The attached photos shows a set of PHJ15 Universal Use 3 in 1 H Beam Fabrication Machine produced and exported by Wuxi JACK to a customer in Russia.

1. Outline on PHJ15 Model 3 in 1 H Beam Fabrication Machine:

1) Strong Capability: PHJ15 model 3 in 1 I Beam Assembly Weld Straighten Integral Machine is very popular in overseas market. It has universal application in making H Beam/ I Beam/ T Beam of nearly all structure members, including symmetric and asymmetric cross section shape. The workpiece size falls within the scope of standard size raw materials in steel structure use: Web height in the range of 200mm to 1500mm;

2) General process technology: The attached 2nd and 3rd photos were taken on the PHJ series Integral function H Beam Welding Machine in the process of making welding H Beam and T Beam respectively. For making H Beam/ I Beam, the workpiece needs to go thru this Pull Through Beam Welder two times, the first time into T Beam, the second time into H Beam (I Beam);

3) Working mode: In a nutshell, PHJ series SAW H Beam Welding Machine (SAW T Beam welding Machine) manufactures workpieces with the three consecutive steps of fitting up/ welding/ straightening, under the hybrid driving mode of hydraulic and electric motor drive;

4) Automatic operation: Except material handling and one site adjustment for flange alignment and web alignment, all the other jobs in this Integrated H Beam Welding Machine are automatic. It is an equipment of sophisticated and delicate design, high degree of automation, easy and user friendly operation.

2. Composition of PHJ15 Model Integrated H Beam Welding Machine:

1) Lean production at Wuxi JACK: Due to its popular use and large selling volume, the PHJ15 I Beam Assembly Weld Straighten Integral Machine usually is made in batch production, as is shown in the 4th photo. There are 4 sets of PHJ15 Integrated H Beam Welding Machine ready for shipment;

2) Main Units of 3 in 1 H Beam Fabrication Machine:

This photo also gives clue on the general composition of the PHJ series product, that one set of such 3 in 1 H Beam Fabrication Machine is composed of:

a) Mechanical main body;

b) Input and output conveyors;

c) Function units: Hydraulic pump station/ 2 sets of SAW power supply/ Control cabinet;

3) Mechanical system: And going further, mechanical main body of this Pull Through Beam Welder has two main parts of base bed (In front in the 3rd photo) and U shape gantry beam (In rear);

4) More explicitly the structure of the Integral function H Beam Welding Machine is shown in the 5th photo, that it can be taken as exploded view of the equipment:

5) Structure of Wuxi JACK 3 in 1 H I Beam Assembly Weld Straighten Integral Machine:

a) Central View: In the front (The left most) is base bed of the 3 in 1 H Beam Fabrication Machine, it integrates the working cells of assembling/ welding/ straightening;

b) Assembly Section: This photo was taken at the inlet side (Assembling) of the Pull Through Beam Welder. The assembling cell can be checked very plainly in the 3rd photo, which consists of three pairs of web alignment rollers (4 roller each pair, totally 12 pieces of alignment rollers) in 1 set of the H I Beam Assembly Weld Straighten Integral Machine;

c) Assembly Style: Each pair of the alignment rollers clamp on the H Beam web firmly, making it aligned with centerline of the SAW H Beam Welding Machine (T Beam Welding Machine);

6) Flange Assembly in Integrated H Beam Welding Machine:

a) There are another 2 pairs of flange alignment rollers, which, due to its lower assembled position, can not be identified very clearly in this vertical view of the working area, but can be seen in the 2nd photo;

b) Please check the edges of bottom flange, there are fitting up rollers leaning against it at its both edges, during operation of the I Beam Assembly Weld Straighten Integral Machine;

c) These tells the fitting up (assembling) principle of the Integrated H Beam Welding Machine. These flange and web alignment rollers are hydraulic drive;

7) Usage of Hydraulic Manipulators in Integral function H Beam Welding Machine:

a) Assembled position: Back to the 5th photo. In the middle, the yellow color claws with blue color box are input manipulators. There are three sets of such manipulator in one set of PHJ15 model 3 in 1 H Beam Fabrication Machine, which are deployed at input conveyor of the machine;

b) Function: These hydraulic drive manipulators are for supporting the raw materials of H Beam/ T Beam and making it aligning with centerline of the Pull Through Beam Welder during the feeding in step of operation;

8) U Gantry Frame in H I Beam Assembly Weld Straighten Integral Machine:

a) Appearance: In the farthest (The right most) in the 5th photo is the mechanical gantry beam of the Integral function H Beam Welding Machine;

b) Position and Assembly Style: This U frame gantry forms the upper section of SAW H Beam Welding Machine mechanical main body, which is assembled with base bed by means of two square shape connecting boards and 20 pieces of high strength bolts. The fitting torque is strictly managed;

9) In the 5th photo a set of H Beam End Face Milling Machine can be seen for its upper section (The equipment closes to window). It is another superior product of Wuxi JACK. This machine is for performing end face milling on welding H Beam produced from I Beam Assembly Weld Straighten Integral Machine. So, it is sibling product of PHJ series Integral function H Beam Welding Machine.

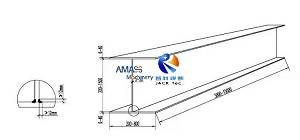

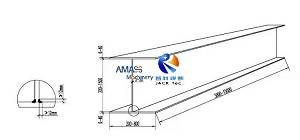

Finished welding H Beam from I Beam Assembly Weld Straighten Integral Machine: (Fig.1)

3. Technical Parameters of PHJ15 Model 3 in 1 I Beam Assembly Weld Straighten Integral Machine:

Below are major specifications of this PHJ15 model Integral function H Beam Welding Machine (T Beam welding Machine):

Technical Parameter | PHJ15 Universal Use 3 in 1 I Beam Fabrication Machine (H Beam Fabrication Machine) |

Web Height | 200 ∼ 1,500 mm |

Web Thickness | 5 ∼ 30 mm |

Flange Width | 0.2 ∼ 0.8 m |

Flange Thickness | 6 ∼ 40 mm |

Workpiece (Welding H Beam) Length | 3,000 ∼ 15,000 mm (Can be tailor made) |

Working Speed of Assembly/ Welding and Straightening | In the range of 200 ∼1,200 mm/min.; Recommended working speed is 500~700mm/min. (Stepless, A.C. inverter control) |

Welding Seam Toe Size | Single Pass of max. size 8~12 mm |

Finished Workpiece | Symmetric and Asymmetric Section-Shape Welding H Beam/ I Beam/ T Beam |

Machine Overall Dimension(L×W×H) | 28m × 4m × 4.6m |

Input and Output Conveyor | 10~11m length in 3 segments each; One segment is driven with motor, and the other two segments are followers; Input conveyor is equipped with 3 sets of hydraulic manipulators |

Driving Mode | Assembly/ Straightening/ Output conveyor elevation: Hydraulic cylinder |

Welding Mode | Single Arc or Twin Arc SAW at fillet flat position |

Hydraulic Pressure | 6~ 8 MPa |

Flange and web Fitting Up Way | One side hydraulic cylinder, the other side manual handwheel for turning leadscrew |