From this segment we discuss the H Beam Assembly Weld Straighten Integrated Machine from the view point other than standard models.

1. Nomination of PHJ Series and ZHJ Series H Beam Assembly Weld Straighten Integrated Machine:

1) Altenative Nomination: In some countries (Such as South Asia) some customers call H Beam as “I Beam”. So, this product family has the alternative name of I H Beam Assembly Weld Straighten Integrated Machine, or I H Beam Fabrication Machine.

2) Besides, because the core step in welding H Beam production is to weld web and flanges into final product, supported with the first step of assembly and third step of straightening, we can also this Fit Up Full H Beam Fabrication Machine as Multifunction H Beam Welding Machine, or Automatic H Beam Manufacture Machine.

2. Origin and Use of PHJ Series and ZHJ Series Automatic H Beam Manufacture Machine:

1) Revolutionary Progress: This product replaces traditional H Beam Production Line of three individual machines (H Beam Assembly Machine plus Welding plus Straightening Machine) in making small and medium size welding H Beam (For Max. Welding toe size of single pass less than 12mm) since 2009. This is the reason we give the product name as Light duty 3 in 1 H Beam Welding Machine, or Light duty Fit Up Full H Beam Welding Machine;

2) Best Solution: In other words, for customers whose niche products are light duty and medium duty welding H Beam, this series of Light duty Integral H Beam Welding Equipment (Automatic H Beam Manufacture Machine) is the best choice, considering nearly all factors covering investment, facility, operator, productivity, running cost, quality, security;

3) Bright Propspect: This is the reason that by 2021, light duty Automatic H Beam Fabrication Machine has taken over 30% welding H Beam output, and witness very rapid growth in steel structure industry. It has very prosperous prospect in market share.

3. Selection on Proper Model of H Beam Assembly Weld Straighten Integrated Machine:

1) For producing heavy duty welding H Beam, (Which means, web thickness above 25~30mm, and welding seam height higher than 12mm), the conventional H Beam production line or individual machines is still the only choice;

2) The reason is, the traditional H Beam SAW machine (Gantry structure LHA, or T structure LHT, or Column structure LHC H Beam SAW Welding Machine) can perform multiple rounds of welding back and forth along the H Beam (Usually 2~3 times can meet the demand);

3) While PHJ series and or ZHJ series Automatic 3 in 1 H Beam Welding Machine (H Beam Assembly Weld Straighten Integrated Machine) usually performs single pass of SAW welding, with max. welding seam height of 12mm;

4) So, for producing welding H Beam of welding seam height 12mm and less, the Light duty PHJ series and or ZHJ series Multifunction H Beam Welding Machine is the ideal choice;

5) Factors on Affecting Selecting Proper Models of 3 in 1 H Beam Welding Machine:

Since there are several models of Light duty H Beam Fabrication Machine to choose from, for selecting proper model, below 3 factors should be considered:

a) The first is structure and size of workpiece (Welding H Beam) that is to be produced;

b) The second is prospective productivity from the 3 in 1 H Beam Assembly Weld Straighten Integrated Machine;

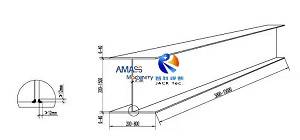

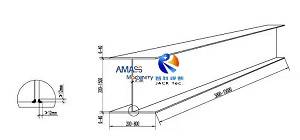

c) Cross Section: If web is joint centered with respective to flange, both PHJ and ZHJ Automatic H Beam Fabrication Machine can be selected; If there are some H Beam of which web is not centered against flange, PHJ Light duty Automatic H Beam Manufacture Machine is the only proper solution. Please check attached picture.

Welding H Beam produced from 3 in 1 H Beam Assembly Weld Straighten Integrated Machine: (Fig.1)

4. Technical Parameters of PHJ and ZHJ Multifunction H Beam Welding Machine:

Below are technical specifications of PHJ series and PHJ series Light duty Fit Up Full H Beam Fabrication Machine (H Beam Assembly Weld Straighten Integrated Machine):

Technical Parameter | PHJ15 | PHJ18 | PHJ20 | ZHJ8015 | ZHJ8018 | ZHJ8020 |

| Automatic H Beam Fabrication Machine |

Web Height | 200∼1500 mm | 200∼1800 mm | 200∼2000 mm | 200∼1500 mm | 200∼1800 mm | 200∼2000mm |

Web Thickness | 5∼30 mm | 6∼32 mm |

Flange Width | 200∼800 mm | 150∼750 mm |

Flange Thickness | 6∼40 mm |

Workpiece Length | 3000∼15000 mm |

Single Pass Welding Seam Height | 8~12 mm |

Welding Speed (Assembly, Straighten same) | 200∼1200 mm/min.(VFD) |

Machine Size(L×W×H) | 28m×4m×4.6m | 28m×4m×4.9m | 28m×4m×5.1m | 28m×4m×4.2m | 28m×4m×4.5m | 28m×4m×4.8m |