A. Function of Welding Preparation SXBJ-9 Automatic Sheet Metal Edge Milling Machine:

1. As its product name suggests, SXBJ-9 Automatic Sheet Metal End Beveling Machine is a 1st operation equipment for doing sheet metal plate welding preparation;

2. To be specifically, edges of workpieces sheet metal plate can be beveled in the SXBJ-9 Automatic Sheet Metal Plate Beveling Machine in high efficiency and top grade quality, so that welding groove can be made on these metal plates;

3. This is especially useful for fabricating those sheet metal with thickness thicker than 15mm, which can get the ideal penetration and fusion on welding seam fabricated subsequent to Edge Milling Machine;

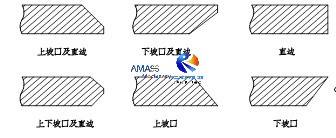

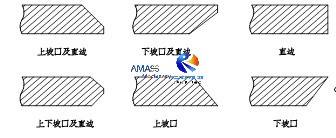

4. Types of Welding Grooves Produced from SXBJ-9 Automatic Sheet Metal End Beveling Machine:

1) In XBJ and SXBJ series Automatic Sheet Metal Edge Beveling Machine, equipped with proper facer blade, the X/ Y/ U/ V types of bevels can be machined in high speed, by means of 7.5kW/ 9kW/ 11kW milling heads produced from top grade professional suppliers in the industry;

2) List of sketches on common seen X/ Y/ V chamfers produced from Automatic Sheet Metal Edge Milling Equipment: (Fig.1)

3) Here, the milling cutter equipped in XBJ and SXBJ series Edge Milling Machine is internationally universal: By means of fitting on proper mandrel, it can be assembled onto milling head spindle. The model of spindle is ISO50, taper 7:24, which is universal in market and industries internationally;

4) The international universal milling cutter equipped in SXBJ-9 Automatic Sheet Metal Edge Beveling Machine: (Fig.2)

5) The typical X groove produced from Wuxi JACK SXBJ-9 Automatic Sheet Metal Edge Milling Machine: (Fig.3)

6) Installed with special made round milling cutter, the XBJ series Plate Beveling Machine can also produce round arc welding groove: (Fig.4)

B. Main Components in SXBJ-9 Automatic Sheet Metal End Beveling Machine:

Main components of the XBJ and SXBJ series General Purpose Edge Milling Machine can be classified into 2 general groups of outsourcing parts and Wuxi JACK self made parts:

1. Main Outsourcing Parts in SXBJ-9 Edge Milling Machine:

1) Milling Head of the SXBJ-9 Edge Beveling Machine:

a) For XBJ and SXBJ series Edge Milling Machine, the default setting of milling head is 7.5kW;

b) Under special conditions, when workpiece has thickness thicker than 80mm, up to 160mm; Or customer has special requirement on single stroke cutting depth of Edge Milling Machine, the power of milling head can be 9kW or even 11kW;

c) In Wuxi JACK Edge Beveling Machine, spindle of milling head has 6 shifts of revolutionary speed to switch among, which is modulated by means of turning speed lever on cover of milling head. Shown as below:

d) The 7.5kW milling head equipped in Wuxi JACK Edge Milling Machine, and its speed regulation lever: (Fig.5)

e) Such milling head is also the central working element in DX series Beam End Face Milling Machine;

2) Hydraulic Pump Station of the XBJ and SXBJ Series End Beveling Machine:

a) Hydraulic pump station is for providing energy on array of jacks, which are installed beneath pressing beam of the Edge Milling Machine, to press workpieces tightly during edge milling operation;

b) In Wuxi JACK Edge Milling Machine, hydraulic pump station is independently deployed alongside main frame of the Edge Milling Equipment. This guarantees stable performance and convenient service on the Edge Milling Machine;

c) Comparatively, some competitors install their pump station inside mechanical main frame of the Plate Beveling Machine. This will reduce manufacturing cost of the End Beveling Machine, but brings along inferior bad heat dissipation of entire hydraulic pump station;

d) The independently arranged hydraulic pump station for Wuxi JACK Edge Milling Machine: (Fig.6)

3) Facer blade installed on milling head. This has been introduced in the previous segment;

4) A.C. Inverter in Electric Control System of XBJ and SXBJ Series End Beveling Machine:

a) Inverter is for realizing continuous working speed control of the Edge Milling Machine, within the range of 130~ 1000 mm/min.;

b) A potentiometer is connected onto input port of the inverter, which is adjusted by means of a speed knob installed on operating pendent of the Plate Beveling Machine;

5) Top Level Precise linear Guiderail in SXBJ-9 Edge Milling Machine:

a) Here, “Top Level” is a punch line which has two implications: First, this linear guiderail is installed at top position of Edge Milling Equipment mechanical bed;

b) Second, the precise linear guiderail assembled onto Wuxi JACK XBJ and SXBJ series single and double heads Edge Milling Machine is HIWIN brand, which is top grade in the industry and market;

c) The top level precise linear guiderail for guiding of milling head movement in Wuxi JACK End Beveling Machine: (Fig.7)

2. Wuxi JACK Self Made Parts in SXBJ-9 Edge Beveling Machine:

1) Mechanical base bed of the SXBJ-9 Edge Milling Machine, which has total length of: 9m edge milling stroke + 6m for accommodating the 2 pieces of milling head carriages, equals to 15m;

2) Bottom level guiderail for guiding movement of Plate Beveling Machine milling head carriages: This guiderail is produced from #45 steel, precisely machined and strictly heat treated;

3) Double stage protecting cover on milling heads, to prevent milling scraps from falling onto milling head and its facer blade, during running of the SXBJ-9 Edge Milling Machine.

C. Technical Parameters of SXBJ-9 Automatic Sheet Metal Edge Milling Machine:

Below are technical specifications of the SXBJ-9 Double Heads Automatic Sheet Metal End Beveling Machine:

Model Technical parameter | SXBJ-9 Double Heads Automatic Sheet Metal Edge Beveling Machine |

Max. Plate Beveling Length | 9000 mm |

Length of Mechanical Main Frame | 15m |

Milling Angle of the Plate Beveling Machine | 0°~80° for up edge milling; -45°~0° for lower edge milling; |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Head Quantity | 2 sets |

Plate Thickness for Sheet Metal Chamfering | 6∼80 mm |

Edge Milling Speed | 130∼1000 mm/min. (VFD, Inverter Control) |

Idle High Speed of Milling Head | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200 For delivery) |

Quantity of Hydraulic Drive Jacks for Pressing Workpieces | 15 pieces |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 450 mm |

Worktable Height | 1050 mm |