1. Application Field of HJ-100 Longitudinal H Beam Straightening Machine:

1) Applicable Workpiece Sizes: HJ-100 is medium and light duty Longitudinal Straightening Machine, for straightening on H Beam with the max. size of web width 500mm and thickness 12mm, and flange height 400mm and thickness 20mm:

Lengthways deflected H Beam need to be straightened in Longitudinal Straightening Machine: (Fig.1)

2) For other kinds of workpiece (Section steel, Structure members, BOX beam, etc.) please take the above data as reference.

2. HJ-100 Longitudinal H Beam Straightening Machine:

1) For HJ series Longitudinal I Beam Straightening Machine:

a) Straightening Principle in the product section of “HJ series”;

b) Empirical data in the product section of “HJ-300 Hydraulic Heavy Duty”;

c) Operation process in the product section of “HJ-200 Hydraulic High Efficiency ”;

2) In this section of HJ-100 we will have an introduction on structure and main components of the HJ series Structural Member Longitudinal Straightening Machine.

3. Structure and Main Components of the HJ series H Beam Longitudinal Straightening Machine:

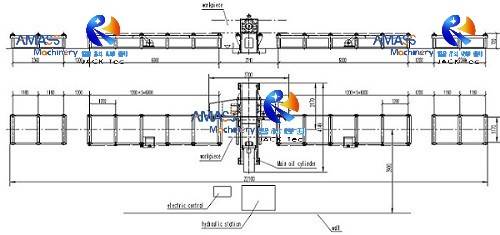

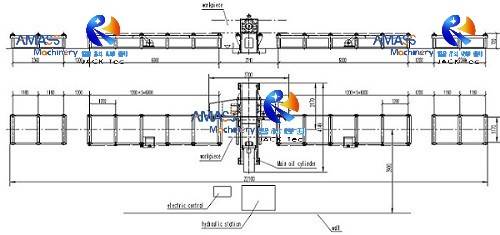

Please check below vertical view of a set of HJ series machine. It is composed of:

1) Machine frame: This is the main body of the equipment;

2) Input and Output conveyor roller table;

3) Hydraulic system: It is working energy source of the machine;

4) Electric control system.

4. Main Frame of HJ series H Beam Longitudinal Straightening Machine:

Mechanical main frame has main components of: (Fig.2)

1) Machine Bed, Transverse Beam, Pressing Head, Oil cylinder, and Supporting roller;

2) The oil cylinder is for driving the straightening execution unit---Pressing head (Point 3). In other words, it is the power source of the HJ series Longitudinal Straightening Machine; It controls movement of the pressing head by way of guiding rod;

3) The two pieces of force bearing unit Point 1 and 2 introduced in the previous product of HJ200 are in the form of moving carriage, which are installed at the front side of the transverse beam:

Straightening subject force point position management in Longitudinal Straightening Machine: (Fig.3)

4) Position of these two moving carriages (Point 1 and 2) along the guideway of the transverse beam can be adjusted manually, to control distance between them, making flexible operation of the HJ series Longitudinal Straightening Machine. As introduced in the previous product, distance adjustment is for adapting on workpiece of various sizes, and deflection status of the workpiece;

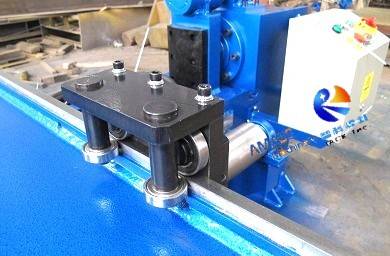

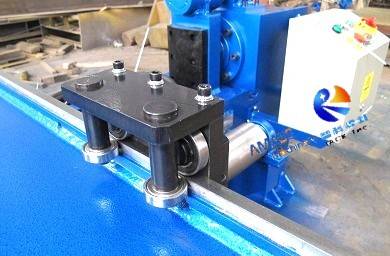

5) The moving carriages are secured by hand with bolt onto the transverse beam of the machine:

Fitting element of moving carriage in H Beam Longitudinal Straightening Machine: (Fig.4)

6) To prevent collision between workpiece and the two moving carriages, which in turn affect transport of the workpiece, two sets of pushing cylinders (Ejector One and Two mentioned in the previous section of HJ200 Longitudinal Straightening Machine), are used to push the workpiece away from the two moving carriages (Point 1 and 2). These two pieces of pushing cylinders have span of 1335mm between each other.

5. Input and Output Conveyor of HJ series Longitudinal H Beam Straightening Machine:

1) Input and output conveyors are for sending in and sending out of the workpiece;

2) Both the input and output conveyors consist of driving and idle section.;

3) Supplementary Notes on the Longitudinal Straightening Machine:

a) Layout of the HJ series machine, please see below sketch: (Fig.5)

For daily use and maintenance of the HJ series Longitudinal Straightening Machine, please check next section of HJ20 model machine.