1. Usage of HJ20 Lengthways H Beam Straightening Machine:

1) HJ20 is the smallest model of the HJ series hydraulic Length Direction H Beam Straightening Machine: (Fig.1)

2) It has same Straightening principle, Machine structure, and Operation as HJ300, and HJ200, and HJ100 Lengthwise H Beam Straightening Machine, which have been covered in the previous sections;

3) In this section of HJ20, we will have an introduction on Operation Precaution and Trial Run of the HJ series Lengthways I Beam Straightening Machine.

2. Operation Precaution of HJ series Length Direction H Beam Straightening Machine:

HJ series is a mature product with intuitive and user friendly operation. On the other hand, there are several points for attention on its normal working:

Straightening working unit of Wuxi JACK HJ100 Lengthways H Beam Straightening Machine (Fig.2)

1) Pressing Head (Point3) and the two Moving carriages (Point 1&2) on the Transverse Beam of the HJ series Lengthwise H Beam Straightening Machine:

a) These are straightening execution unit of the HJ Lengthwise I Beam Straightening Machine;

b) They are made of the material 35 molybdenum complex, and went thru heat treatment, with sufficient strength to withstand repeat straightening job on daily basis;

c) These components have same service life as the HJ series Lengthwise H Beam Straightening Machine itself, and do not need to be replaced under normal condition;

d) On the other hand, to have a reasonable and thoughtful maintenance on these units, is a great contributing factor on stable and consistent running of the HJ series Length Direction I Beam Straightening Machine;

2) Before advance and retreat of input and output conveyor, be sure to make H Beam away from the two moving carriages (Point 1 and 2) and pushing cylinders (Ejector One and Two):

Workpiece holding unit in Wuxi JACK Lengthways H Beam Straightening Machine: (Fig.3)

3) Before straightening in the HJ series Lengthwise H Beam Straightening Machine, be sure to retract pushing cylinder, otherwise the cylinder may be damaged:

Oil cylinder in Wuxi JACK Length Direction H Beam Straightening Machine: (Fig.4)

4) Before operation, adjust height of supporting rollers of mainframe, making H Beam web at the same level as the straightening driving cylinders of the HJ series hydraulic Lengthways I Beam Straightening Machine.

3. Trial Run of the HJ series Lengthwise H Beam Straightening Machine:

1) Before Trial Run of the HJ series Lengthways H Beam Straightening Machine:

a) Perform trial-idle-run on this Length Direction H Beam Straightening Machine, making sure normal condition of all components and parts, and all transmission units are applied with lubricating oil or grease;

b) Start conveyor motor both in Forward and Reverse directions three times repeatedly, making sure its normal running for the Lengthwise H Beam Straightening Machine;

c) In inching mode, check and make sure revolve direction of oil pump motor is identical with the sign indicated on the fan. Then start on the motor, and regulate hydraulic pressure to around 10Mpa. After four minutes idle running, start all cylinders in inching mode five times repeatedly to check they are in normal condition;

d) Trial production of the HJ series Lengthways I Beam Straightening Machine can begin after confirming all are in normal condition;

2) In Trial Run of the Lengthwise H Beam Straightening Machine:

a) Manually regulate distance between the two moving carriages along the transverse beam, and secure its with bolts manually at completion of adjustment:

Straightening segment length adjustment in Length Direction H Beam Straightening Machine: (Fig.5)

b) Hoist H Beam or other kinds of workpiece (Structure Member, Section Steel) onto input conveyor with travel crane, pressing “FORWARD” button, advancing H Beam to straightening section:

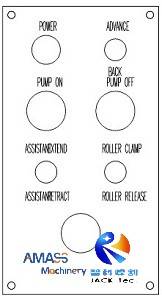

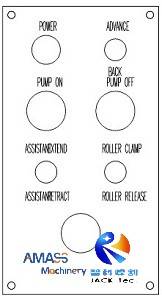

Operating pendant of Lengthwise H Beam Straightening Machine: (Fig.6)

c) Press “Press and Straightening” button, driving the pressing head by means of oil cylinder to straighten workpiece in the HJ series Lengthwise H Beam Straightening Machine;

d) At completion of straightening, press “Release” button, the pressing head retracts driven with oil cylinder again;

e) Press “Auxiliary Extend” button, pushing workpiece away from straightening supporting block (The two Ejectors); Then press “Auxiliary Shrink” button, and retract the cylinders;

f) Press “Advance” button, workpiece travels forward in certain distance in the HJ series Lengthways H Beam Straightening Machine;

g) Repeat the above mentioned steps, until completing straightening task along whole length of the workpiece.