welding H Beam Production Line, at this segment of HB2000, we will go on below topics of:

1) Environment Health Safety in running of HB series Welding H Beam Production Line;

2) Hoist of material among H Beam Production Machine in Welding H Beam Production Line;

3) Workshop Power Capacity of HB2000 Welding H Beam Production Line;

4) Installation on H Beam Production Machine of the Welding H Beam Production Line.

3. Environment Health Safety in running of HB series Welding H Beam Production Line:

1) Today EHS (Environment Health Safety) is important department in a facility of production industry. It is the basis and starting point of successful business running;

2) For running of heavy machinery of HB1500/HB1800/HB2000 Welding H Beam Production Machine, there exist potential risks of squeeze, bump, crash, eye harm, noise, etc. in daily working;

3) Proper PPE (Personal Protective Equipment) should be put on all the while in the process of operation of the Welding H Beam Production Line, including

a) Hard shoes in all the area of workshop;

b) Safety glasses in all the area of workshop;

c) Helmet when there is traveling crane overhead;

d) Facial Mask for Gas Shielded CO2 welding at H Beam Assembly Machine, which generates large sum of arc radiation in the process;

e) Ear Plug where there is heavy noise;

4) There is Safety Regulation in detail at beginning of each manual of our H Beam Production Machine, be sure to read it before putting into use on the Welding H Beam Production Line.

4. Hoist Materials among H Beam Production Machine in Welding H Beam Production Line:

1) Large lifting equipment and forklift are necessary for hoisting and transporting HB series H Beam Production Machine into place: H Beam Assembly Machine, H Beam Gantry Welding Machine, and H Beam Straightening Machine;

2) Qualified and certified personnel to take on the conveying job;

3) Abide by local lifting rules.

5. Workshop Power Capacity of the HB2000 Welding H Beam Production Line:

1) As introduced previously, the HB series Welding H Beam Production Machine have high electricity consumption:

a) Z20 H Beam Assembly machine with Tack Welding is around 45kW (18.7kW for machine, and 2x 12.8kW for CO2 welding Power Source;

b) LHA55Z or LHT H Beam Gantry Welding Machine is around 180kW (9kW for machine, and 2x 80kW for SAW power source, as well as 2x 5.5kW for Flux Recovery Unit);

c) HYJ-40 H Beam Straightening machine is around 25kW;

2) Summing up, the above three core H Beam Production Machine have total power of 250kW. So, workshop of HB2000 Welding H Beam Production Line should have 300~350KVA capacity;

3) Complement: For the counterpart of HB2000 in automatic line, please check product section of “Heavy duty HB2000 Automatic Welding H Beam Production Line”.

6. Technical Parameters of HB2000 Semi Automatic Welding H Beam Production Line:

Below are specifications of the Welding H Beam Production Machine in HB2000 Semi Automatic Welding H Beam Production Line:

Model | HB2000 Semi Automatic Welding H Beam Production Line |

Max. H Beam Web Width | 2000 mm |

Applicable H Beam Web Thickness Range | 6∽32 mm |

Applicable H Beam Flange Width Range | 200∽800 mm |

Applicable H Beam Flange Thickness Range | 6∽40 mm (Special thickness of 40~80mm also available) |

Applicable H Beam Length Range | 4000∽12000 mm |

Max. Weight of H Beam Delivered | 20 Ton. |

H Beam Production Machine for Assembly | Z20 H Beam Assembly Machine with Tack Welding |

H Beam Production Machine for Welding | LHA55Z, or LHA5C, or LHT H Beam Gantry Welding Machine |

H Beam Production Machine for Straightening | HYJ-40 mechanical H Beam Straightening Machine |

Transfer of H Beam workpiece among stations | Travel crane |