1. Application Site of HB2000 Heavy duty H Beam Production Line:

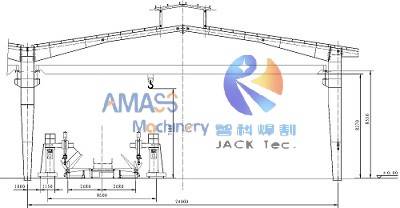

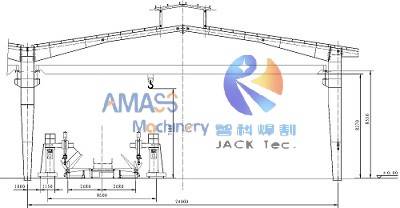

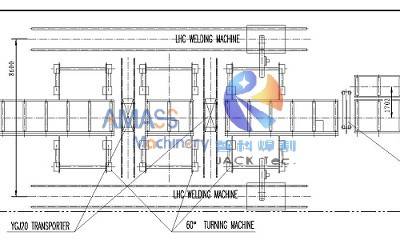

1) The attached first and second photos are aerial real shot, and design drawing of HB2000 Automatic Welding H Beam Production Line;

2) For deployment of all the H Beam Production Machine of this line, it needs around 100m length by 24m width workshop area for installation. The expected height for overhead travelling crane is 8.55m.

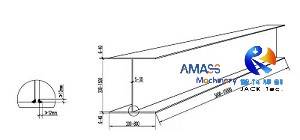

(Fig.1)

2. Special Point of HB2000 Automatic H Beam Production Line:

1) The HB2000 Automatic Welding H Beam Production Line is the largest of its kind in terms of both H Beam Production Machine specification, and the corresponding H Beam produced;

2) Conceivably, it is also the H Beam Production Line with the biggest investment. In Steel Structure industry, this line is directly called “Heavy Duty Line”, which is the abbreviation of automatic welding Heavy duty H Beam Production Line;

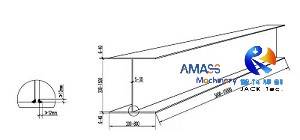

3) The biggest welding H Beam delivered from this Heavy Duty Line is 2000mm web height.

(Fig.2)

3. The detailed List on H Beam Production Machine applied in HB2000 Heavy duty Automatic H Beam Production Line:

In product section of “HB1500 High Efficiency Automatic Welding H Beam Production Line”, we give the three core H Beam Production Machine adopted in I Beam Production Line. Below is the detailed list on model and quantity of H Beam Production Machine in

a complete set of typical HB2000 Automatic H Beam Production Line:

1) CNC4000 Strip Plate Cutting machine of 4m Span 1 set

2) Z20 H Beam Assembly machine with automatic Spot Weld 1 set

3) 90° Hydraulic Overturning Rack 3 sets/group

4) LHC Column type SAW H Beam Welding Machine 4sets

5) YGJ15 Travel Cart 4 sets/2 groups

6) 60° Hydraulic Overturning Rack 12 sets/4 groups

7) YF1520 Movable 180°Hydraulic Overturning Rack 4 sets/2 groups

8) HYJ Mechanical or YTJ Hydraulic H Beam Straightening Machine 1set

9) Transportation Conveyor 1 set

4. The Application Feature of HB series Automatic Welding H Beam Production Line:

1) Of all the above listed equipment, the 1st set of CNC Strip Plate Cutting machine is a general purpose equipment not limited to being used in automatic I Beam Production Line. All the remaining products of the 2nd to 9th are all dedicated H Beam Production Machine;

2) From above can be seen, the arrangement of these H Beam Production Machine in the Automatic H Beam Production Line is in the form of modular type. Customer can determine specific model of H Beam Production Machine for each step based on their H Beam size;

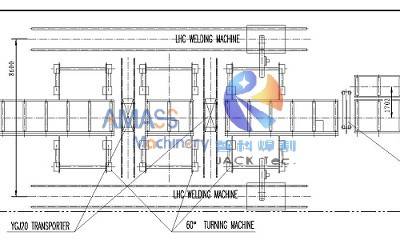

3) For example, the 1st step of H Beam Assembly Machine with tack welding can be Z15/ Z18/Z20, based on size of H Beam web. This is also true with the 3rd step of H Beam Straightening Machine: Either HYJ40 or HYJ800 mechanical (for max. 40mm flange thickness) or YTJ hydraulic (For flange thickness up to 40~80mm) can be chosen. (Fig.3)

5. Maintenance on H Beam Production Machine in Automatic I Beam Production Line:

1) HB series automatic or semi automatic H Beam Production Line usually takes on heavy workloads (2 shifts working system is not uncommon);

2) For the purpose of guaranteeing its long term stable running, thoughtful daily maintenance plan and strict enforcement is of vital importance for high level running of these H Beam Production Machine;

3) In manual of each set of H Beam Production Machine we give suggestion on machine service. Customer can draft their TPM plan combining practical condition; (Fig.4)

4) For example, hydraulic system of H Beam Assembly Machine:

a) Hydraulic oil grade:N32;

b) Observe oil level of oil tank regularly;

c) Please exchange oil regularly. For new H Beam Assembly Machine, after the first use of 6 months, it is necessary to replace new oil; From then on, replace oil every 6 months. Keep hydraulic oil clean. When applying oil, use 120 mesh sieve;

d) When exchange oil, be sure to first empty the oil tank and clean it, then apply new oil. (Fig.4)

6. Technical Parameters of HB2000 Automatic H Beam Production Line:

Below are specifications of the HB2000 Automatic Welding H Beam Production Line:

Model | HB2000 Heavy duty H Beam Production Line |

Max. H Beam Web Width (mm) | 2000 |

H Beam Web Thickness (mm) | 6∽32 |

H Beam Flange Width (mm) | 200∽800 |

H Beam Flange Thickness (mm) | 6∽40 (Special thickness of 40~80mm also available) |

H Beam Length (mm) | 4000∽12000 |

Max. H Beam Weight | 20 Ton. |

H Beam Production Machine for Assembly | Z20 H Beam Assembly Machine with Tack Welding |

H Beam Production Machine for Welding | LHC Column structure H Beam Welding Machine |

H Beam Production Machine for Straightening | HYJ800 or YTJ H Beam Straightening Machine |

Transfer of H Beam workpiece among stations | With Flipping units/ Conveyor/ Travel Cart |