1. What is this Product Section of H Beam Flange Straightening Machine for?

This product section covers standard models of YTJ-60, YTJ-80 and custom made hydraulic drive high power H Beam flange straightening Machine. In other words, it is a product category which involves heavy straightening force for H Beam flange with excessive thickness (60mm, 80mm and above):

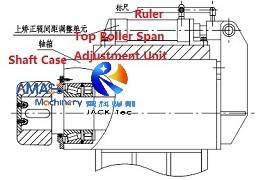

H Beam cross section in to be straightened: (Fig.1)

2. Structure of YTJ-60 and YTJ-80 High Power H Beam Straightening Machine:

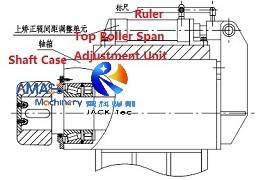

Please check below sketch:

Mechanical structure of YTJ60 and YTJ80: (Fig.2)

1) 1 is Oil cylinder for adjusting distance between the two pieces of top straightening rollers (To accommodating flange of various width);

2) 2 is Top straightening unit composed of the two pieces of rollers mentioned above. As introduced in previous product of YTJ-80, in this model of hydraulic drive H Beam Flange Straighten Machine, these two pieces of top rollers can not move along vertical direction;

3) 3 is Bottom straightening unit composed of one piece of bottom straightening roller, which moves upward and clamps against bottom surface of flange tightly during straightening operation in the machine, under the drive of hydraulic system, thus attaining the target of flange straightening. Also as introduced in previous product, this is different from the mechanical HYJ series and hydraulic YTJ-40/ YTJ-50 models equipment;

4) 4 is Main motor transmission system of 18.5~22kW (or even higher);

5) 5 is the Oil cylinder for driving the bottom straightening roller mentioned above;

6) 6 is Web Alignment and Clamp unit of the high power H Beam Flange Straightening Machine, which is also hydraulic drive. This is the other difference with mechanical and hydraulic YTJ-40&50 models. For detail, please check the next segment as below.

3. Web Alignment and Clamp unit of YTJ-60 and YTJ-80 hydraulic Automatic High Power H Beam Straightening Machine: (Fig.3)

As can be seen from the above sketch,

1) In YTJ-60 and YTJ-80 models, the two pieces of top straightening rollers are of shaft case structure, with great loading capacity;

2) Distance adjustment on the two pieces of top straightening rollers is fulfilled with hydraulic cylinder, stable and reliable, catering for varying flange width to be straightened;

3) In hydraulic drive H Beam Flange Straightening Machine, the shaft case mounting straightening rollers and their revolving shaft can slide along transverse direction integrally under drive of oil cylinder, with position displayed on the ruler above;

4) In this way, before formal operation of the machine, distance between the two pieces of top straightening rollers can be modulated, based on different flange thickness of H Beam.

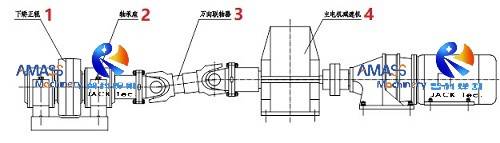

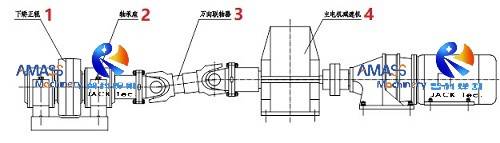

4. Mechanical Transmission System of YTJ-60 and YTJ-80 Hydraulic High Power H Beam Flange Straightening Machine: (Fig.4)

1) 1 is Bottom straightening roller of the machine;

2) 2 is Bearing pedestal of the transmission system;

3) 3 is Universal coupling of the transmission system;

4) 4 is Main motor reducer of the transmission system;

5) Critical and unique point with this transmission system is its universal couple 4, which makes the transmission system flexible along vertical direction adapting for up and down movement of the bottom straightening roller, during straightening step in the high power H Beam Flange Straightening Machine;

6) Supplementary Notes on H Beam Flange Straightening Machine:

a) As comparison, for HYJ series mechanical motor drive, please check product section of “HYJ series Conventional Mechanical Automatic”;

b) For horizontal position workpiece H Beam during straightening, please check product section of “WJ series Horizontal Hydraulic High Efficiency Automated”;

c) For H Beam lengthways straightening, please check product section of “HJ series Hydraulic High Precision Lengthways H Beam Flange Straightening Machine”.

5. Technical Parameters of YTJ-60/80 High Power H Beam Straightening Machine:

PARAMETER | Specification | NOTE |

Model | YTJ-60/80 and Custom made High Power H Beam Flange Straightening Machine |

Straightening Power | Hydraulic Pump station |

H Beam Material | Q345 | Tensile strength 510~600MPa |

Flange Thickness (s) (mm) | 6 ~ 60/80 or higher | Special-made available |

Flange Width (b) (mm) | 300 ~ 1200 |

Web Thickness (a) (mm) | ≤60 |

Web Height (h) (mm) | 500-2500 |

H Beam Length (mm) | 4000 ~ 12000 |

|

Straighten Speed (mm/min) | ≈6300 |

|

Main Motor Power (kW) | 18.5~ 22 or higher |

|

Max. Output torque (N.m.) | 48650~ 69650 |

|

Hydraulic Station Power (kW) | 11~ 15 |

|

Power Supply | 3P 380V for China | Can be made on country of customer |