We give the ZHJ series Welding H Beam Fabrication Machine the descriptive of “Efficient”, because it really has high productivity in producing consistent good quality welding H Beams and T Beams.

A. Operation of ZHJ Series SAW I H Beam Welding Machine:

1. Finished Workpiece from ZHJ Models 3 in 1 I H Beam Assembly Welding Straightening Integral Machine:

1) The attached heading picture (The first photo) was taken at a customer site. We can see there are 2 sets of ZHJ8015 automatic H Beam Welding Machine (SAW H T Beam Welding Machine) in a line;

2) These 2 sets of H Beam Assembly Welding Straightening Integral Machine are the major manufacturing equipment in this workshop;

3) The finished workpieces delivered from this high efficiency Vertical I H Beam Welder are piled on the ground: The welding H Beams of symmetric section shape;

2. View on 3 in 1 H T Beam Welding Machine at Workshop:

1) The ZHJ8015 H Beam Fabrication Machine in the photo is taken from its frontage: Workpiece coming out side;

2) The visible conveyor in the photo is output section of the Vertical I H Beam Welder;

3) So, there is no hydraulic manipulators on the output conveyor of H Beam Fabrication Machine: Hydraulic drive manipulators are installed at input conveyor of 3 in 1 I H Beam Welding Machine;

3. Working Pace in ZHJ Series I H Beam Fabrication Machine

This is very quick and regular:

1) Material Prepare: With the loading on of raw materials (Long strip steel plate cut from CNC Strip Plate Cutting Machine) used as flange and web, all the following steps of operation:

2) Core Steps: From first stage centering on flange and web, to the next phase of fine assembling on flange and web, to SAW (submerged arc welding) or CO2 welding on flange and web, to the final step of straightening on H Beam flange after welding, including the adjustment of welding torch position and straightening rollers, can all be completed with the corresponding buttons and toggle switches on operating panel of this SAW I H Beam Welding Machine (3 in 1 H T Beam Welding Machine);

c) Especially for the original complicated task of H Beam flange and web fitting up, just start on the corresponding switch “EDGE CLAMP”/ “EDGE RELEASE”, hydraulic cylinders will act to implement the corresponding process in the Vertical I H Beam Welder;

d) Operating panel of the ZHJ series H Beam Assembly Welding Straightening Integral Machine please see attached the 2nd photo.

B. Working Units of ZHJ Series Automatic 3 in 1 H T Beam Welding Machine:

1. Welding Modes Available in ZHJ Series 3 in 1 T H Beam Welding Machine:

1) ZHJ series H Beam Fabrication Machine can adopt welding mode of either SAW, working as SAW H Beam Welding Machine (SAW T Beam Welding Machine), or CO2 GMAW;

2) The attached 3rd and 4th photos take working moment of two welding modes for producing welding T Beam respectively in this T I H Beam Welding Machine (H Beam Fabrication Machine, or 3 in 1 H Beam Assembly Welding Straightening Integral Machine);

3) The 5th photo provides close up view on welding torch. As can be seen from it, welding torch in this T I H Beam Welding Machine (Vertical I H Beam Welder) has 2 stages of positioning:

2. ZHJ series SAW H Beam Welding Machine Two stages of Welding Torch Position Control

1) First phase is by mean of its 45° oblique angle sliding mechanism in the Vertical I H Beam Welder, which is moved under D.C. motor drive. This is for leaving out sufficient space during workpiece coming in and out (To avoid bumping with workpiece) of the integral function H Beam Welding Machine;

2) The second phase is by means of a mechanical cross slides installed at back side of the 45°mechanism (Please check the attached picture) in the Vertical I H Beam Welder. It is manual turning on handwheel and then make the leadscrew into driving. This high precision cross slides can have fine tuning of welding torch position in X and Y axis, before welding operation in the SAW H Beam Fabrication Machine (H T Beam Welding Machine);

3) As can be confirmed from attached photo, both mechanisms have linear guiderails for precise guiding of the welding torches.

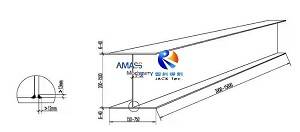

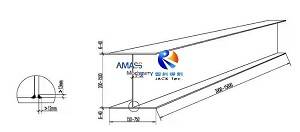

Welding H Beam produced from 3 in 1 H Beam Fabrication Machine: (Fig.1)

3. Technical Parameters of ZHJ8015 SAW H Beam Welding Machine:

Below are technical specifications of this ZHJ8015 Welding T H Beam Welding Machine:

Technical Parameter | ZHJ8015 Efficient SAW H Beam Welding Machine (H Beam Assembly Welding Straightening Integral Machine) |

Finished H Beam Web Height | 200 ∼ 1,500 mm |

Finished H Beam Web Thickness | 6 ∼ 32 mm |

Finished H Beam Flange Width | 150 ∼ 750 mm (200 ~ 800mm available for special made) |

Finished H Beam Flange Thickness | 6 ∼ 40 mm |

Workpiece (Welding H Beam) Length | 3,000mm ∼ 15,000 mm (Based on customer demand) |

Unified Working Speed of Assembly/ Welding Straightening | 200∼1200 mm/min. for both SAW and CO2 (Stepless, A.C. inverter Control, adjusted with potentiometer) |

Height of Single Pass Welding Seam | Max. 8~12 mm, flat fillet welding of SAW/ CO2 |

Workpiece (Welding H Beam) Cross Section | Symmetric Only (Refers to H Beam Section shape) |

Overall Dimension of the Vertical I H Beam Welder Main Body (L×W×H) | 28m × 4m × 4.2m |

Input and Output Conveyors | Input / Output 10~11m length each,3 segments each; One segment driving, two segments Idling type Input conveyor has three pairs of manipulators |

Driving Mode | Assembly/ Straightening: Hydraulic Cylinder; |

Welding Mode | Most majority: SAW (Submerged Arc Welding, 2.5/3/4 mm diameter welding wire), Single Arc or Twin Arc Minority: CO2 Gas shielded Welding |

Max. Welding Current | Up to 1000 A for SAW; 420A for CO2 |