Working Phenomenon of Wuxi JACK 3 in 1 H Beam Fabrication Machine:

The attached master (the first one) picture records on working moments of Wuxi JACK PHJ15 model 3 in 1 H Beam Fabrication Machine working at customer site.

A. Task of PHJ15 H Beam Assembly Weld Straighten Machine and its Fulfilment:

1. From T Beam to H Beam in PHJ15 Integral Function H Beam Welding Machine:

The master picture shows beginning of the second round operation for fabricating one piece of welding H Beam in this Vertical H Beam Welder (H Beam Welding Machine):

1) At the completion of T Beam welding, the second piece of flange is hoisted onto the WIP workpiece along input conveyor of the integral function H Beam Welding Machine;

2) In this way, the fabricated T Beam will be made into the final structure of H Beam;

3) Next, the WIP (Work in process) workpiece will be repeated the steps as completed in its first round of T Beam welding in the 3 in 1 H T Beam Welding Machine:

a) The flanges and web are clamped and positioned by means of hydraulic drive alignment units;

b) In the same route being pulled through in the Vertical H Beam Welder, the working part is welded with SAW (Submerged arc welding) system;

c) And at the same time, being straightened right following the SAW welding;

With these the above mentioned one flow steps, one piece of welding H Beam is finished fabircation in PHJ15 Integral function H Beam Fabrication Machine;

2. One Equipment as Both 3 in 1 T Beam Welding Machine and 3 in 1 H Beam Welding Machine:

1) Consequently, from the above steps we can draw conclusion, that PHJ15 Vertical H Beam Welder (The name is arisen out of the fact that H Beam is welded in vertical position in this H Beam Welding Machine) can also be applied as T Beam Welding Machine;

2) This is shown the attached second picture: A set of green color T Beam Welding Machine is delivering a piece of welding T Beam;

3) The two equipment in the first and second attached photos have same structure and working principle and can be exchanged, for making either welding H Beam or welding T Beam:

Welding T Beam completed fabrication from Wuxi JACK 3 in 1 T Beam Welding Machine: (Fig.1)

From T Beam to H Beam in the same set of Wuxi JACK 3 in 1 H Beam Welding Machine: (Fig.2 )

B. Mecanical Base Bed of PHJ15 Integrated Automatic H Beam Welding Machine:

1. Importance and Structure of Mechanical Main Frame of 3 in 1 H Beam Assembly Weld Straighten Machine:

1) Significance: Base bed is the foundation of PHJ series Integral Automatic H Beam Welding Nachine (3 in 1 T Beam Welding Machine);

2) Formation: Assembled with U shape gantry, the mechanical bed is composed into main body of the 3 in 1 H Beam Fabrication Machine;

3) Please check attached 3rd and 4th pictures and below photos, on base bed and assembled main body of the PHJ series H Beam Assembly Weld Straighten Machine respectively:

Batch production on mechanical base bed of 3 in 1 H Beam Assembly Weld Straighten Machine at Wuxi JACK: (Fig.3)

Assembled into main body of Wuxi JACK 3 in 1 H Beam Assembly Weld Straighten Machine: (Fig.4)

2. Main Units in Mechanical Main Frame of 3 in 1 H Beam Fabrication Machine:

1) Base bed has two main sections of pedestal and two pieces of top assembled C shape brackets, which form up lateral side of H Beam Fabrication Machine main body;

2) Mechanical C Frame in Integral Function T H Beam Welding Machine:

The C shape brackets have two functions:

a) One is to construct a relative enclosed working area of the 3 in 1 H Beam Welding Machine (T Beam Welding Machine);

b) The other function is to have a lateral opening for the purpose of easy operation in the Vertical H Beam Welder: When adjust flange alignment with manual handwheels, operator can get access to this operating zone without hinderance;

Mechanical base C frame of Wuxi JACK 3 in 1 T H Beam Welding Machine: (Fig.5)

3) Comparatively, ZHJ series Integrated Automatic H Beam Welding Machine has enclosed lateral side, because both sides of flange alignment are all made with hydraulic cylinders, without human intervention;

3. Pedestal of the Vertical H Beam Welder is strong and sturdy box structure, which will be assembled firmly into workshop floor during installation of the PHJ series 3 in 1 H Beam Fabrication Machine;

4. The C structure bracket has grid shape cross section. Which, not only gives the Integrated Automatic H Beam Welding Machine (T Beam Welding Machine) good appearance, but also increases its strength and stability in great extent:

Grid structure in C frame of the Wuxi JACK Integral Function 3 in 1 T H Beam Welding Machine: (Fig.6)

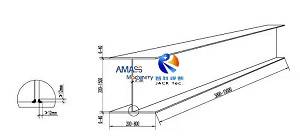

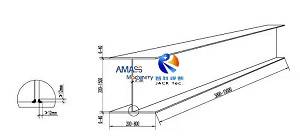

Welding H Beam to be produced from Wuxi JACK Integral Function 3 in 1 T H Beam Welding Machine (Fig.7)

C. Technical Parameters of PHJ15 Integrated Automatic H Beam Welding Machine:

Below are technical specifications of this PHJ15 Integrated Automatic H Beam Welding machine (T Beam Welding Machine):

Technical Parameter | PHJ15 Model 3 in 1 H Beam Fabrication Machine |

Web Height | 200 ∼ 1500 mm |

Web Thickness | 5 ∼ 30 mm |

Flange Width | 200 ∼ 800 mm |

Flange Thickness | 6 ∼ 40 mm |

Workpiece (Welding H Beam) Length | 3,000 ∼ 15,000 mm (At customer demand) |

Working Speed of Assembly/ Welding Straightening | 200 ∼1,200 mm/min. (Stepless, Variable Frequency Drive) |

Height of Single Pass Welding Seam | 8~12 mm |

Workpiece (Welding H Beam) Cross Section | Symmetric and Asymmetric (Welding H Beam Cross Section) |

Overall Dimension(L×W×H)of Integral Function 3 in 1 T H Beam Welding Machine | 28m × 4m × 4.6m |

Conveyor | Input and Output 10~11m length each, 3 segments each; One driving, two idlers |

Driving Mode | Assembly/ Straightening: Hydraulic oil cylinder; Welding: Electric motor |

Welding Mode | Single Arc SAW (Submerged Arc Welding, 2.5/3/4 mm diameter welding wire) at fillet flat position |

Operator | 1 ~ 1.5 (1.5 means a part time support) |