Background of Introducing on 3 in 1 H Beam Fabrication Machine:

1) Critical Factor: Nowadays floor space occupation of equipment is a very important factor to consider by customers, when making plan for workshop and purchasing machine;

2) The reason behind that is, at one side facility utility takes great share in investment, and at other side highly efficient material flow calls for tight layout of machines;

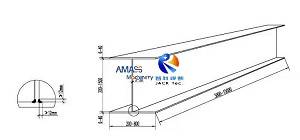

3) Workpiece sketch applicable for Wuxi JACK H Beam Assembly Welding Straightening Integral Machine: (Fig.1)

A. Contributions on Land Saving by PHJ Series and ZHJ Series H Beam Fabrication Machine:

1. The PHJ and ZHJ series 3 in 1 H Beam Assembly Welding Straightening Integral Machine responds to this trend:

One set of the 3 in 1 H Beam Welding Machine has the overall dimension close to either one set of:

1) H Beam Assembly and Tack Welding Machine;

2) H Beam SAW Welding Machine;

3) H Beam Straightening Machine,

but with the function integrated with the above listed three sets of the H Beam Production Machine, the original land occupation by the above three sets of H Beam Production Machine is reduced 60~70%. In other words, with installation of PHJ and ZHJ models 3 in 1 H Beam Welding Machine, the workshop floor for welding H Beam production is reduced to 30% of the original area;

2) Below is the detailed list of size of PHJ and ZHJ series 3 in 1 H Beam Welding Machine versus traditional H Beam Assembly Machine, H Beam SAW Welding Machine and H Beam Straightening Machine:

Standard Machine of: | Length (m) | Width (m) | Height (m) |

PHJ and ZHJ series 3 in 1 H Beam Assembly Welding Straightening Integral Machine | 25~ 28 | 4 | 3.8~ 5.1 |

H Beam Assembly Machine | 25~ 28 | 3.5 | 3.6 |

H Beam Welding Machine | 18~ 20 | 4.5 | 3.5 |

H Beam Straightening Machine | 23~ 25 | 3 | 2.4 |

B. In Depth Analysis on Land Saving by PHJ Series and ZHJ Series H Beam Assembly Welding Straightening Integral Machine:

From the above parameters table we can see,

1. Land Occupation of Workshop of Traditional H Beam Production Machine Versus 3 in 1 H Beam Welding Machine:

1) With the traditional 3 sets of H Beam Production Machine: Assembly/ Welding/ Straightening, the total land occupation is around 297~ 329m2;

2) While with this PHJ and ZHJ models Fit Up Full H Beam Welding Machine (H Beam Fabrication Machine), the land occupation is only around 100~112m2;

2. Manufacturing Efficiency Study on 3 in 1 H Beam Assembly Welding Straightening Integral Machine:

The above comparison is made on the basis of:

1) One Machine equals to Three Machines: One set of PHJ and ZHJ series Integral Automatic H Beam Welding Machine (H Beam Assembly Welding Straightening Integral Machine) has higher productivity compared with that of the traditional three H Beam Production Machine combined, which is around 20%~30% efficiency raise;

2) Which means, not only 20%~30% higher productivity, but also 60%~70% less land occupation;

3) We can see that, this Pull Through H Beam Welder (Automatic H Beam Production Machine) is truly a best solution for customers producing light duty and medium duty welding H Beam, in terms of best quality, higher production efficiency and lower cost;

3. The three sets of traditional H Beam Production Machine: Assembly/ SAW Welding/ Flange Straightening, its overall size is at around the same level with each other, also at the same level with this Automatic H Beam Welding Welding (H Beam Fabrication Machine);

4. So, PHJ series and ZHJ series 3 in 1 Beam H Welding Machine reduces floor space to original one third level of H Beam Production line;

5. Besides, considering transferring unit, the use of this compact Fit Up Full Beam Welding Machine (H Beam Fabrication Machine) only takes one fourth of original floor space of the 3 sets of H Beam Production Machine combined. This fully demonstrates PHJ series and ZHJ series H Beam Assembly Welding Straightening Integral Machine reputation as “compact”;

6. Quality Assurance with PHJ and ZHJ series Fit Up Full H Beam Welding Machine:

With the combining of the original three sets of H Beam Production Machine to single set of equipment 3 in 1 H Beam Welding Machine, many assistant stations and assessment index are also removed:

1) IPV (Internal Process Validation);

2) QG (Quality Gate);

3) WIP (Working in Process)... Removing quality risk of 3 in 1 H Beam Welding Machine to the minimum level;

7. The material flow becomes more fluent and effective, with the original H Beam production line turns into an individual set of 3 in 1 H Beam Fabrication Machine.

3. Technical Parameters of H Beam Fabrication Machine:

Below are technical specifications of PHJ series and PHJ series Integral Automatic H Beam Welding Machine:

Technical parameter | PHJ15/ 18/ 20 Model 3 in 1 H Beam Fabrication Machine | ZHJ8015/ 8018/ 8020 Model 3 in 1 H Beam Fabrication Machine |

Web Height | 200∼1500/ 1800/ 2000 mm | 200∼1500/ 1800/ 2000 mm |

Web Thickness | 5∼30 mm | 6∼32 mm |

Flange Width | 200∼800 mm | 150∼750 mm |

Flange Thickness | 6∼40 mm |

Workpiece Length | 3000∼15000 mm |

Single Pass Welding Seam Height | 8 ~ 12 mm |

Welding, Assembly, Straighten Speed | 200∼1200 mm/min. (A.C. Inverter Control) |

Machine Size (L×W×H) | 28m×4m×4.6m | 28m×4m×4.9m | 28m×4m×5.1m | 28m×4m×4.2m | 28m×4m×4.5m | 28m×4m×4.8m |