Major Welding Mode in PHJ and ZHJ Series 3 in 1 H Beam Welding Machine:

1) SAW is short for Submerged Arc Welding, it is the main welding mode in manufacture on welding H Beam, which accounts for over 90% of total volume;

2) The applicable web and flange thickness for SAW welding is in the scope of 6mm to 40mm;

3) Correspondingly, majority of SAW H Beam Assembly Weld Straighten Integral Machine adopts this welding mode in its operation process.

1. SAW in PHJ H Beam Assembly Weld Straighten Integral Machine:

SAW power supply is the core unit in any set of Welding H Beam Fabrication Machine. There are 3 recommended options of brand by us to choose from as below:

1) American Lincoln brand DC series, especially DX-1000. This brand of SAW power supply has long history, public recognition, good and stable performance. Large numbers of Wuxi JACK early days exported SAW Integrated function H Beam Welding Machine (Fit Up Full H Beam Fabrication Machine) are equipped with this SAW power supply;

2) Chinese local brand HUAYUAN ZD7-1000IGBT PRO. It is a promising young product of 10s years and sees rapid development in terms of quality and market share, which is a very cost effective choice, and has gained more and more customer acceptance in the past years. Most of our domestic customers of PHJ series and ZHJ series SAW 3 in 1 H Beam Welding Machine (Welding H Beam Fabrication Machine) choose this brand of SAW power supply;

3) In recent years a new Chinese brand AOTAI welding power supply developed by team of college teachers exhibit strong growth momentum in market. It incorporates the latest development SAW technique and has superb performance, together with reasonable price, which is a very sensible choice for PHJ series and ZHJ series SAW Pull Through H Beam Welder (Welding H Beam Fabrication Machine);

4) All the above mentioned three brands of SAW power supply have demonstrated very good and persistent performance on working with our PHJ series and ZHJ series SAW Multifunction H Beam Welding Machine (H Beam Assembly Weld Straighten Integral Machine).

Besides the above mentioned three brands of SAW power supply from three suppliers, there exist many more brands of such SAW power supply, which are available working on the PHJ series and ZHJ series SAW Welding H Beam Fabrication Machine (Multifunction H Beam Welding Machine).

2. Supplement on Technical Specialties of SAW Welding H Beam Fabrication Machine:

1) SAW Quantity: One set of SAW PHJ series and ZHJ series Integrated function H Beam Welding Machine is equipped with 2 sets of SAW welding power supply, for welding left and right both sides of H Beam web at the same. And hence the 3 in 1 H Beam Welding Machine also has 2 sets of welding assistant units;

2) Welding System Composition: Every brand and model of SAW welding power is equipped with its own wire feeder and control console;

3) Welding System Position: For easy and convenient operation of SAW PHJ series and ZHJ series 3 in 1 H Beam Welding Machine (H Beam Assembly Weld Straighten Integral Machine), the 2 pieces of control consoles of the 2 sets of SAW power supply are fit together with operating panel of the Pull Through H Beam Welder, at the position alongside column of the machine gantry body, where operator manages and makes surveillance on 3 in 1 H Beam Welding Machine operation process;

4) Welding Wire Size: Depending on web thickness of the welding H Beam produced with this Fit Up Full H Beam Fabrication Machine, there are three types of welding wire in terms of diameter: Φ2.4mm, Φ3.2mm and Φ4.0mm. The welding wire is solid wire.

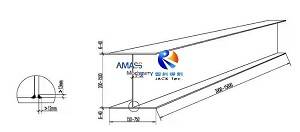

Finished welding H Beam (I Beam) from Wuxi JACK 3 in 1 H Beam Welding Machine: (Fig.1)

3. Technical Parameters of PHJ and ZHJ Integrated function H Beam Welding Machine:

Below are technical specifications of PHJ series and PHJ series SAW Integrated function H Beam Welding Machine:

Technical Parameter | PHJ15/ PHJ18/ PHJ20 | ZHJ8015/ ZHJ8018/ ZHJ8020 |

| Welding H Beam Fabrication Machine |

Web Height | 200∼1500/ 1800/ 2000 mm | 200∼1500/ 1800/ 2000 mm |

Web Thickness | 5∼30 mm | 6∼32 mm |

Flange Width | 200∼800 mm | 150∼750 mm |

Flange Thickness | 6∼40 mm |

Workpiece Length | 3000∼15000 mm |

Welding Mode | Automatic Submerged Arc Welding at flat position |

Single Pass Welding Seam Height | 8 ~ 12 mm |

Welding Assembly, Straighten Speed | 200∼1200mm/min. (Variable Frequency Drive) |

Overall Dimension of Integrated function H Beam Welding Machine Main Body(L×W×H) | 28m × 4m × (4.6m /4.9m/ 5.1m) | 28m×4m×(4.2m/ 4.5m/ 4.8m) |