Huge Benefits of 3 in 1 H Beam Assembly Welding Straightening Machine:

1) Integrated Functions: As the name of PHJ and ZHJ series 3 in 1 H Beam Assembly Welding Straightening Machine implies, the essence of such 3 in 1 SAW H Beam Fabrication Machine is its integration of the three critical steps:

2) And hence traditionally three individual machines of welding H Beam Production Line being integrated into single set of 3 in 1 H Beam Welding Machine:

3) H Beam Assembly Machine, plus H SAW Beam Welding Machine, plus H Beam Straightening Machine;

4) This brings along all the benefits of PHJ and ZHJ series 3 in 1 H Beam Fabrication Machine:

Including:

a) Great margin of less equipment investment -- 60% budget reduction;

b) Less workshop area occupied --- 60% floor space less;

c) Less operator needed --- From 6 operators in H Beam Production Line, to only 1 operator in 3 in 1 H Beam Fabrication Machine;

d) And hence less machine maintenance working load, as well as daily variable running cost.

1. Structure Characteristics of PHJ and ZHJ Models 3 in 1 H Beam Welding Machine:

1) Before Introduction of SAW H Beam Fabrication Machine:

Typical H Beam Production Line incorporates 3 core equipment of:

a) The conventional H Beam Assembly and Tack Welding Machine;

b) H Beam SAW Welding Machine;

c) H Beam Straightening Machine

Share the similar structure of mechanical main body with input conveyor at its front side, and output conveyor at its rear side. The machine body incorporates sole function of Assembling/ SAW welding/ Flange straightening respectively;

2) Constructure of 3 in 1 H Beam Assembly Welding Straightening Machine:

a) Comparatively, at first glance, the structure of PHJ and ZHJ series 3 in 1 H Beam Fabrication Machine (3 in 1 H Beam Welding Machine) resembles that of H Beam Assembly and Tack Welding Machine:

b) A fixed gantry style main body equipped with input and output conveyors of this 3 in 1 H Beam Welding Equipment, with the function units installed at the gantry and base machine body;

c) Different from H Beam Assembly Machine, besides Assembly unit, to attain target of welding H Beam production with single machine of SAW H Beam Fabrication Machine, structure of this 3 in 1 H Beam Assembly Welding Straightening Machine integrates the corresponding three function units of assembly/ welding and straightening into one gantry and base machine body, making it a compact Pull Through H Beam Welder;

3) The original two steps of welding in the PHJ and ZHJ Series3 in 1 H Beam Assembly Welding Straightening Machine:

a) First step: CO2 tack welding;

b) Second step: SAW welding ;

Are performed at H Beam Assembly Machine and H Beam SAW Machine respectively, are now combined into one step of either SAW (Submerged Arc welding, most majority) or CO2 welding (Minority, for light duty welding H Beam only) in this 3 in 1 Welding H Beam Fabrication Machine (H Beam Assembly Welding Straightening Machine);

4) Deployment of 3 Function Cells: In the direction of workpiece going forward, sequence of function units deployed at main body of this combined and compact H Beam Welding Equipment (3 in 1 H Beam Welding Machine) are Assembly unit/ Welding unit and Straightening unit;

Below is its brief summary on PHJ and ZHJ series H Beam Assembly Welding Straightening Machine:

a) Assembly Unit of 3 in 1 SAW H Beam Fabrication Machine:

i. Includes 3 sets of hydraulic drive manipulators (Pulling rod system, hydraulic driven) among input conveyors of the 3 in 1 H Beam Assembly Welding Straightening Machine, for fulfilling rough aligning and positioning of flange and web;

ii. And 2 sets of accurate positioning units (Alignment rollers, also hydraulic driven) for clamping on flange and web each;

b) Welding unit of 3 in 1 H Beam Welding Machine: SAW (Submerged arc welding) or CO2;

c) Straightening Unit of 3 in 1 H Beam Fabrication Machine:

i. Why flange straightening in 3 in 1 H Beam Assembly Welding Straightening Machine: Deformation happens at the flanges post SAW welding, because of SAW heat input;

ii. To eliminate it, at exit side of the SAW H Beam Fabrication Machine following welding unit is straightening unit;

iii. This is a powerful downstroke straightening roller of hydraulic drive, with heavy force and convenient control.

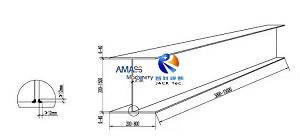

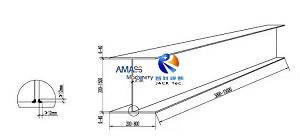

Welding H Beam to be fabricated from 3 in 1 H Beam Assembly Welding Straightening Machine: (Fig.1)

2. Technical Parameters of 3 in 1 H Beam Assembly Welding Straightening Machine:

Below are major technical specifications of PHJ and ZHJ series 3 in 1 H Beam Assembly Welding Straightening Machine:

Technical Parameter | PHJ15~PHJ18~ PHJ20 3 in 1 H Beam Fabrication Machine

| ZHJ8015 ~ZHJ8018~ ZHJ8020 3 in 1 H Beam Fabrication Machine |

Web Height | 200∼1500/1800/2000 mm | 200∼1500/ 1800/ 2000 mm |

Web Thickness | 5∼30 mm | 6∼32 mm |

Flange Width | 200∼800 mm | 150∼750 mm |

Flange Thickness | 6∼40 mm |

Workpiece Length | 3000∼15000 mm |

Single Pass Welding Seam Height | 8 ~ 12 mm |

Welding Speed (Assembly, Straighten same) | 200∼1200 mm/min. (A.C. Inverter Control) |

Machine Main Frame Size(L×W×H) | 28m × 4m ×(4.6/ 4.9/ 5.1) m | 28m × 4m × (4.2/ 4.5/ 4.8) m |