Application Focus of Wuxi JACK PHJ18 Model 3 in 1 H Beam Welding Machine:

1) Output Working Parts: PHJ18 model 3 in 1 H Beam Assembly Weld Straighten Integrated Machine is for making welding T/ I/ H Beam with web height from 200mm up to 1800mm;

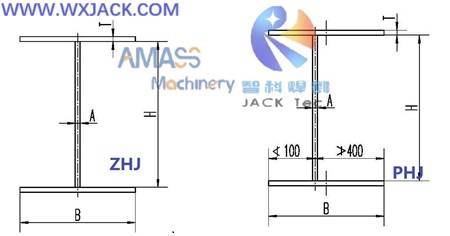

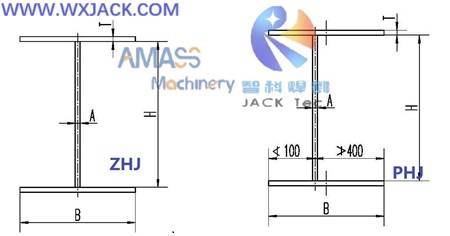

2) The cross section of finished H Beam has both symmetric and or asymmetric flange position with respect to web. (See attached and below picture):

2 Types of H Beam cross section (symmetric and asymmetric) fabricated from PHJ series H Beam Fabrication Machine: (Fig.1)

1. Main Units of PHJ18 Model 3 in 1 H Beam Assembly Welding Straightening Integrated Machine:

1) Assembly unit of PHJ18 H Beam Assembly Weld Straighten Integrated Machine:

a) Pulling Rod System: There are 3 sets of manipulators, which are driven with hydraulic station, and deployed along input conveyors of this Automatic H Beam Fabrication Machine, for carrying out first stage (rough) alignment and positioning of H Beam flange and web;

b) Automatic Alignment Unit in PHJ Model 3 in 1 H Beam Welding Machine:

There are:

(1) 6 sets of web alignment rollers, 3 sets respectively being assembled at left and right side of workpiece, totally 12 pieces of web alignment rollers;

(2) 2 sets of flange alignment rollers, 1 set each being installed at top and bottom end of workpiece,, totally 4 pieces of flange alignment rollers,

Being deployed at central working unit of PHJ series Integral Function H Beam Fabrication Machine, for implementing final (precise) alignment and positioning of H Beam flange and web (See attached picture);

2) Welding Unit of PHJ18 Model 3 in 1 H Beam Assembly Welding Straightening Integrated Machine:

a) There are 2 sets of welding power supply and flux recovery system (for SAW only) being equipped in one set of 3 in 1 H Beam Welding Machine (H Beam Assembly Weld Straighten Integrated Machine), for welding the 2 pieces of seams alongside both sides of H Beam at the same time;

b) In terms of welding mode adopted with this Automatic 3 in 1 H Beam Fabrication Equipment (H Beam Assembly Welding Straightening Integrated Machine), it can be either SAW (Submerged Arc Welding), or Gas Shielded CO2 Welding;

c) Usually SAW is used for welding thick plate in Automatic 3 in 1 H Beam Fabrication Equipment, and CO2 Welding is for welding thin plate. Rule of thumb on the threshold is 12mm H Beam flange thickness;

d) Either SAW or CO2 Welding equipped with this H Beam Assembly Weld Straighten Integrated Machine (Automatic 3 in 1 H Beam Fabrication Machine) has several options of brand to choose from;

3) Straightening Unit in PHJ18 Model 3 in 1 H Beam Assembly Weld Straighten Integrated Machine:

a) There is 1 set of flange straightening unit installed at output side of H Beam Assembly Weld Straighten Integrated Machine (Integral function H Beam Fabrication Machine);

b) It is mechanic hydraulic drive downstroke style, with strong force and easy control;

c) In Wuxi JACK PHJ and ZHJ series 3 in 1 H Beam Assembly Welding Straightening Integrated Machine, the straightening capacity is 2 times that of other companies: Max. 40mm H Beam flange thickness, compared with Max. 20mm flange thickness;

4) Input and Output Conveyors of PHJ18 H Beam Assembly Welding Straightening Integrated Machine:

a) There are 10m length input and output conveyors respectively being equipped at the incoming and outcoming side of this CO2 or SAW H Beam Fabrication Equipment (H Beam Assembly Weld Straighten Integrated Machine);

b) In standard design, both input and output conveyors have three segments respectively, of which the 1st segment is motor driving type, and the remaining two segments are follower type.

Workpiece size indications from PHJ18 H Beam Assembly Welding Straightening Integrated Machine (Fig.1)

2. Technical Parameters of PHJ18 H Beam Assembly Welding Straightening Integrated Machine:

Below are technical specifications of this PHJ18 model 3 in 1 H Beam Assembly Welding Straightening Integrated Machine:

Technical Parameter | PHJ18 Automatic Integral Function H Beam Fabrication Machine (3 in 1 H Beam Welding Machine) |

Web Height | 200 ∼ 1800 mm |

Web Thickness | 5 ∼ 30 mm |

Flange Width | 200 ∼ 800 mm |

Flange Thickness | 6 ∼ 40 mm |

Workpiece Length | 3000 ∼15000 mm |

Speed of Assembly / Welding / Straightening | 200∼1200 mm/min.(A.C. Inverter Control) |

Single Pass Welding Seam Toe Size | 8~12 mm |

Machine size(L×W×H) | 28m × 4m × 4.9m |