A. Applicable Workpiece of PHJ20 Fit Up Full H Beam Fabrication Machine:

1. Finished product of PHJ20 Automatic H Beam Welding Machine:

Welding H Beam of:

1) Max. web height 2,000mm;

2) Cross section shape of finished H Beam: Both symmetric and asymmetric alignment of web respective to flanges;

3) Related product page: Attached picture on illustration of workpiece for PHJ and ZHJ series is demonstrated in H Beam Assembly Welding Straightening Integral Machine;

2. "Label": PHJ20 model 3 in 1 H Beam Welding Machine (H Beam Fabrication Machine) is the largest model among standard ones of its product group.

B. Configuration and Operation of PHJ20 Model 3 in 1 H Beam Welding Machine:

1. Configuration of the PHJ20 Model 3 in 1 H Beam Welding Machine:

1) We give brief introduction on:

a) Structure;

b) Working units: Assembly/ Welding/ Straightening;

c) supporting units: Input/ Output conveyor;

d) Power units: Hydraulic station;

e) Control units of PHJ series Vertical H Beam Welder (H Beam Welding Machine) in the previous two product sections of PHJ15 H Beam Fabrication Machine and PHJ18 H Beam Fabrication Machine, please check;

2. Operation in the 3 in 1 H Beam Welding Machine:

1) As shown in the attached 6 pictures, operating panel of whole set of PHJ series Automatic H Beam Fabrication Equipment (H Beam Welding Machine) is put together with control consoles of its 2 sets of welding power supply, alongside column of machine gantry body;

2) In this way, operation of the H Beam Fabrication Machine is easy and convenient;

3) Strong Points: With the set up of welding parameters on control console of welding power supplies, the entire working process of PHJ series 3 in 1 H Beam Welding Machine is highly effective and fluent. Labor intensity is reduced to minimum;

3. Precondition on Proper Operation of PHJ series Vertical H Beam Welder (H Beam Welding Machine):

Pay attention to relationship between flange thickness and width produced with PHJ series Automatic H Beam Welding Machine as below:

Thickness of flange that can be straightened see below table(tensile strength σb≈400MPa):

Flange thickness T(mm) | 6~20 | 20~25 | 25~32 | 32~40 |

Flange width B(mm) | 200~800 | 450~800 | 600~800 | 700~800 |

C. Efficiency Raised with PHJ Series H Beam Fabrication Machine:

1. Working Speed Analysis: As introduced in produce section of H Beam Production Line, the working speed of H Beam Assembly Machine/ H Beam SAW Welding Machine, and H Beam Straightening Machine are:

Working Speed Comparison on 3 in 1 H Beam Welding Machine:

a) H Beam Assembly Machine for assembling and tack welding: 150 ~ 2,000 mm/min.;

b) H Beam SAW Welding Machine for submerged arc welding: 200 ~ 2,000 mm/min.;

c) H Beam Straightening Machine: Based on specific model 6,000 / 9,000 /18,000 mm/min

2. Analysis on Working Speed of H Beam Fabrication Machine Versus H Beam Production Line:

1) Major Gap: We can see that there is large gap between working speed of assembling and welding with respect to straightening;

2) Which means, the conventional H Beam Straightening Machine have lots of time in idle condition, waiting for H Beam SAW Welding Machine completion operation;

3) The corresponded line balance is at worse condition for traditional H Beam Production Line than that of PHJ series 3 in 1 H Beam Welding Machine, which makes uniform speed of H Beam assembly/ welding and straightening;

4) Ideal Line Balance Rate Acquired from H Beam Fabrication Machine: This is the reason workshop installed with PHJ series Fit Up Full H Beam Fabrication Machine usually sees smooth running of manufacturing flow.

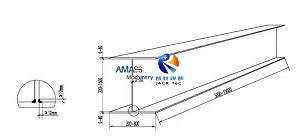

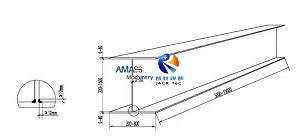

Finished welding H Beam from 3 in 1 H Beam Welding Machine: (Fig.1)

D. Technical Parameters of PHJ20 Model 3 in 1 H Beam Welding Machine:

Below are technical specifications of PHJ20 model Integrated Function Automatic H Beam Welding Machine:

Technical Parameter | PHJ20 Fit Up Full H Beam Fabrication Machine |

Web Height | 200 ∼ 2000 mm |

Web Thickness | 5 ∼ 30 mm |

Flange Width | 200 ∼ 800 mm |

Flange Thickness | 6 ∼ 40 mm |

Workpiece (Welding H Beam) Length | 3000 ∼ 15000mm (At customer demand) |

Working Speed of Assembly/ Welding Straightening | 200∼1200 mm/min. (Variable Frequency Drive) |

Height of Single Pass Welding Seam | 8~12 mm |

Workpiece (Welding H Beam) Cross Section | Symmetric and Asymmetric both |

Overall Dimension of PHJ20 3 in 1 H Beam Fabrication Machine (L×W×H) | 28m × 4m × 5.1m |

Driving Mode | Assembly/ Straightening: Hydraulic; Welding: Electric |

Operator | 1 ~ 1.5 (1.5 means a part time support) |